Paint spraying equipment for automobile production

A technology for painting equipment and automobiles, which is applied in the direction of spraying devices, etc., can solve the problems that the painting device is difficult to apply to parts of different specifications, reduces work efficiency, cannot adjust the position and angle of parts, and achieves increased position and range. Convenience Painting work, avoid the effect of separation and peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

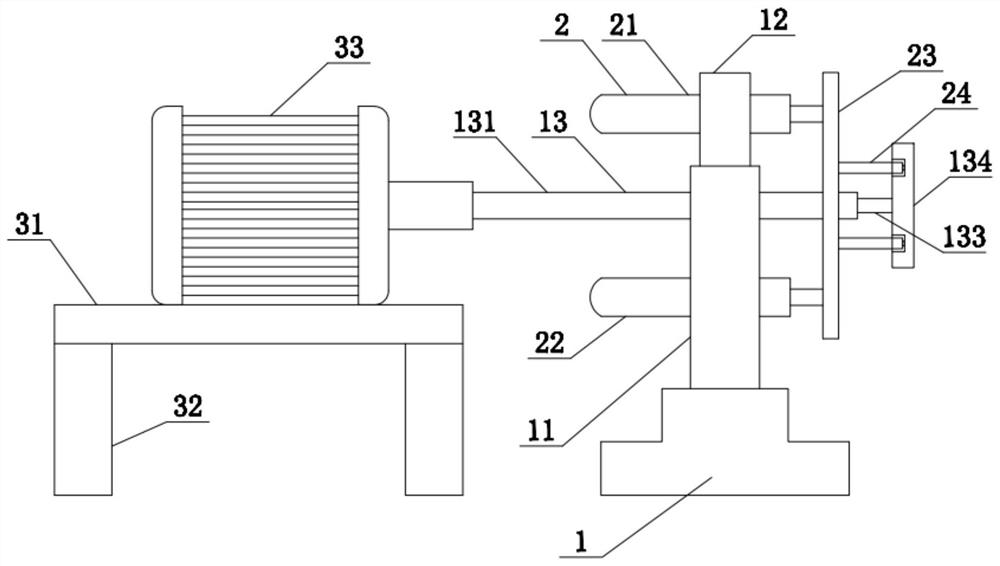

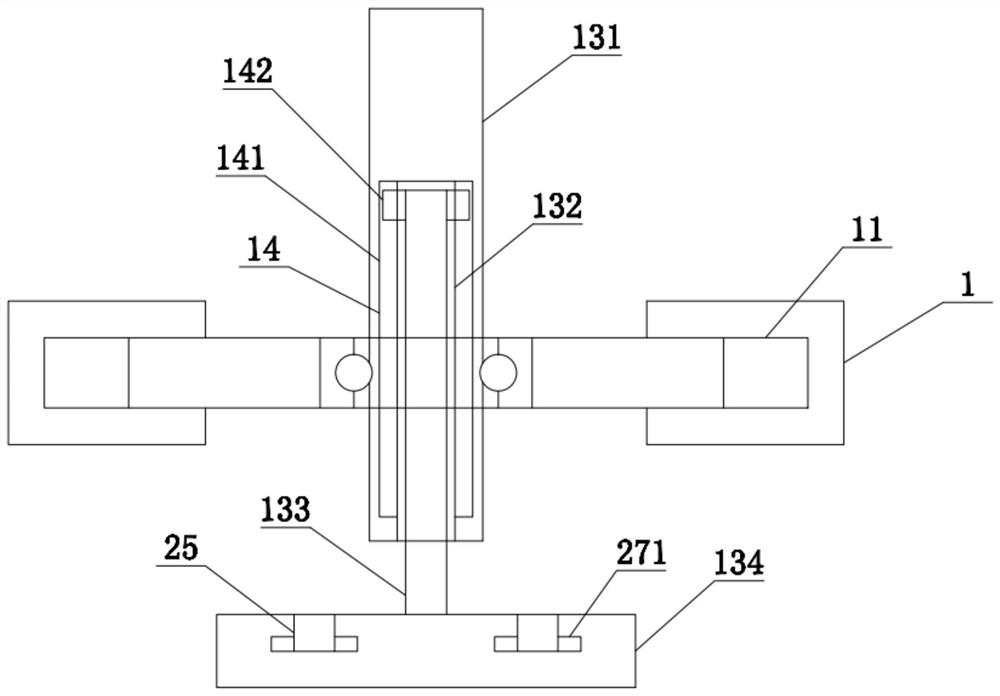

[0035]SeeFigure 1-5 A paint device for automobile production, including the first base 1 and the paint mechanism 4, and the upper end of the first base 1 is fixedly mounted, and the internal sliding connection of the bracket 11 has a clamping mechanism 13. The upper end of the bracket 11 is fixedly coupled with a first fixed block 12, and the internal fixation of the first fixed block 12 is fixedly mounted, and one end fixing lever of the clamping mechanism 13 is connected to the rotating assembly 3;

[0036]The paint mechanism 4 includes a second base 41, a column 42, a beam 43, a sliding assembly 44, a painting assembly 45 and a moving assembly 46, and the second base 41 is fixedly mounted on the left side of the first base 1, the column 42 is fixedly mounted on the upper surface of the second base 41, the beam 43 is fixedly mounted on the outer wall of the column 42, the sliding assembly 44 fixedly mounted inside the beam 43, the painting assembly 45 slides to be connected to the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com