A steel structure node member

A steel structure and node technology, applied in the direction of building structure, construction, etc., can solve the problems of time-consuming, inconvenient disassembly and assembly of steel structures, and affecting the overall construction efficiency of on-site construction. The process is convenient and fast, and the installation process is convenient and fast , The effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following is attached Figure 1-6 The application is described in further detail.

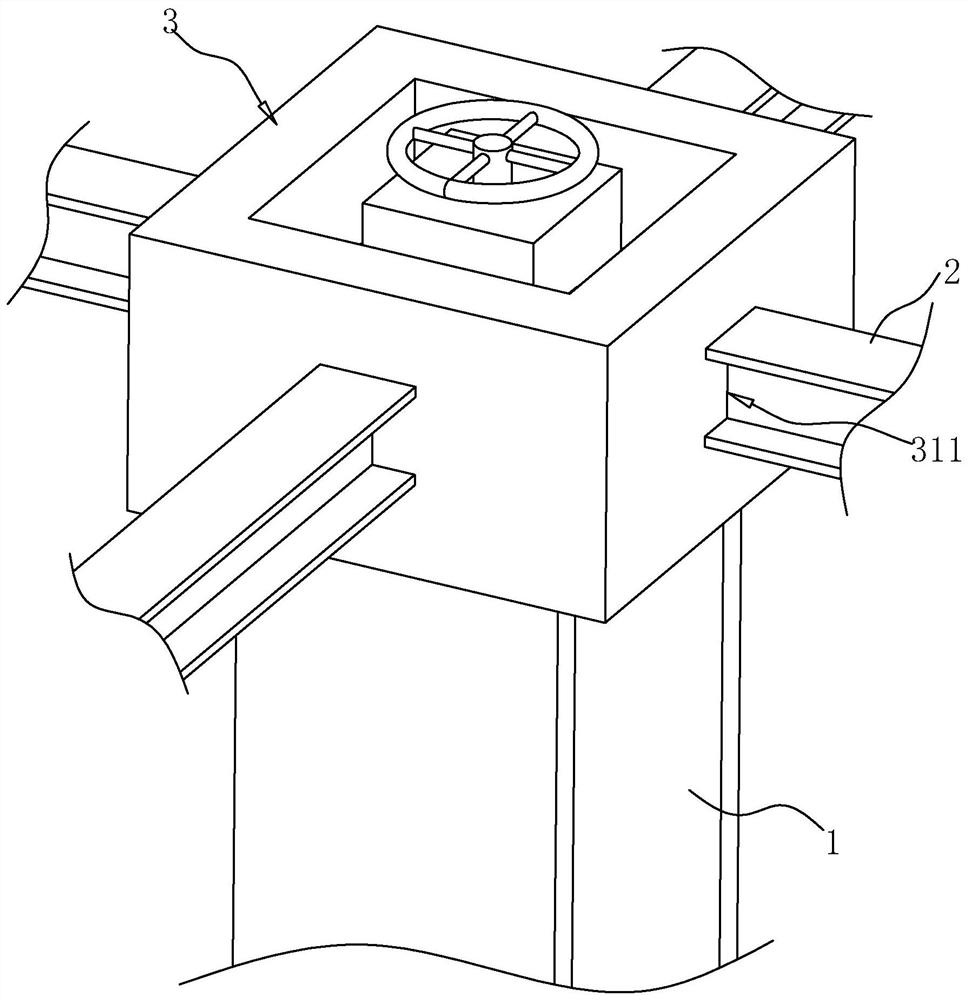

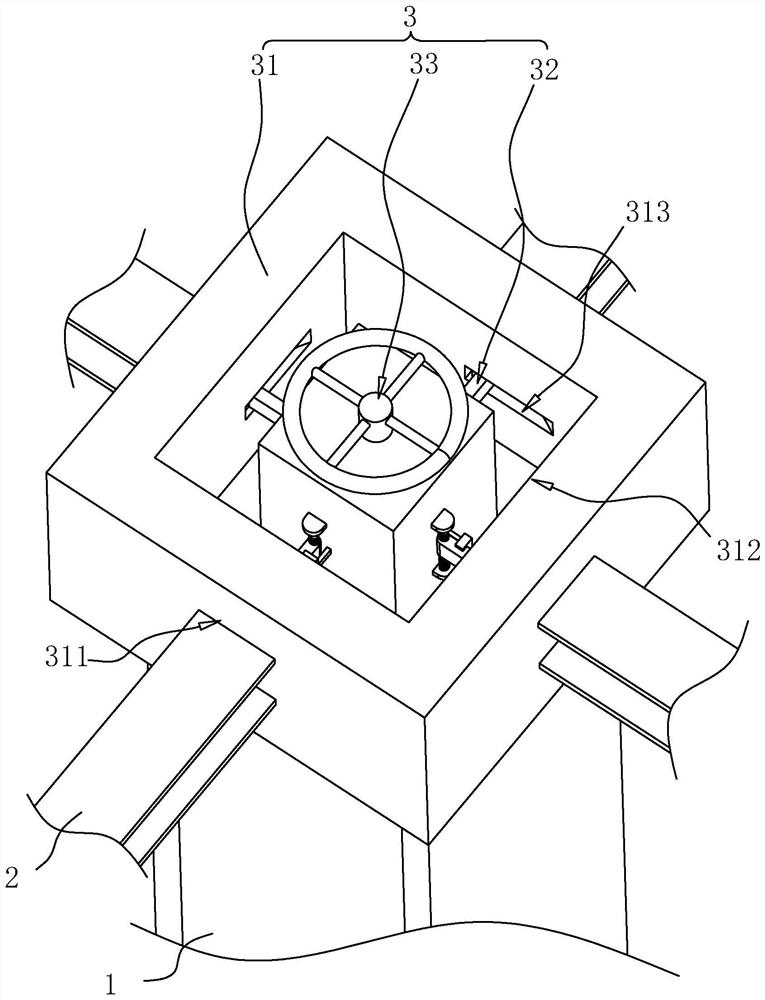

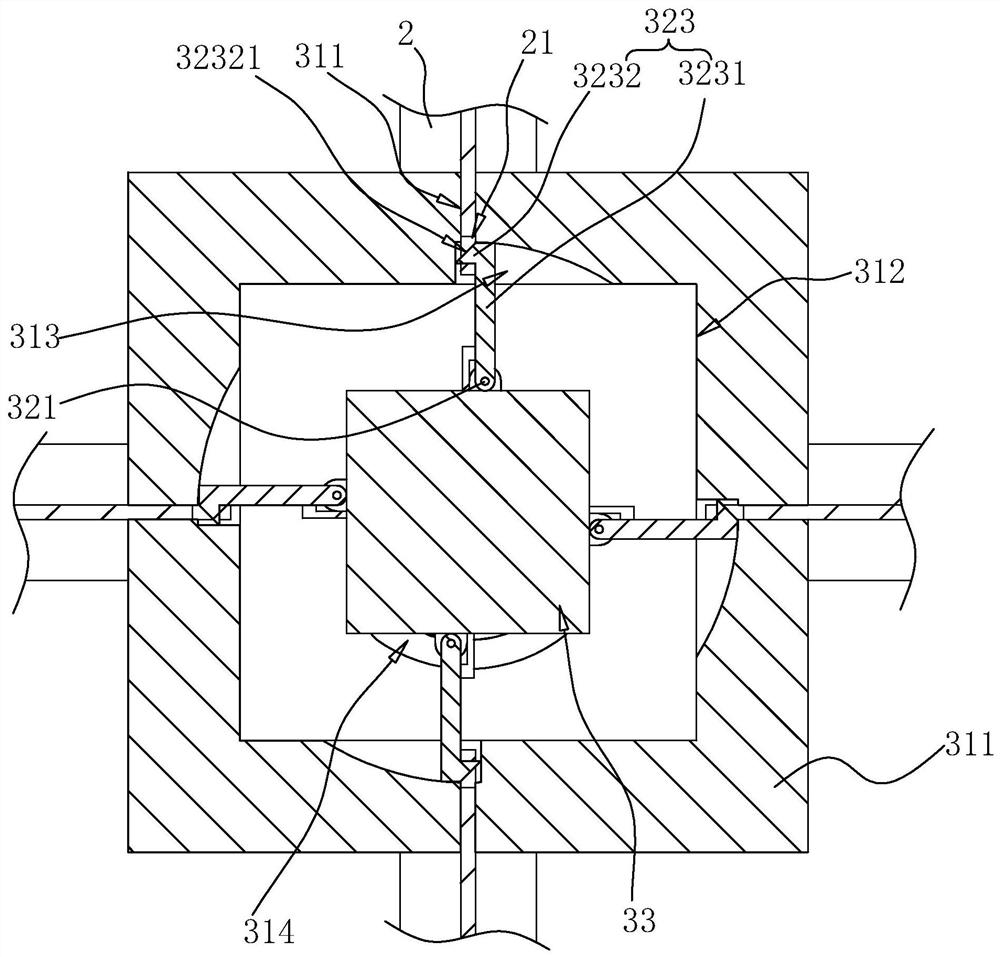

[0037] The embodiment of the present application discloses a steel structure node component. refer to figure 1 , the node component includes a steel column 1 and a steel beam 2, wherein the steel column 1 and the steel beam 2 are set in the form of I-shaped steel, the steel column 1 is placed along the vertical direction, and the bottom of the steel column 1 is fixedly installed on the ground, The steel beam 2 is used for fixed installation with the steel column 1, and the steel column 1 and the steel beam 2 can be built to form a three-dimensional support for carrying the building.

[0038] refer to figure 1 and figure 2 , in order to lift the steel column 1 and the steel beam 2 to be disassembled and assembled, the node construction also includes a node assembly 3, wherein the node assembly 3 includes a plug-in positioning part 31, an elastic buckle part 32 and an unlocking pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com