Strawberry hydroponic optimized planting system

A planting system and hydroponics technology, applied in cultivation, soilless cultivation, botanical equipment and methods, etc., can solve the problems of strawberry yield reduction, hypoxia stress, inability to optimize planting plans, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

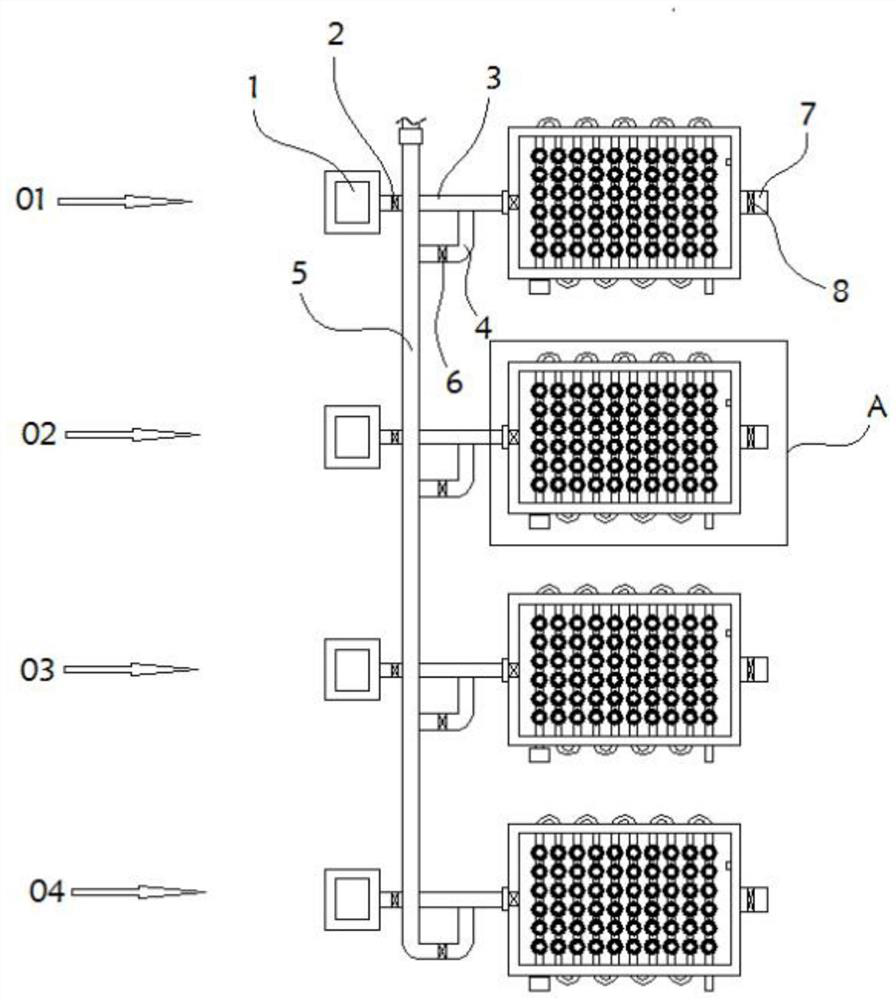

[0028] refer to figure 1 Shown:

[0029] A strawberry hydroponic optimized planting system, including a plurality of control planting groups, any control planting group includes a nutrient solution container 1, a nutrient solution outlet pipe 3, a first flow pump 2 arranged on the nutrient solution outlet pipe, The main water inlet pipe 5, the water adding pipe 4 connected between the water inlet main pipe 5 and the right part of the nutrient solution outlet pipe 3, the second flow pump 6 arranged on the water inlet pipe 4, and the right end of the nutrient solution outlet pipe 3 are connected The hydroponic pond 9, some strawberry hydroponic hole grooves 12 located in the hydroponic pond 9, and the oxygen supply mechanism located in the hydroponic pond, a plurality of control planting groups hydroponic strawberries according to different nutrient solution supply schemes, in The top of the hydroponic ponds of each control group is also provided with a camera 16, and the camer...

Embodiment 2

[0035] On the basis of Embodiment 1, this embodiment has made further improvements, specifically:

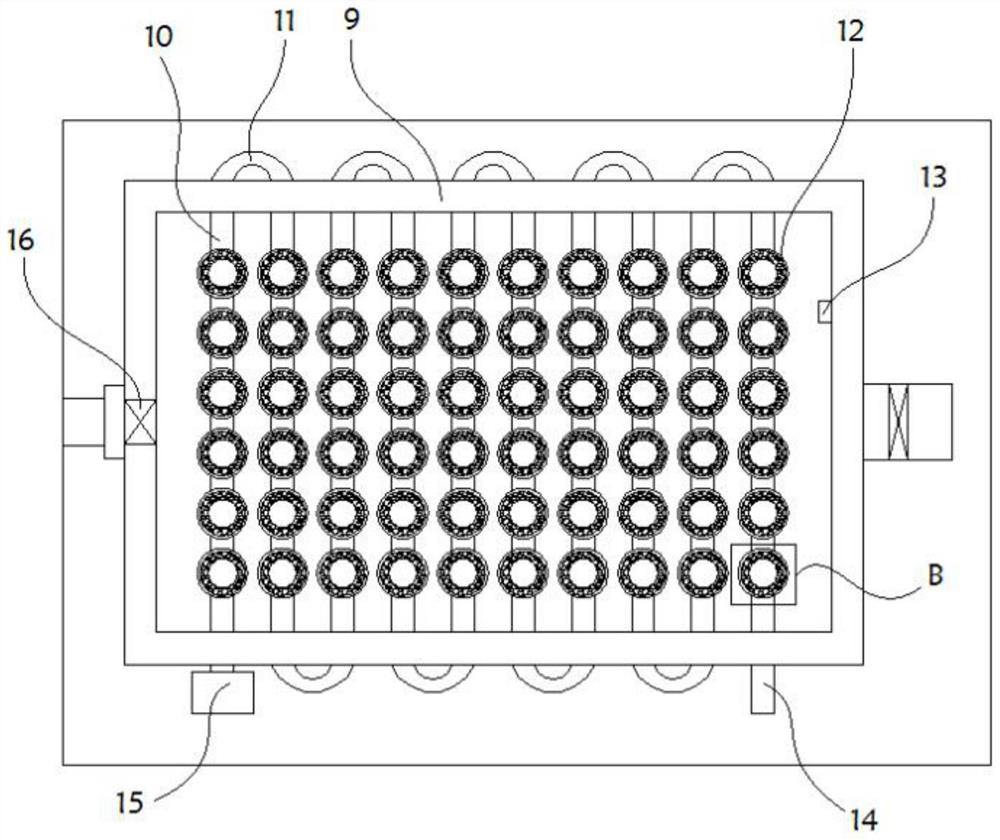

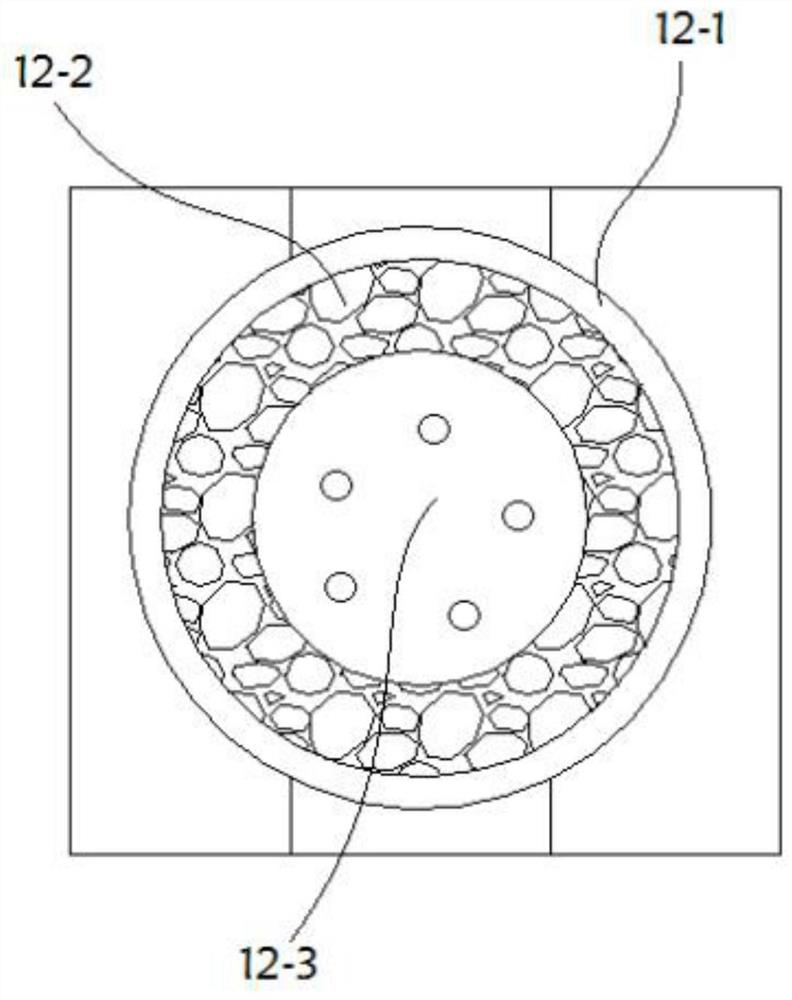

[0036] see figure 2 , 3 As shown, the outer wall or bottom of the strawberry hydroponic hole tank 12 is provided with a through hole, and communicates with the nutrient solution through the through hole, and an annular foam body is also provided on the inner surface of the outer wall 12-1 of the strawberry hydroponic hole tank 12-2, a strawberry hydroponic cavity 12-3 is formed inside the annular foam body 12-2, and the annular foam body 12-2 can float up and down in the strawberry hydroponic hole groove 12 under the buoyancy of the nutrient solution, and In the process of floating up and down, the nutrient solution in the strawberry hydroponic well tank 12 is squeezed and sucked, thereby promoting the exchange of nutrient solution inside and outside the strawberry hydroponic well tank 12 .

[0037] Because the nutrient solution in the strawberry hydroponic hole tank 12 lacks...

Embodiment 3

[0039] On the basis of Embodiment 2, this embodiment has made further improvements, specifically:

[0040] Such as Figure 4 , 5 As shown, the oxygen supply mechanism includes aquatic plants 18 planted at the bottom of the hydroponic tank 9, and the aquatic plants 18 can inhale carbon dioxide and exhale oxygen.

[0041] The type of aquatic plants and the amount of planting can still be compared in the manner of Example 1. When the best effect is obtained, it is the optimal plan for the type of aquatic plants and the amount of planting. Specifically, for example, the same nutrient solution, the same concentration, and different aquatic plants can be optimized by comparing and analyzing the growth of strawberries. After optimization, a variety of aquatic plants with better effects on strawberry growth can be obtained, and then further optimized, that is - the same species Aquatic plants and different planting quantities can also be optimized through comparative analysis, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com