A simple sandwich type composite structure energy storage fragment and its preparation method

A composite structure and interlayer technology, applied in the field of energetic materials and active fragment materials, can solve the problems of enhancing the damage effect, increasing the contact area of a single fragment, and not taking into account, so as to achieve enhanced damage effect, low cost and high power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

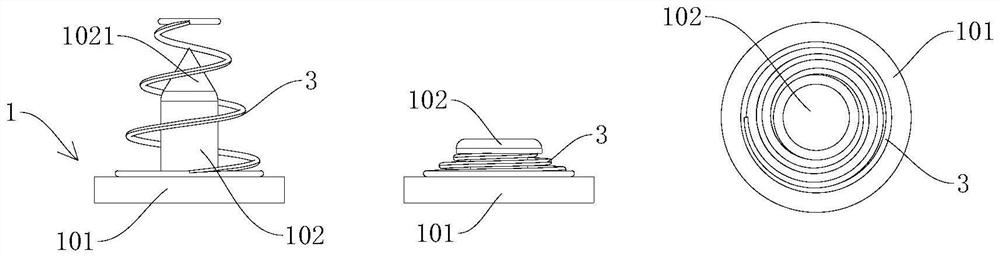

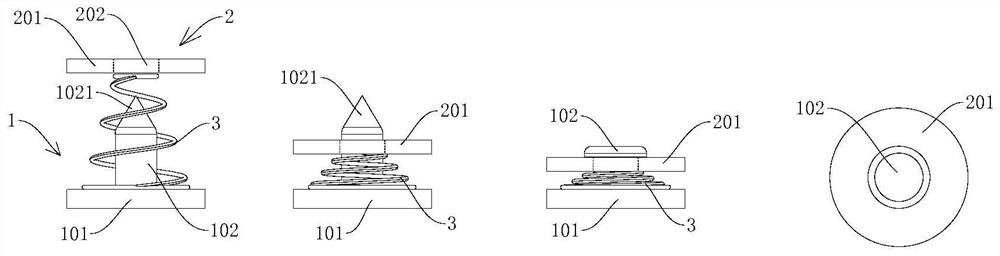

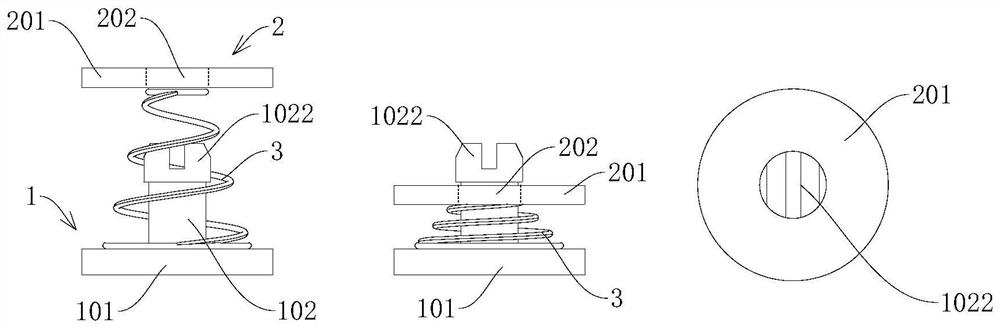

[0029] see Figure 1-3 , a simple sandwich-type composite structure energy storage fragment, including a spiral structure A1, an active energy-containing structure B2 and a tower spring 3, the stretchable spiral structure A1 includes a connecting base 101, and the connecting base 101 is fixedly connected with A fixed rod 102, 3 sets of tower springs are connected to the fixed rod 102, the active energetic structure B2 includes a fixed disc 201, the center of the fixed disc 201 is provided with a through hole 202, the diameter of the through hole 202 is larger than that of the fixed rod 102 in diameter.

[0030] The top of the fixing rod 102 is fixedly connected with a pointed rod head 1021 or a retractable buckle-type rod head 1022 , and the pointed rod head 1021 or shrinkable buckle-type rod head 1022 is matched with the through hole 202 . .

[0031] Compared with the single inert fragments or metal / polytetrafluoroethylene active fragments reported in the past, the energy s...

Embodiment 2

[0033] see Figure 1-4 , combined with the basis of Example 1, the difference is that a simple sandwich type composite structure energy storage fragment preparation method, the specific steps are as follows:

[0034] Step 1: Prepare a steel wire with good high temperature ablation resistance, toughness and plasticity through a reasonable ratio of each element, and obtain a stretchable spiral structure A1 through winding, heat treatment and elastic performance testing;

[0035] Step 2: Put active metal / inert metal filler / polytetrafluoroethylene powder in an all-round planetary ball mill to mix and mix, and place it in a specific molding mold for pressing and sintering to obtain a "rivet" fixing function Active energetic structure B2;

[0036] Step 3: Place the tower spring 3 on the fixed rod 102 of the telescopic spiral structure A1, compress the tower spring 3 downward, and then melt the pointed head 1021 of the fixed rod 102 with a hot-melt device until The pointed rod head...

Embodiment 3

[0043] Based on Example 1-2 but different in that,

[0044] (1) Prepare a stretchable spiral structure A;

[0045] Preparation of steel wire with high temperature ablation resistance, toughness and plasticity:

[0046] C=0.08%, Mn=2.00%, P=0.035%, S=0.015%, Si=0.75%, Cr=18.00%, Ni=8.00%, N=0.10%, Fe=71.02%.

[0047] A stretchable helical structure A is obtained by winding, heat-treating, and testing the elastic properties of the above-mentioned steel wire.

[0048] (2) Preparation of sandwich composite structure energy storage fragments.

[0049] Powder mixing: the mass ratio of each component is: aluminum powder / magnesium powder / tungsten powder / PTFE=10 / 10 / 30 / 50, that is, weigh 10g of aluminum powder, 10g of magnesium powder, 30g of tungsten powder, PTFE 50g of ethylene powder, dried, placed in an all-round planetary ball mill and mixed for 2h, rotating speed 200rpm / min, mixed evenly;

[0050] Molding: Add the above-mentioned uniformly mixed powder into a special molding m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com