Sliding bearing

A technology for sliding bearings and shields, which is applied in the direction of sliding contact bearings, bearings, and bearings for rotational motion, etc., can solve the problems of high integration, large additional space, and small size, and achieve high integration and reliability, power generation and The effect of strong power supply capacity and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

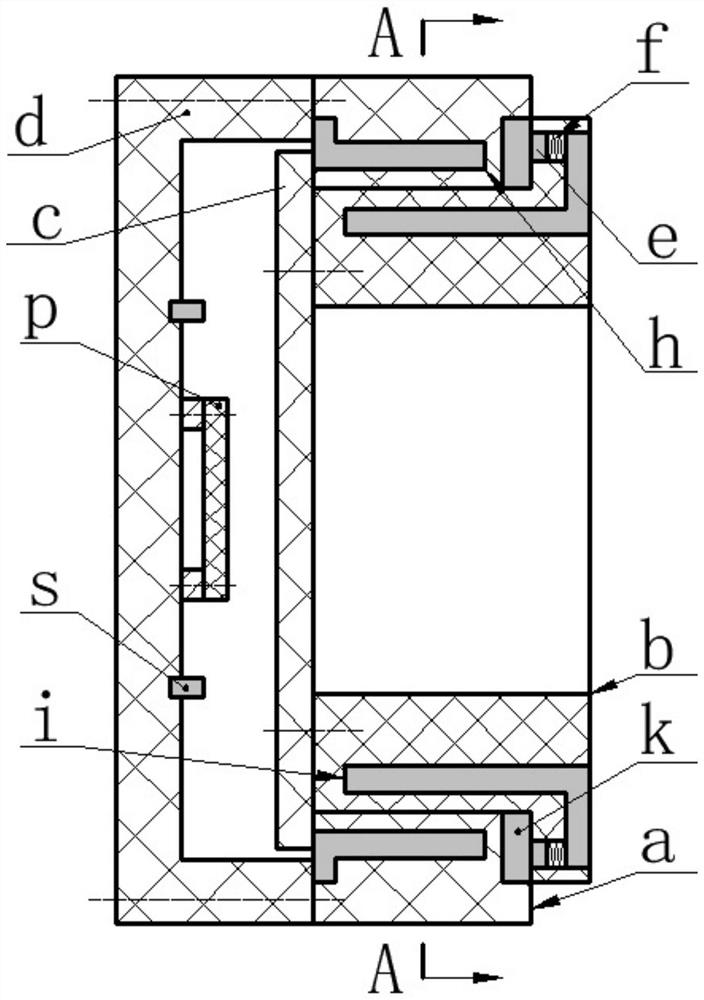

[0022] The present invention proposes a sliding bearing, which mainly includes an outer ring a, an inner ring b, a baffle c, a shield d, a sensor s and a circuit board p, and the circuit board p and the sensor s are installed inside the shield d, and the outer ring a Set on the inner ring b, one end of the inner ring b is provided with a retaining ring b2, the other end is installed with a baffle c through screws, the outer ring a is limited by the baffle c and retaining ring b1, and the shield d is installed on the outer ring through screws the end of a.

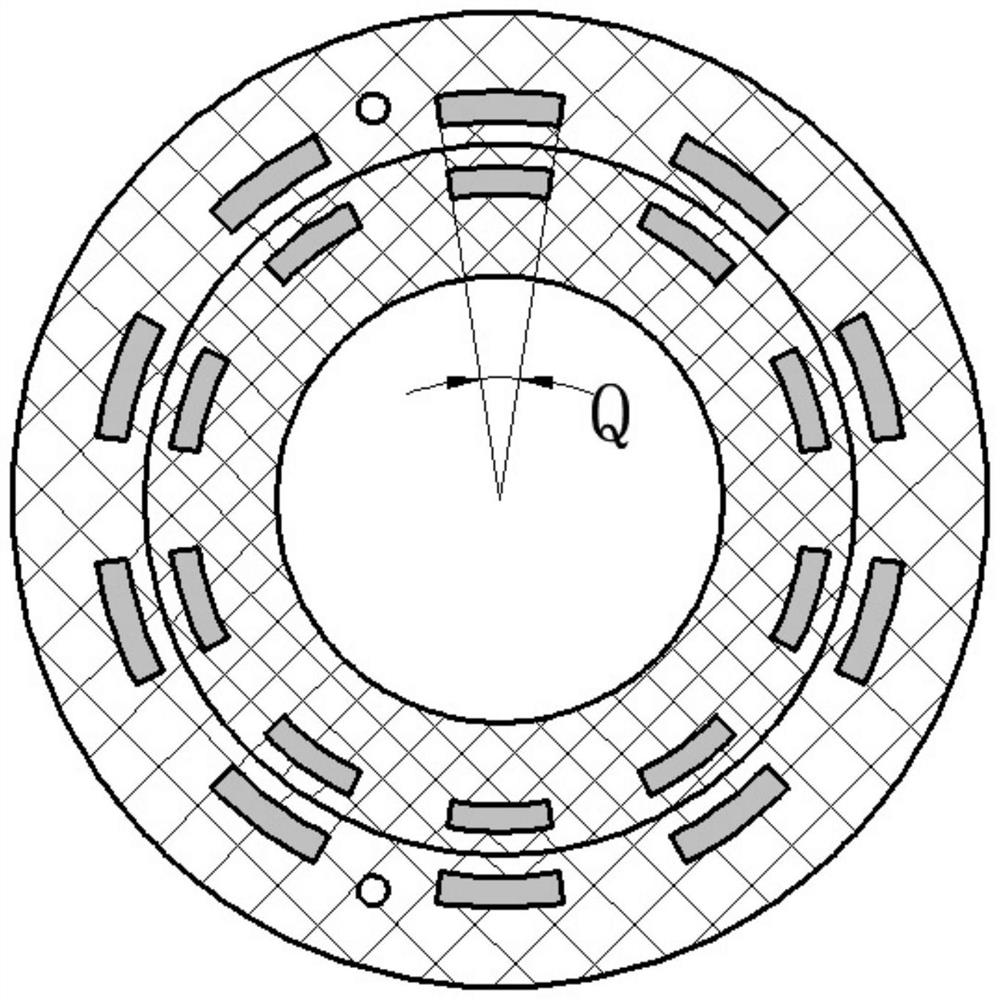

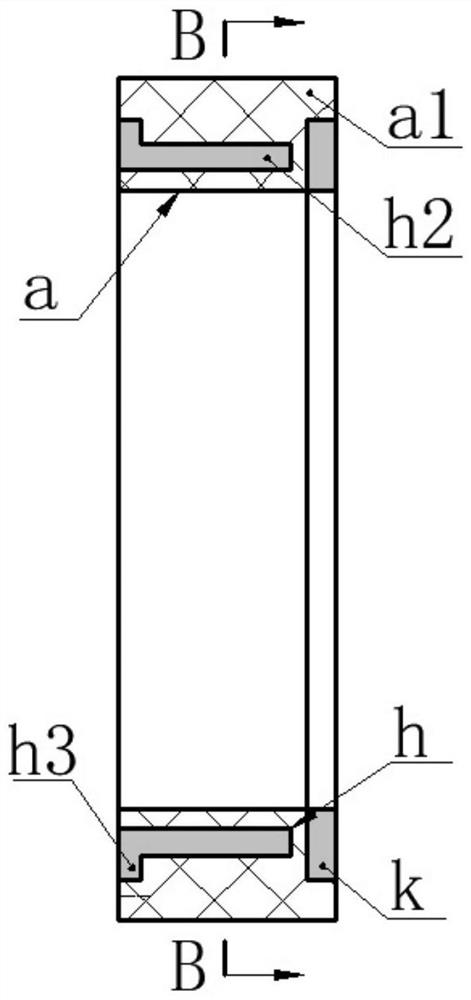

[0023] The outer ring a is composed of the outer ring body a1, the outer electrode h and the electrode ring k, the outer electrode h is composed of the outer pole ring h1, the outer pole finger h2 and the outer terminal h3, and the outer pole fingers h2 are evenly distributed on the right side of the outer pole ring h1 , the outer pole finger h2 is parallel to the axis of the outer pole ring h1, the outer terminal h3 is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com