Segmented cultivation pond for soilless cultivation

A technology of soilless cultivation and cultivation pool, applied in the direction of soilless cultivation, cultivation, botanical equipment and methods, etc., can solve the problems of inability to cultivate different kinds of flowers, waste of cultivation space, waste of manpower and material resources, etc., to achieve convenient calculation and Adjustable, not easy to confuse, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

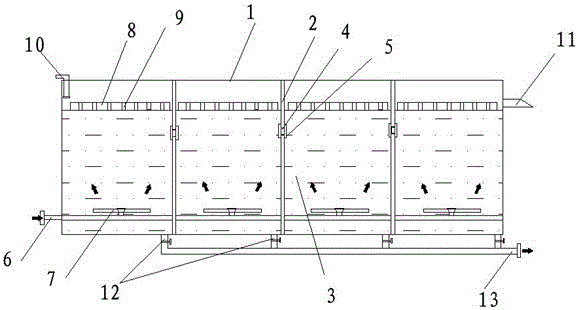

[0016] Example 1 : Such as figure 1 Shown is a segmented cultivation pond for soilless cultivation, the cultivation pond is a rectangular pond body 1, the middle part of the pond body 1 is provided with multiple vertically installed partition structures 2, and the partition structure 2 Divide the pool body 1 into a plurality of culture areas 3 with the same volume, and a culture solution communication port 4 is provided at the height of 3 / 5 of each partition structure 2, and the culture area 3 at the front end of the pool body 1 is provided with There is a liquid inlet 10, and the lower part of the pool body 1 is provided with a gas transmission pipeline 6, and the gas transmission pipeline 6 is provided with a circular gas outlet 7 heads in each culture area 3, each The cultivation area 3 is provided with a cultivation fixed plate 8 , and the bottom of each cultivation area 3 is respectively provided with a drain port 12 , and multiple drain ports 12 of the same cultivati...

Embodiment 2

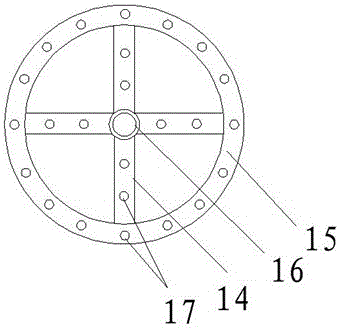

[0017] Example 2 : Such as figure 1 and 2 As shown, the circular air outlet head 7 of the present invention has a cross air outlet pipe 14 and a circular air outlet pipe 15, and the circular air outlet pipe 15 is fixedly welded on the circular air outlet head 7 through the cross air outlet pipe 14; A plurality of air outlet structures 17 are evenly distributed on the cross air outlet pipe 14 and the annular air outlet pipe 15 described in the invention, and the distance between two adjacent air outlet holes 17 is 6-8 cm.

[0018] Hydroponics is to immerse the plant roots in the nutrient solution to grow. This method will cause oxygen deficiency, which will affect the respiration of the roots and cause the death of the roots in severe cases. Therefore, in the process of hydroponics, in order to solve the problem of oxygen supply, it is necessary to use gas transmission Pipeline 6 feeds oxygen into the cultivation pond; but because the nutrient solution in the soilless cult...

Embodiment 3

[0019] Example 3 : Such as figure 1 and 2 As shown, the center of circle of the circular air outlet head 7 of the present invention and the cross point of the cross air outlet pipe 14 are provided with a press-fit switch 16, and the circular air outlet head 7 in each area is conveniently closed by the press-fit switch 16. The cultivating time may be different, in order to prevent the vacant cultivating region 3 from wasting oxygen, the oxygen supply in the cultivating region is closed in time by a press-fit switch 16 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com