Two-way autorotation type oil-gas multiphase pump

A technology of oil-gas mixed pump and rotating shaft, which is applied in the direction of non-variable pumps, pumps, machines/engines, etc., which can solve the problems of large vibration and noise, long axial length of mixed pump, and large volume of pump body, and achieve noise reduction. Reduce, ensure stable operation, high speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

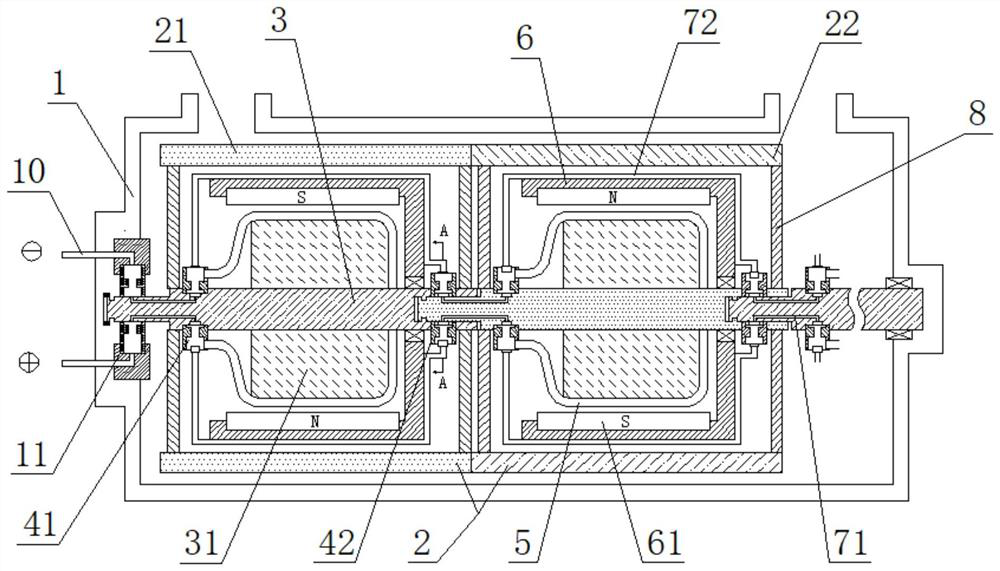

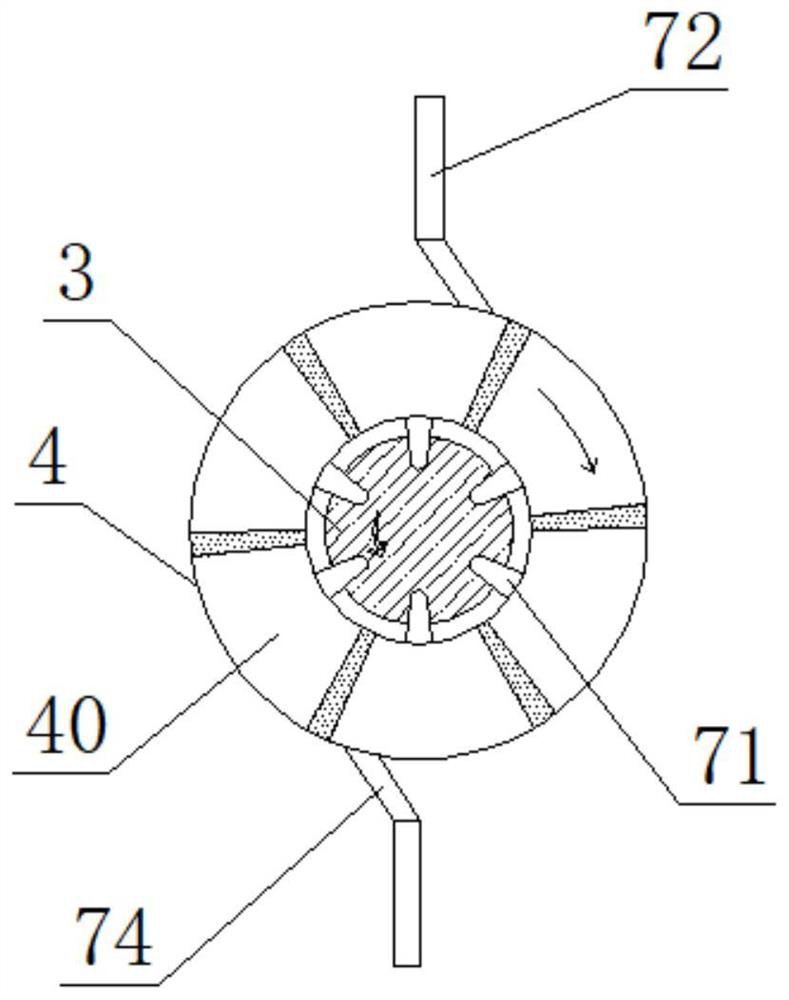

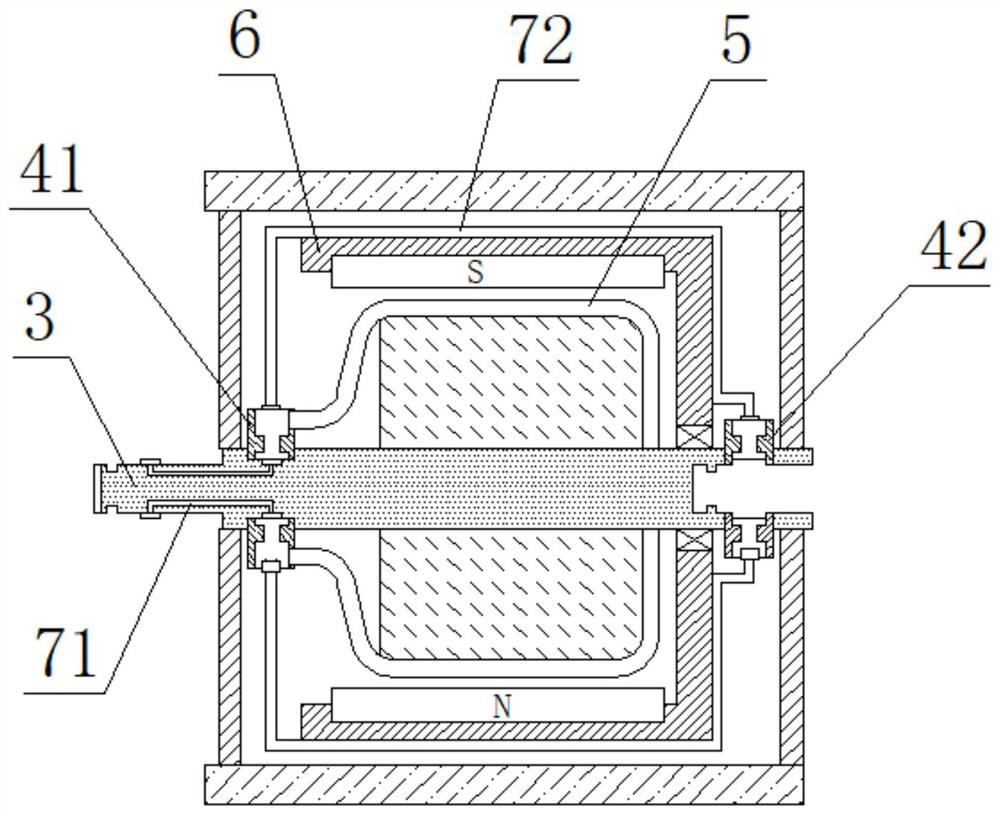

[0018] Such as Figure 1-5 As shown, a two-way self-rotating oil-gas mixed delivery pump includes a pump body 1, a connecting shaft and an impeller 2 located in the pump body 1, wherein a power line 10 is provided at the front end of the pump body 1, and the connecting shaft is It consists of a number of rotating shafts 3, and a rotary socket is used between two adjacent rotating shafts 3. A commutator 4 is provided at both ends of the rotating shaft 3. The front end of the rotating shaft 3 is a front commutator 41, and the rear of the rotating shaft 3 The rear commutator 42 at the end is provided with an iron core 31 in the middle of the rotating shaft 3, and several groups of coils 5 are wound on the iron core 31, and the two ends of the coil 5 are connected with the front commutator 41. The conductor 40 is connected, and the inner casing 6 is connected to the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com