Single equipment quality evaluation method based on fault probability and equipment state

A technology of failure probability and quality evaluation, applied in instruments, manufacturing computing systems, data processing applications, etc., can solve the problems of not considering state change data, inaccurate and precise, and difficult to reflect random factors, and achieve accurate prediction results. Evaluate accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]The technology of the present invention will be described in detail below in combination with specific embodiments. It should be known that the following specific embodiments are only used to help those skilled in the art understand the present invention, rather than limiting the present invention.

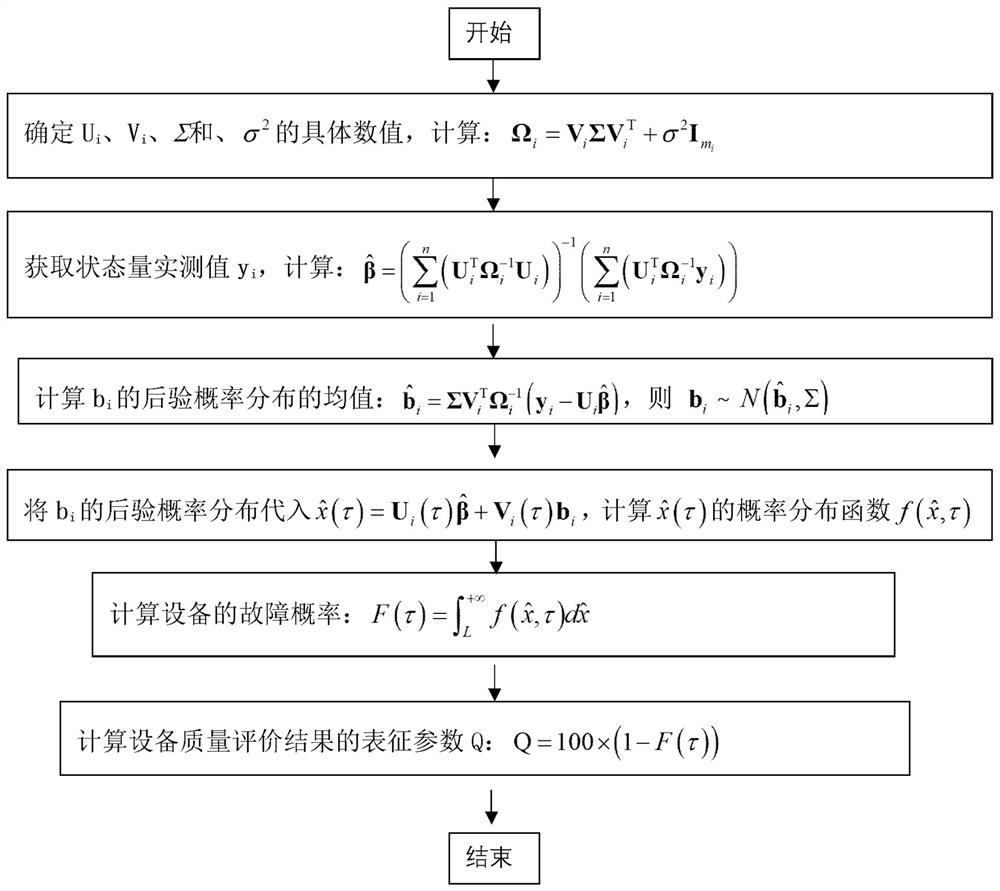

[0038] This embodiment is a method for evaluating the quality of a single piece of equipment based on failure probability and equipment status, such as figure 1 shown, which includes:

[0039] In the first step, it is assumed that the deterioration of the state quantity x of the equipment with time conforms to the linear law expressed by the formula (1), even if the state quantity x does not change linearly with time, it can be transformed into a time-linear Amount of change:

[0040] the y i =x i +ε i =U i β+V i b i +ε i (1)

[0041] In the above formula, Indicates the actual state quantity degradation value of the i-th device; Indicates the measured value of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com