Glass coating equipment with damage detection protection function

A technology of coating equipment and damage detection, applied in the direction of coating, etc., can solve the problems of dust being easy to follow and lead in, inconvenient, and poor dust-proof effect, so as to avoid dust follow-in and lead in, improve dust-proof effect, and increase anti-skid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

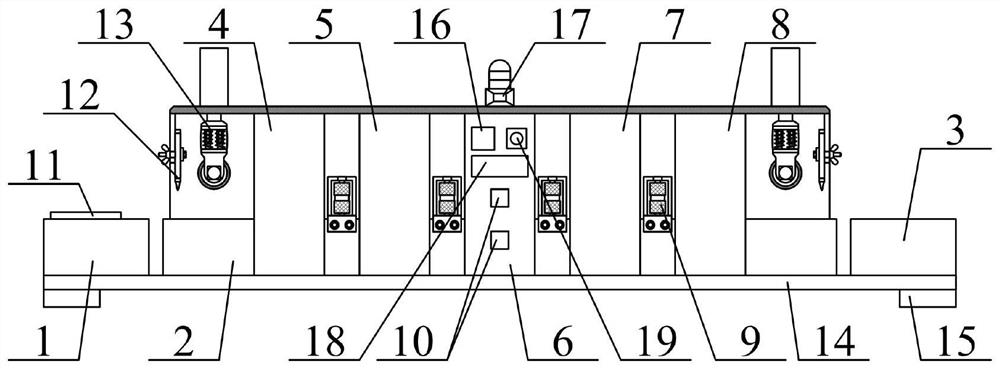

[0040] as attached figure 1 And attached image 3 shown

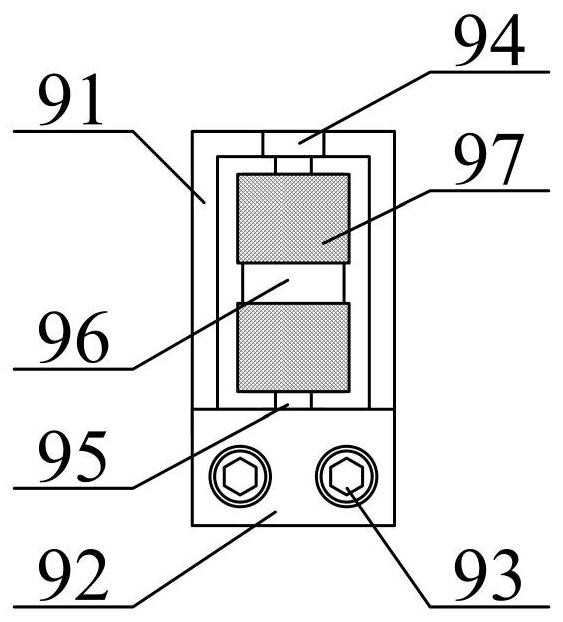

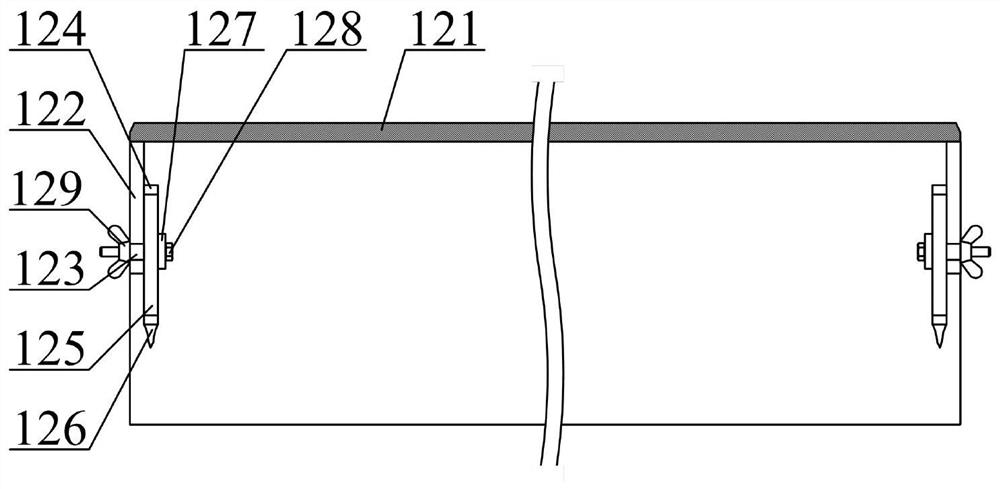

[0041] The invention provides a glass coating device with damage detection protection, comprising a feeding device 1, a transmission device 2, a feeding device 3, a left buffer transition chamber 4, a left buffer chamber 5, a coating chamber 6, and a right buffer chamber 7. Right side buffer transition chamber 8, side guide protective frame structure 9, detection device 10, glass substrate 11, adjustable protective frame structure 12, adjustable transmission frame structure 13, horizontal bottom plate 14, bottom leg 15, monitoring camera 16, sound and light alarm 17, control module 18 and power switch 19, the described feeding device 1, conveying device 2 and unloading device 3 are installed on the upper part of the transverse bottom plate 14 by bolts in turn; the left buffer transition chamber 4. The left buffer chamber 5, the coating chamber 6, the right buffer chamber 7 and the right buffer transition chamber 8 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com