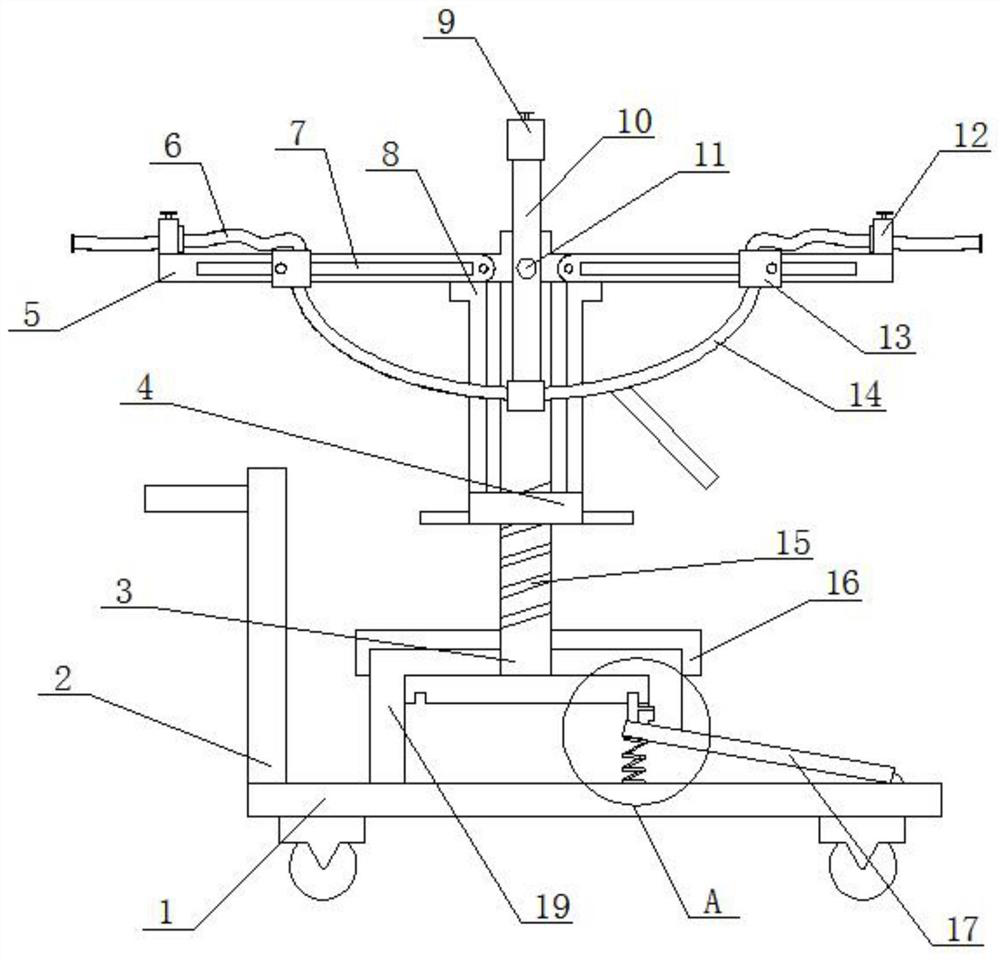

A high-efficiency spray dust suppression device for construction engineering

A technology for construction engineering and dust suppression devices, which is applied in spraying devices, liquid spraying devices, buildings, etc., can solve the problems of easy formation of dust, multiple spaces, and poor dust suppression effect, and achieve reduced occupied space, convenient storage and placement, and improved efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

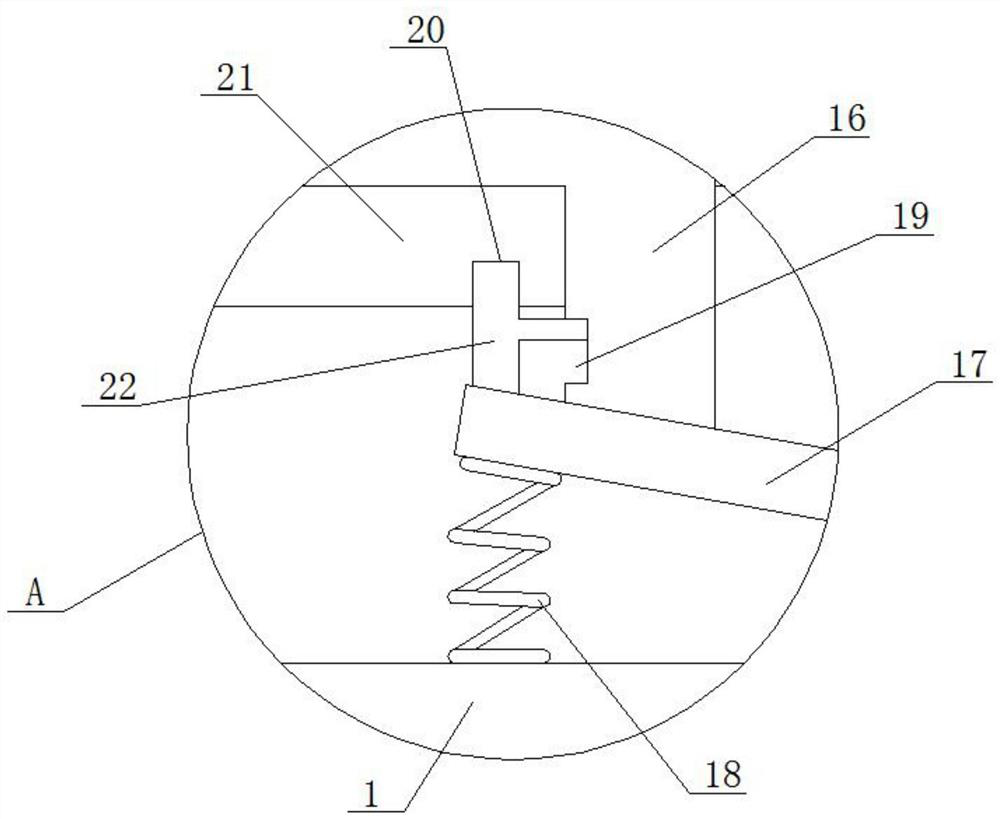

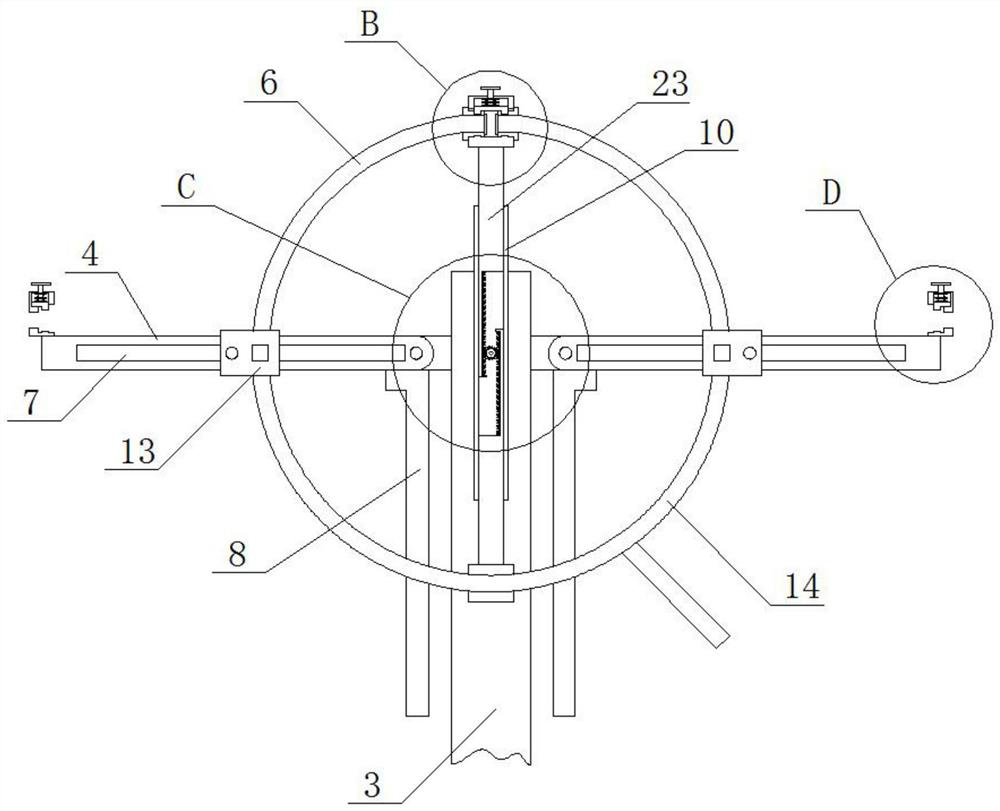

[0032]As a preferred embodiment of the present invention, the top of the inner side of the lower fixed block 12 is movably installed with an L-shaped clamping plate 30, and the top of the L-shaped clamping plate 30 is provided with an operating rod 24, on which the operating rod 25 An operating rod spring 25 is installed to facilitate fixing one end of the upper water pipe 6 and adjust the spraying area of the device.

[0033] As a preferred embodiment of the present invention, the shape of the telescopic plate 23 is "L", which is convenient for the gear 29 to drive the rack 31 to drive the telescopic plate 23 up and down.

[0034] As a preferred embodiment of the present invention, a clamping plate 26 is movably installed inside the upper fixed block 9 on the top, and an operating rod 24 is fixedly installed on the top of the clamping plate 26, and an operating rod is installed on the operating rod 24. The spring 25 can fix one end of the upper water pipe 6 and adjust the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com