Round pipeline paint sprayer with quick drying function for round hollow pipe

A fast-drying, hollow-pipe technology, applied in paint spraying booths, spraying devices, and devices for coating liquid on the surface, can solve problems such as slow drying of paint on the outer wall of the pipe, easy dripping of condensation beads, and affecting the efficiency of the finished product of the pipe, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

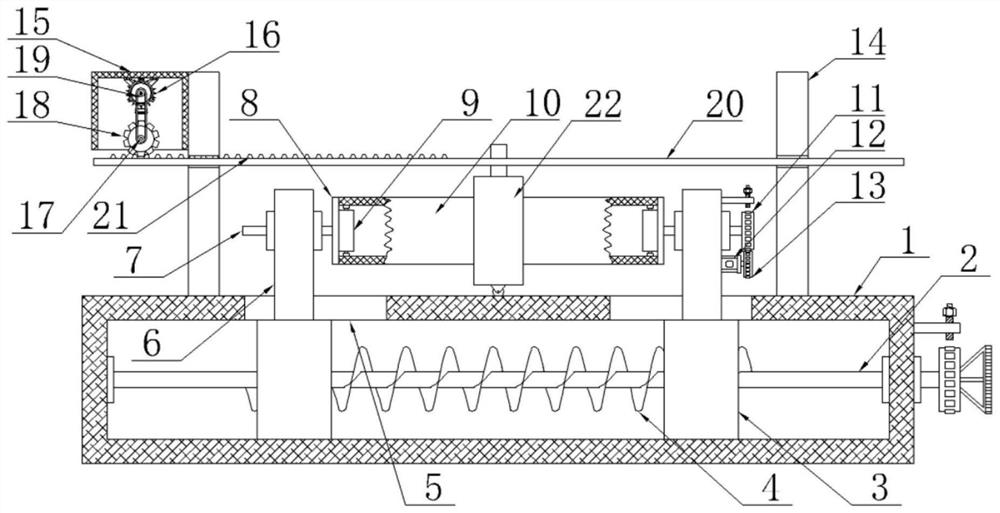

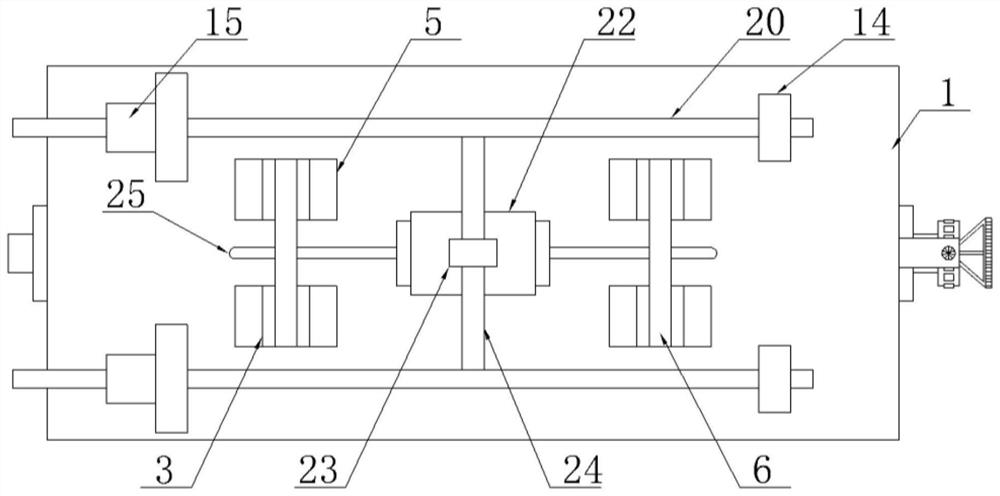

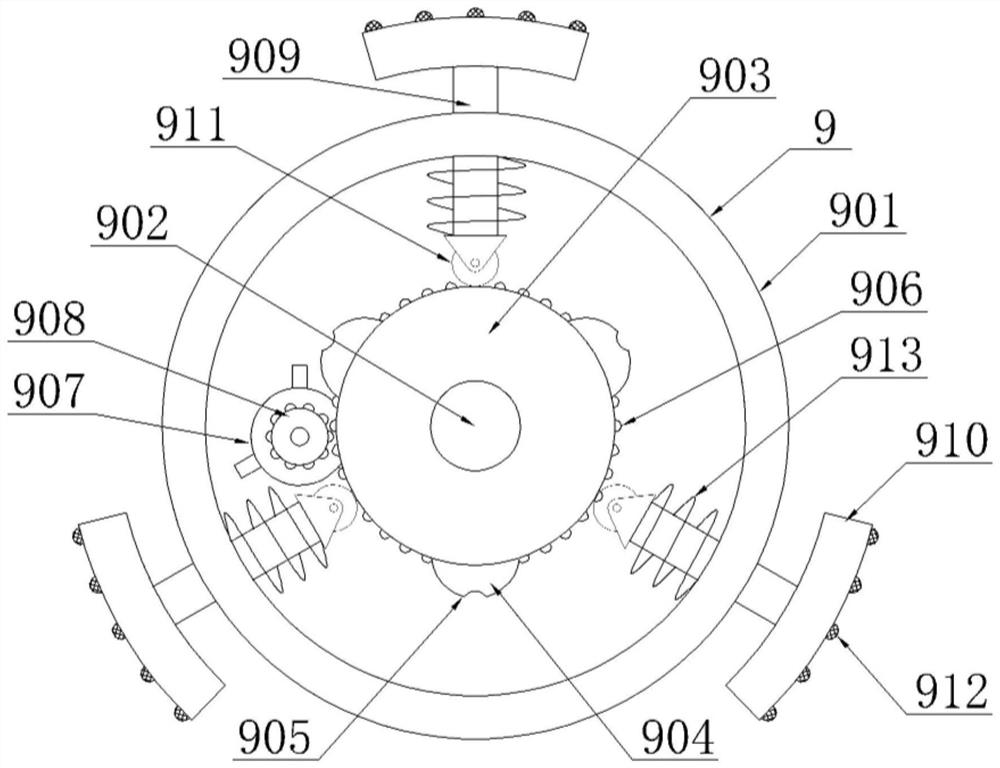

[0029] 1) Fixing of the pipeline: Turn the lever 2 by hand to make the two groups of movable blocks 3 approach each other, put the pipeline 10 on the outer walls of the two groups of pipe fitting locking assemblies 9, and then start the servo motor 907, which drives the driven gear 908, When the ring gear 906 and the turntable 903 rotate, when the convex surface of the hemispherical projection 904 rotates to the position of the rod 909, the rod 909 and the pressing block 910 will be pushed outwards, and the inner wall of the pipe 10 will be pressed against the inner wall of the pipe 10 to fix the pipe 10. The process can be adapted to multiple groups of pipes 10 with different diameters and lengths. After the fixing is completed, the motor 12 will be started, and the motor 12 will drive the gear 13, the transmission gear 11 and the rotating rod 7 to rotate, and then drive the pipe 10 to rotate slowly, which can avoid the outer wall of the pipe 10. The paint layer flows along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com