An in-pipe spraying device suitable for bent pipes

A technology of internal spraying and pipe bending, applied in the direction of spraying device, etc., can solve the problems of poor spraying effect, limited spraying distance, high labor intensity, etc., and achieve the effect of uniform spraying

Active Publication Date: 2022-06-03

河北方泉管道装备有限公司

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In order to improve the anti-rust ability of pipe fittings, it is necessary to spray paint on the inner and outer walls of pipe fittings. The common spraying method is manual spraying, which is too labor-intensive and requires a lot of labor, especially the effect of manual spraying on the inner wall of pipe fittings is poor. , the spraying distance is limited, and at the same time, it is impossible to spray on the bend of the pipe

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach 1

specific Embodiment approach 2

specific Embodiment approach 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

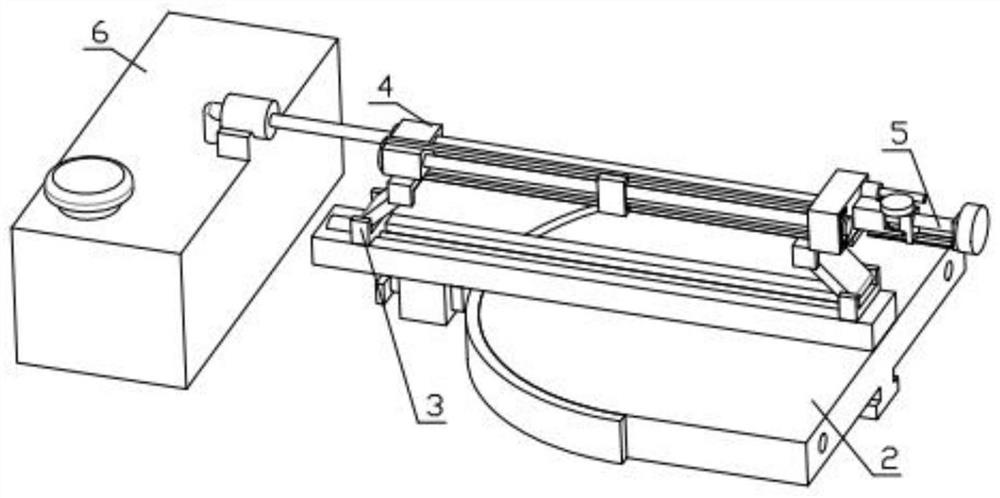

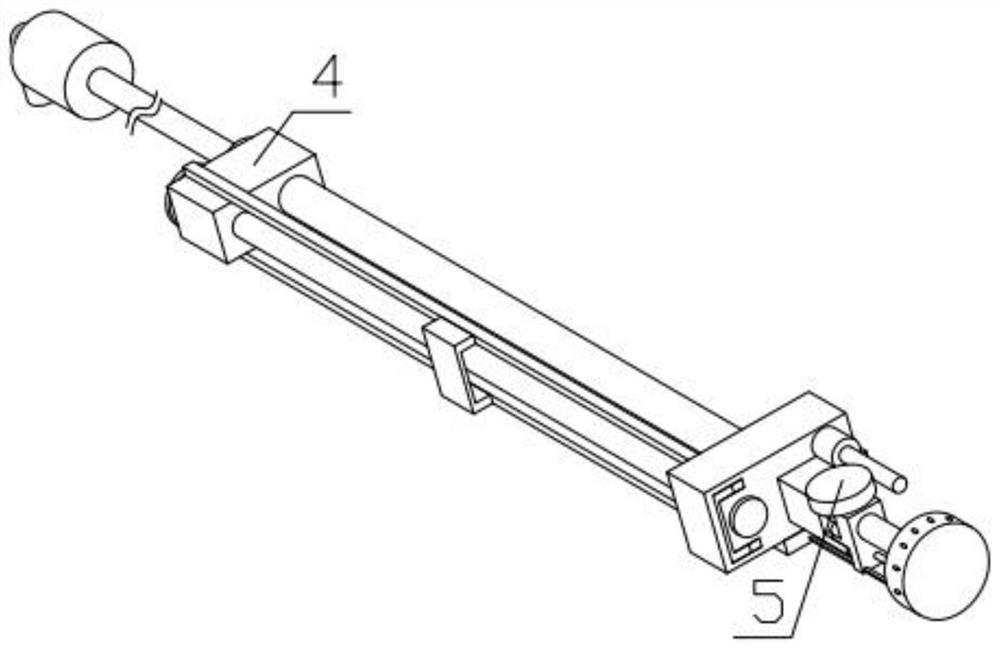

The present invention relates to the related field of building material processing, more specifically, it is an in-pipe spraying device suitable for curved pipes, including a distance adjustment mechanism, an angle adjustment mechanism, a height adjustment mechanism, a propulsion mechanism, an elbow mechanism and a material box. The angle adjustment mechanism is threadedly connected with the distance adjustment mechanism, the distance adjustment mechanism is fixedly equipped with a material box, the height adjustment mechanism is rotatably installed on the angle adjustment mechanism, the propulsion mechanism is fixedly installed on the height adjustment mechanism, and the elbow mechanism is fixedly installed on the propulsion mechanism. The elbow mechanism is fixedly connected with the material box; the device sprays in a rotating manner to avoid uneven spraying caused by blockage of individual nozzles. The device not only has the function of spraying straight pipes, but also has the function of spraying the bends of pipe fittings .

Description

An in-pipe spraying device suitable for curved pipes technical field [0001] The present invention relates to the related field of building materials processing, and more particularly to a pipe in-pipe spraying device suitable for curved pipes. Background technique In order to improve the anti-rust ability of pipe fittings, the inner and outer walls of pipe fittings need to be sprayed and treated, and common spraying methods are used. The method is to use manual spraying, which is too labor-intensive and requires a lot of labor, especially the manual work on the inner wall of the pipe fittings. The spraying effect is poor, the spraying distance is limited, and at the same time, it is impossible to spray the bend of the pipe. SUMMARY OF THE INVENTION The technical problem that the present invention mainly solves is to provide a kind of in-pipe spraying device that is applicable to bent pipe, and this device passes through Spraying is carried out in a rotating way to ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B05B13/06

CPCB05B13/0636Y02P70/10

Inventor 黄路民

Owner 河北方泉管道装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com