A pressure differential plunger automatic pressure regulating valve

An automatic pressure regulation and plunger technology, applied in the field of pressure regulating valves, can solve the problems of low adjustment accuracy, incomplete application of liquid media, single function, etc., and achieve the effect of rapid and accurate control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

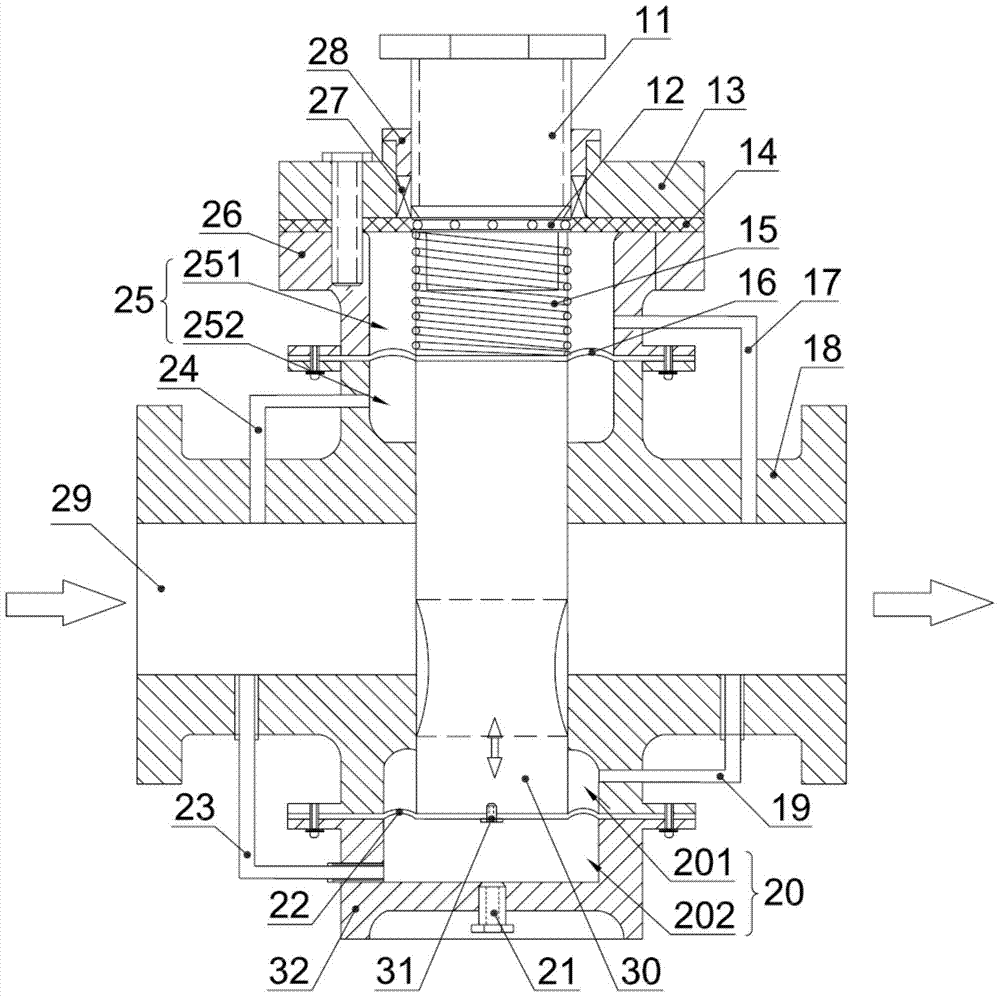

[0019] refer to figure 1 , a pressure differential plunger automatic pressure regulating valve, including a valve body 18, a medium passage 29 located in the valve body 18, and a plunger body 30 arranged in the valve body 18 and intersecting with the medium passage 29, the plunger body 30 The upper valve body 18 is provided with an upper chamber 25, the upper chamber 25 is provided with an upper diaphragm 16, and the upper diaphragm 16 divides the upper chamber 25 into a first upper chamber 251 at the upper part of the upper diaphragm 16, And the second upper chamber 252 at the bottom of the upper diaphragm 16, the lower surface of the upper diaphragm 16 is fixedly connected with the upper end surface of the plunger body 30, and the upper surface of the upper diaphragm 16 is fixedly connected with an elastic member 15, and the elastic member 15 is preferably It is a spring, and the other end of the elastic member 15 is connected with a relatively rotatable pressure-adjusting b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com