Hinge structure for automobile trunk lid and automobile

A hinge structure and trunk lid technology, applied in the automotive field, can solve the problems of increasing the damping force of the trunk lid, reducing the opening speed, and large closing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

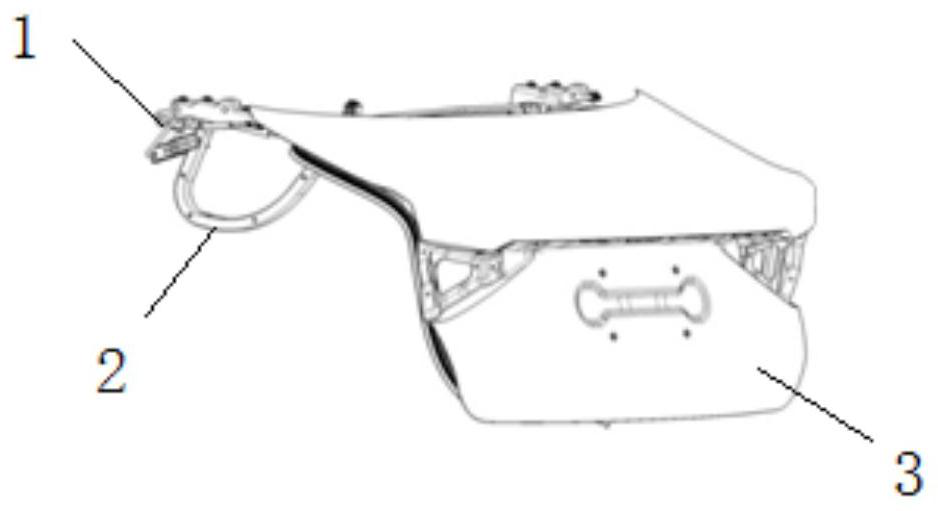

[0053] figure 1 It shows the installation schematic diagram of the hinge structure used for the trunk lid of the automobile in this embodiment. The active force provided by the torsion spring 1 and the reaction force provided by the hinge structure 2 solve the problem that the opening speed of the lid 3 is too fast and the closing force is large. The problem of the case lid 3 is directly bounced to the highest when it is opened, and the purpose of increasing the active force applied to the case lid 3 is not needed when closing.

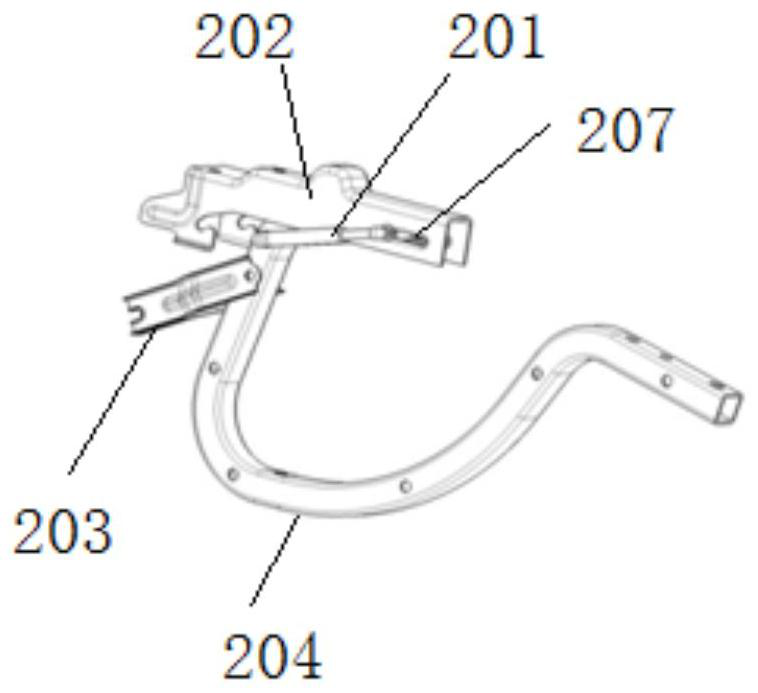

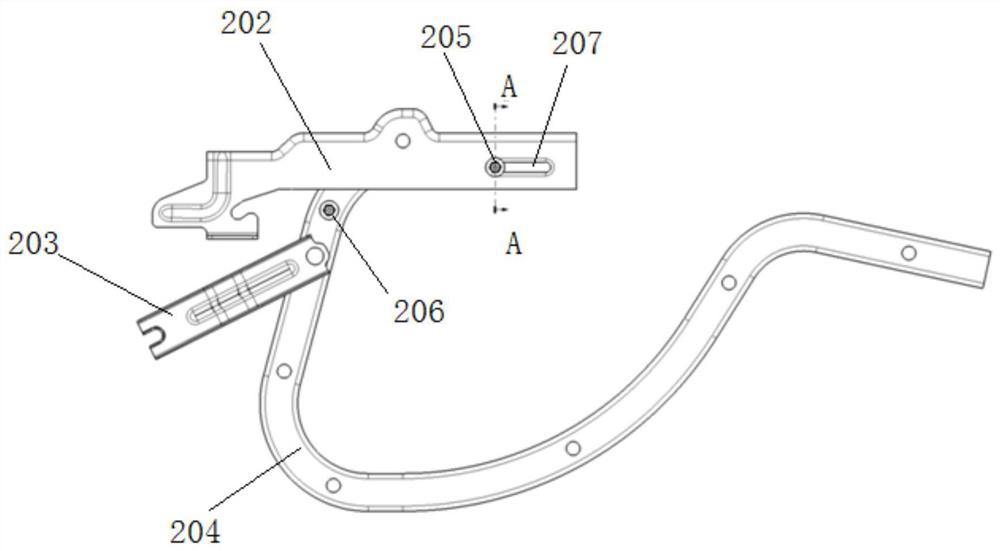

[0054] Such as figure 2 As shown, the hinge structure 1 of the present embodiment comprises a damping element 201, a hinge holder 202, a hinge arm 204, a connecting plate 203, a damping element 201, the hinge holder 202 is used to connect the trunk of a car, and the hinge arm 204 One end is hinged to the hinge holder 202, and the other end is used to connect the case cover 3 of the trunk of the car. One end of the connecting plate 203 is hinged to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com