A qcm experimental system capable of adjusting different working conditions and its adjustment method

An experimental system and adjustable technology, applied in the field of research on the characteristics of pollutants in wind tunnels, can solve the problems of changing aerodynamic data and increasing experimental costs, and achieve the effect of precise temperature adjustment and uniform heat conduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

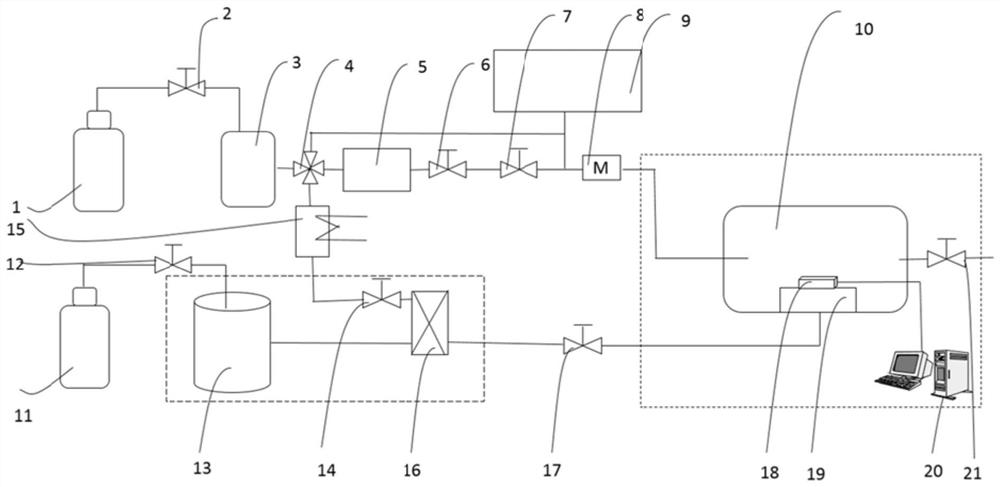

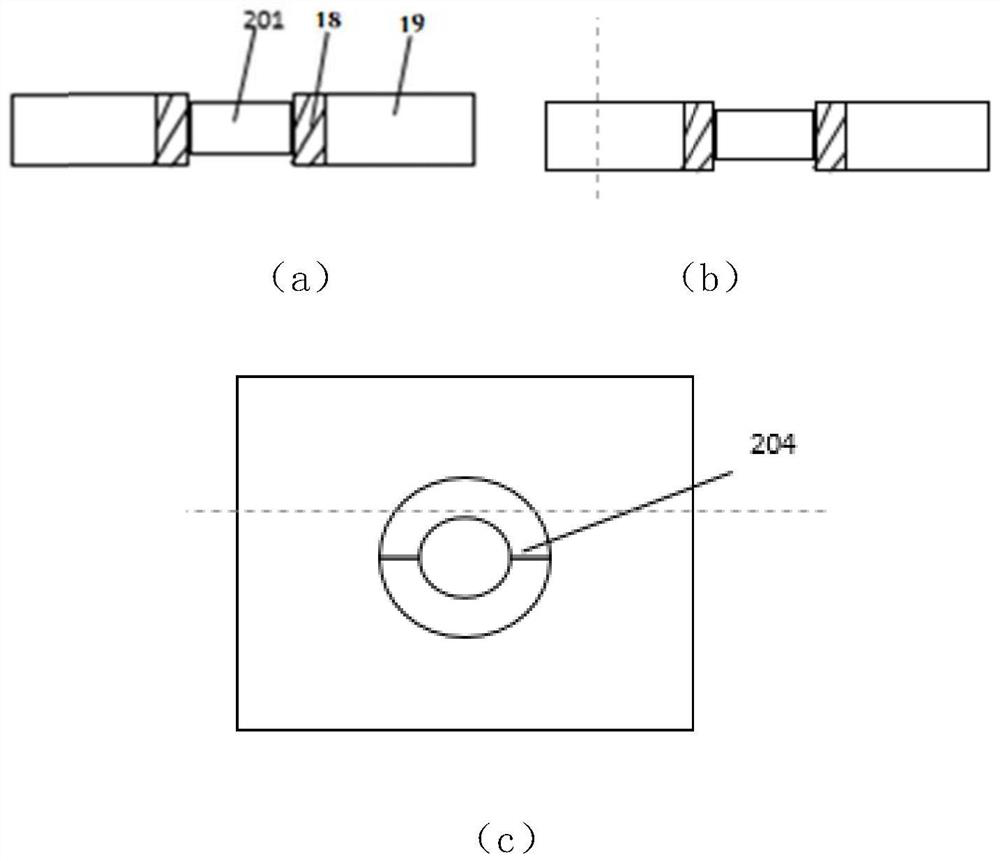

[0031] see figure 1 , the QCM experimental system capable of adjusting different working conditions in this embodiment includes a sealed cavity 10 , a pressure and composition adjustment unit, a temperature control unit, and a data acquisition unit 20 .

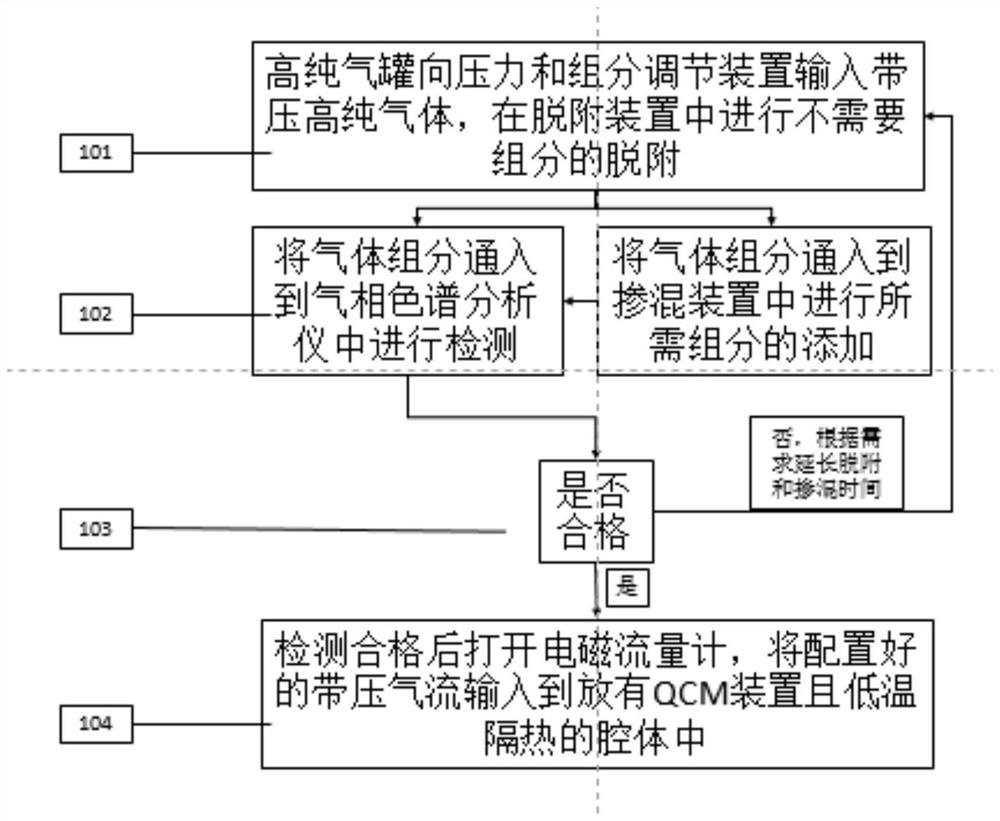

[0032] In the pressure and component adjustment unit, the high-purity gas tank 1 is used to output the gas source containing pressure flow through a secondary pressure reducing valve 2; Drainage through the four-way valve 4 to the gas chromatograph 9 for primary concentration analysis of the pressure gas; the middle branch carries out secondary concentration analysis of the pressure gas blended by the blending device 5; the back-end branch is connected to the electric heater 15 to The diverted gas from the high-purity gas tank 1 is preheated and guided to the heat exchanger 16 through the safety valve 14. The form of the heat exchanger 16 is not fixed. It is recommended to use a tube-fin heat exchanger to increase the heat ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com