Supplier reliability analysis system and analysis method

An analysis system and supplier's technology, applied in data processing applications, instruments, resources, etc., can solve problems such as judging and standardizing a large amount of information, and achieve the effects of improving production efficiency, improving comprehensiveness and objectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

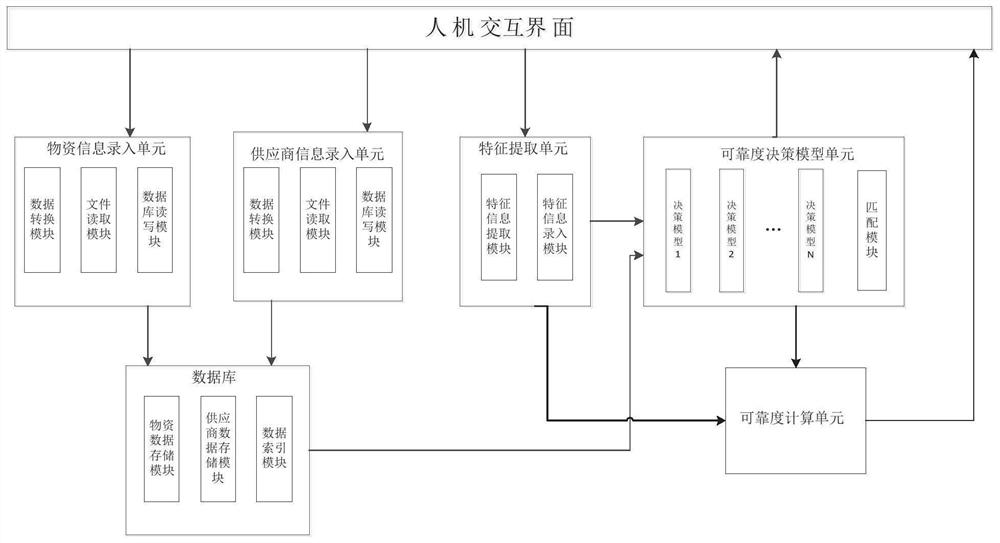

[0031] This embodiment provides a supplier reliability analysis system, its schematic diagram is as follows figure 1 As shown, it includes: human-computer interaction interface, material information input unit, supplier information input unit, database, feature extraction unit, reliability decision model unit, and reliability calculation unit.

[0032] The human-computer interaction interface is used for human-computer interaction. Users can perform corresponding supplier reliability analysis operations through the human-computer interaction interface. For example, users input supplier information and material information through the human-computer interaction interface, and search for corresponding supplier reliability.

[0033] The material information input unit is used to input material information, for example, the user inputs corresponding material information through the material information input unit displayed in the human-computer interaction interface.

[0034] The...

Embodiment 2

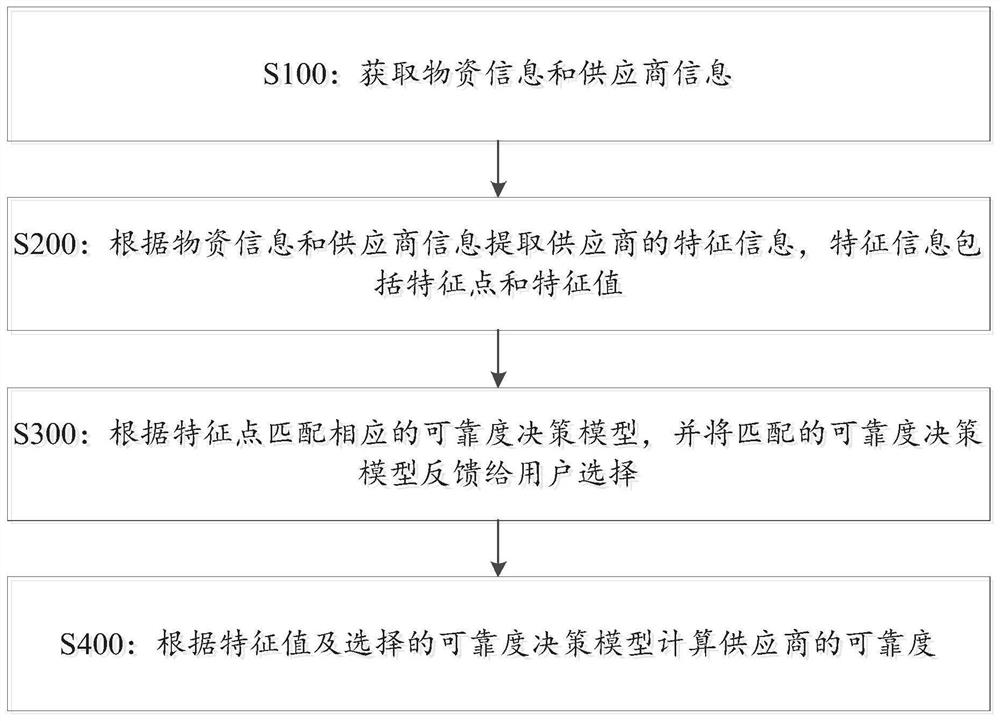

[0059] Based on Embodiment 1, this embodiment provides a supplier reliability analysis method, the flow chart of which is as follows figure 2 As shown, it specifically includes the following steps.

[0060] S100: Obtain material information and supplier information.

[0061] For example, obtain supplier information and material information through the human-computer interaction interface, specifically, initiate the acquisition of material information from an external database on each natural day according to the time set by the user, and convert the data into the format required for supplier reliability analysis After receiving the user request sent by the man-machine interface, the material information input unit reads the configuration file in the specified format uploaded by the user, and writes the data into the material data storage module. Similarly, in each natural day, according to the time set by the user, the supplier information is obtained from the external datab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com