Oblique adjustable supporting and reinforcing method for cantilever structure

A technology of oblique support and adjustment of support rods, which is applied to building construction, on-site preparation of building components, formwork/formwork/work frames, etc., can solve problems such as broken internal and external corners, poor concrete appearance quality, etc., to achieve The steps are simple, easy to promote and use, and the effect of strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] like Figure 1 to Figure 6 As shown, a method for reinforcing obliquely adjustable supports of a cantilevered structure of the present invention comprises the following steps:

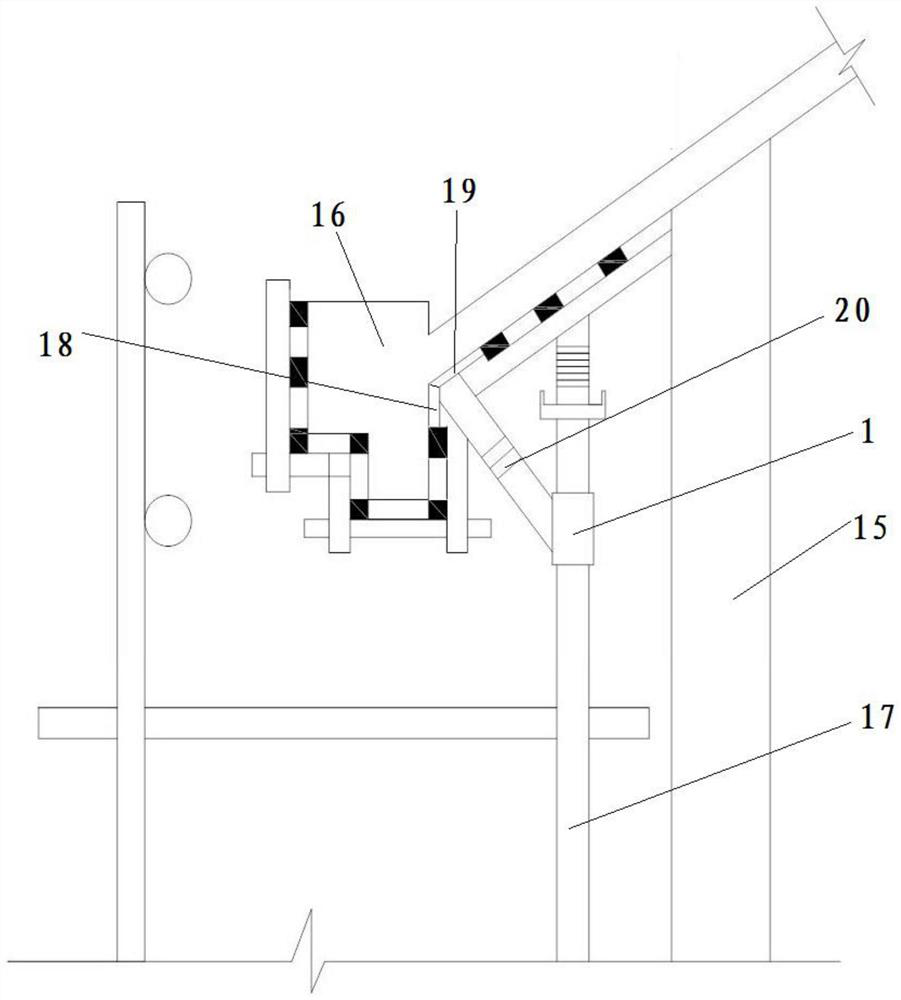

[0050] Step 1. Determine the adjustable support reinforcement structure: use the adjustable support reinforcement structure to perform oblique adjustable support on the male or female corners of the cantilevered structure 16 on the outside of the building's external wall 15;

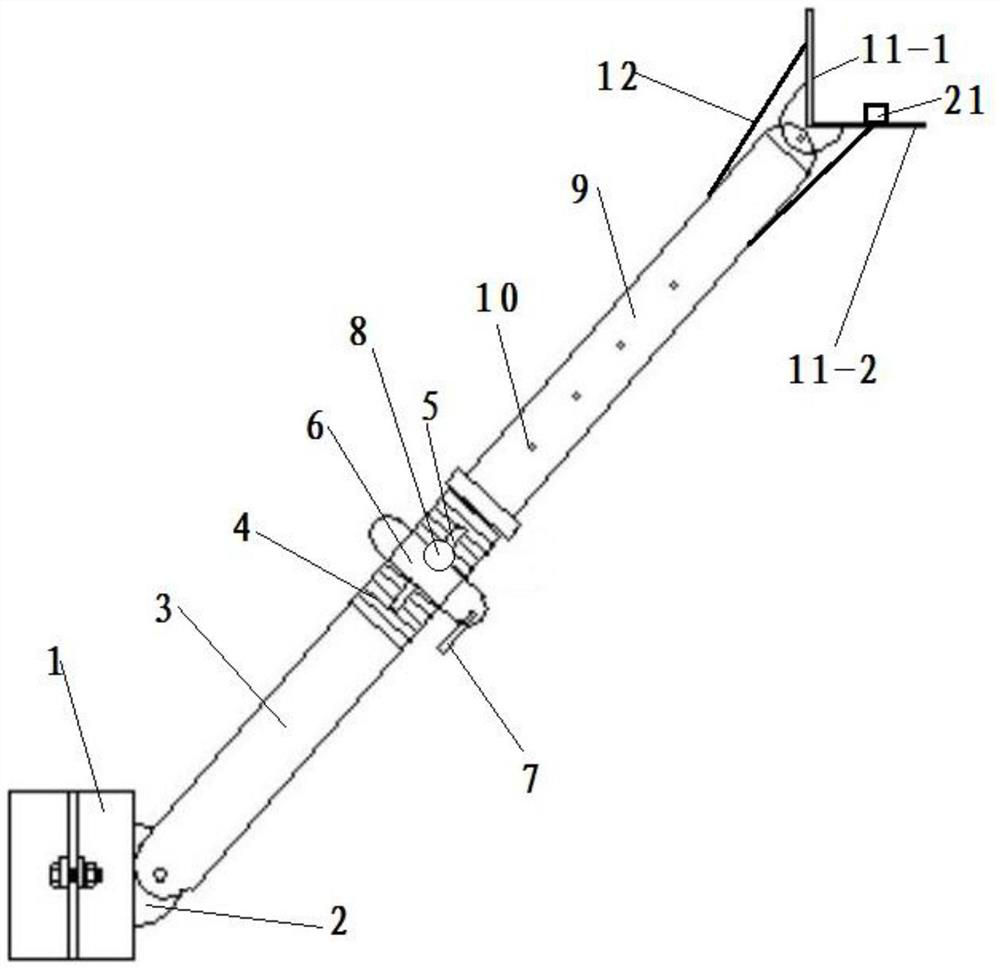

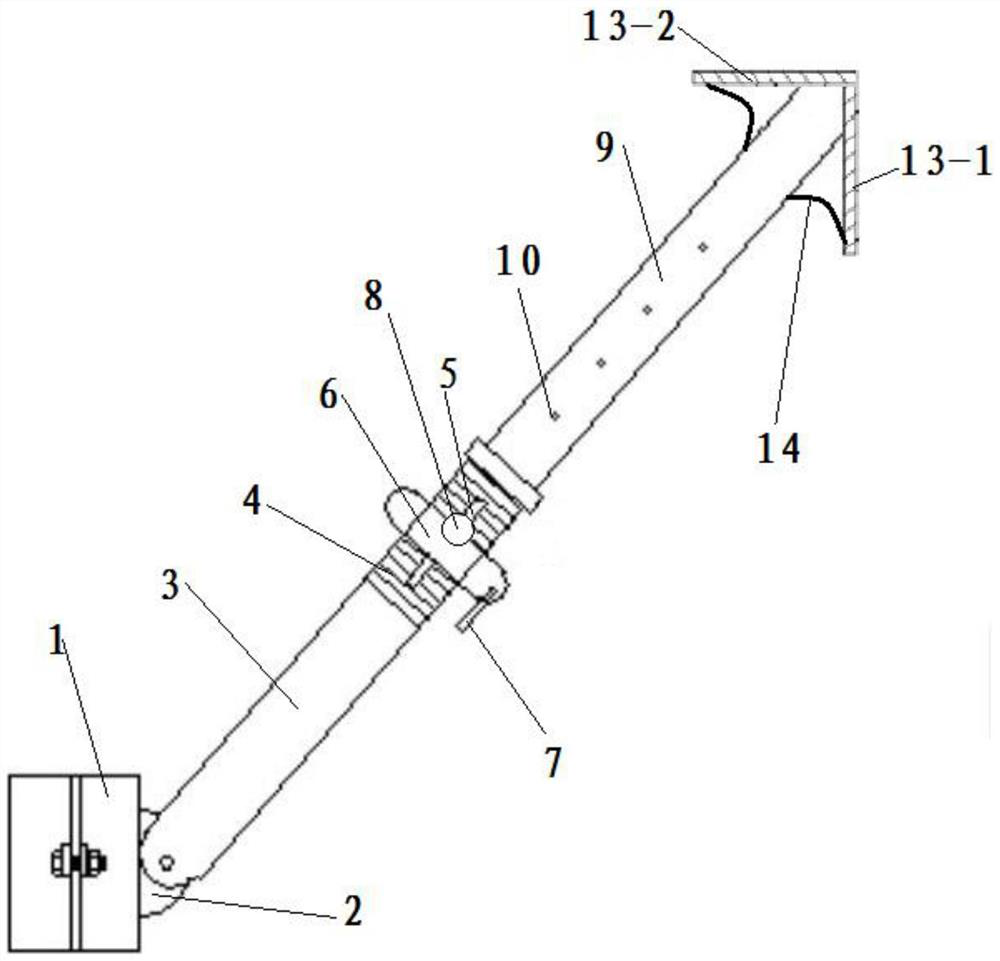

[0051] The adjustable support reinforcement structure includes a hoop 1 installed on a scaffold pole 17 between the building exterior wall 15 and the cantilever structure 16, and an adjustable support rod 20 hinged to the hoop 1 to adjust the support The end of the rod 20 away from the hoop 1 is fixedly provided with a vertical shaping plate 18 and a non-vertical shaping plate 19 that cooperate with the male or female corner of the cantilever structure 16;

[0052] The adjustment support rod 20 includes an outer tube 3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com