Plant cleaning system for plant shampoo processing

A cleaning system and shampoo technology, applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of slow efficiency and mixing into plants, and achieve multi-benefit and labor-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

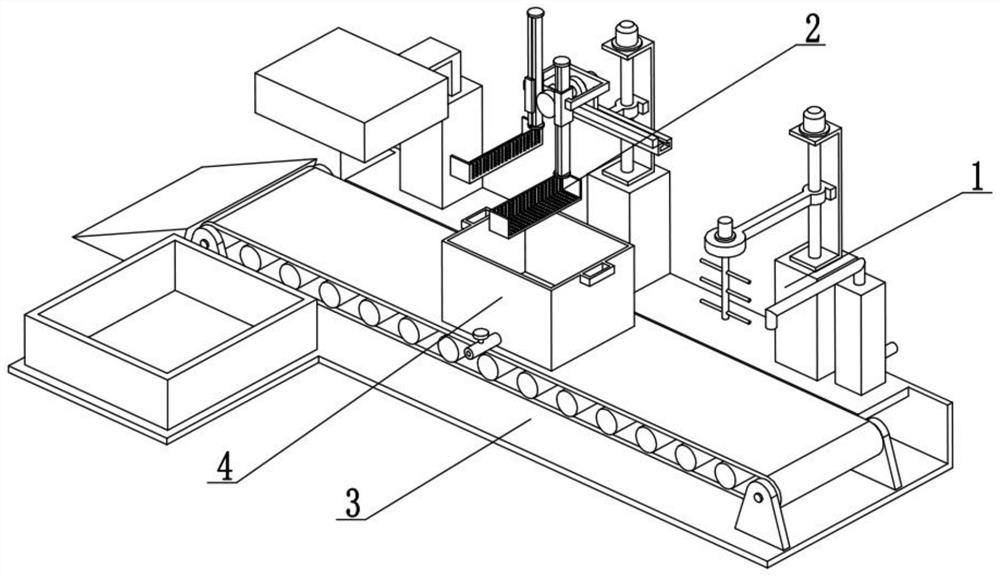

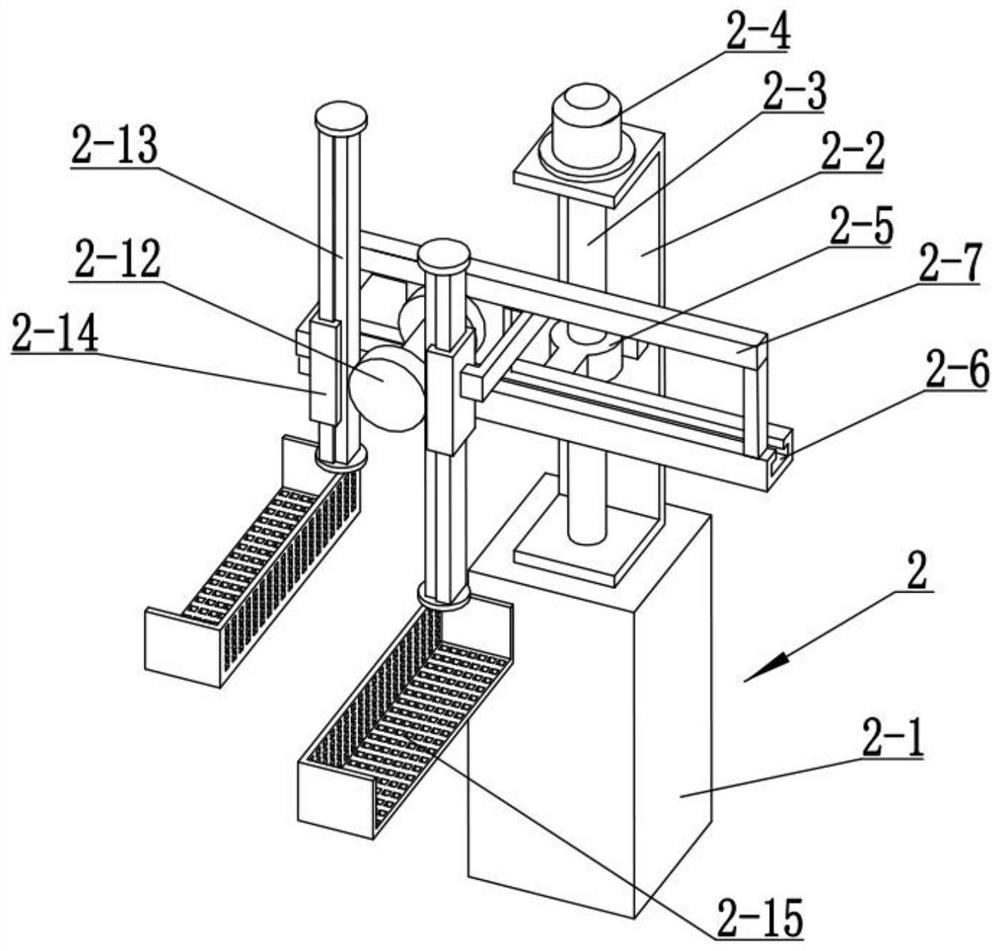

[0025] The present embodiment will be described below in conjunction with the drawings. The present invention relates to the technical field of shampoo processing, more specifically a plant cleaning system for plant shampoo processing, including an agitating cleaning mechanism 1, a scum fishing mechanism 2, a transport platform mechanism 3 and The plant cleaning bucket 4, the agitation cleaning mechanism 1 is connected to the right end of the transport platform mechanism 3 rear end, the scum salvage mechanism 2 is connected to the middle part of the transport platform mechanism 3 rear end, and the plant cleaning bucket 4 is located on the transport platform mechanism 3.

[0026] There are multiple plant cleaning buckets 4, and the plants used for shampoo processing are packed into a plurality of plant cleaning buckets 4, and placed one by one on the transport platform mechanism 3, when each plant cleaning bucket 4 passes under the stirring cleaning mechanism 1 , the agitating c...

specific Embodiment approach 2

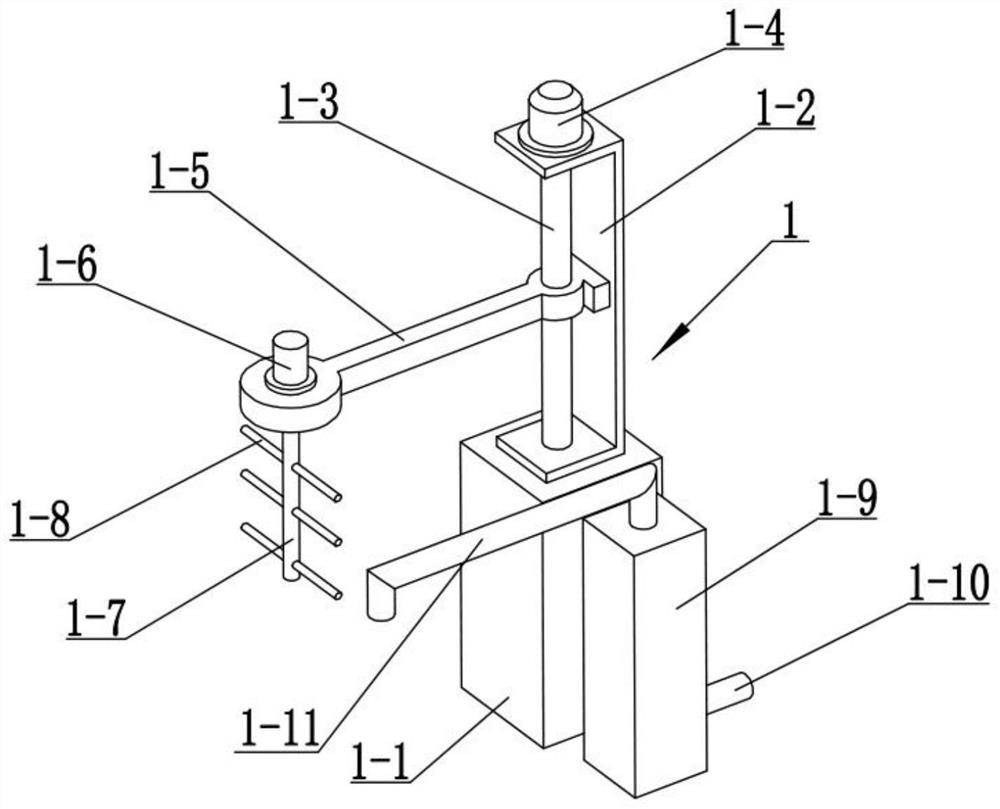

[0028] The present embodiment will be described below in conjunction with the drawings. This embodiment will further illustrate the first embodiment. The agitation cleaning mechanism 1 includes a height base 1-1, a vertical slideway 1-2, a vertical screw rod 1-3, a vertical Motor 1-4, lifting beam 1-5, stirring motor 1-6, rotating shaft 1-7 and stirring rod 1-8, a plurality of stirring rods 1-8 are all fixedly connected on the rotating shaft 1-7, and rotating shaft 1 The top of -7 is rotatably connected to the bottom end of the front end of the lifting beam 1-5, the rotating shaft 1-7 is fixedly connected to the output shaft of the stirring motor 1-6, and the stirring motor 1-6 is fixedly connected to the front end of the lifting beam 1-5, The rear end of the lifting beam 1-5 is threadedly connected to the vertical screw mandrel 1-3, the vertical screw mandrel 1-3 is rotatably connected to the vertical slideway 1-2, and the top of the vertical screw mandrel 1-3 is fixedly conne...

specific Embodiment approach 3

[0031]The present embodiment will be described below in conjunction with the drawings. This embodiment will further illustrate the second embodiment. The rear end of the lifting beam 1-5 is a planar structure, and the planar structure is used to match the rear end of the lifting beam 1-5 with the vertical The slideway 1-2 is in sliding contact; the lifting beam 1-5 is prevented from rotating following the vertical screw rod 1-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com