Organic biological ventilation fermentation compound fertilizer equipment

A technology of ventilation fermentation and organic biology, which is applied in the directions of organic fertilizer equipment, preparation of organic fertilizer, organic fertilizer, etc., to achieve the effect of improving fermentation effect and preventing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

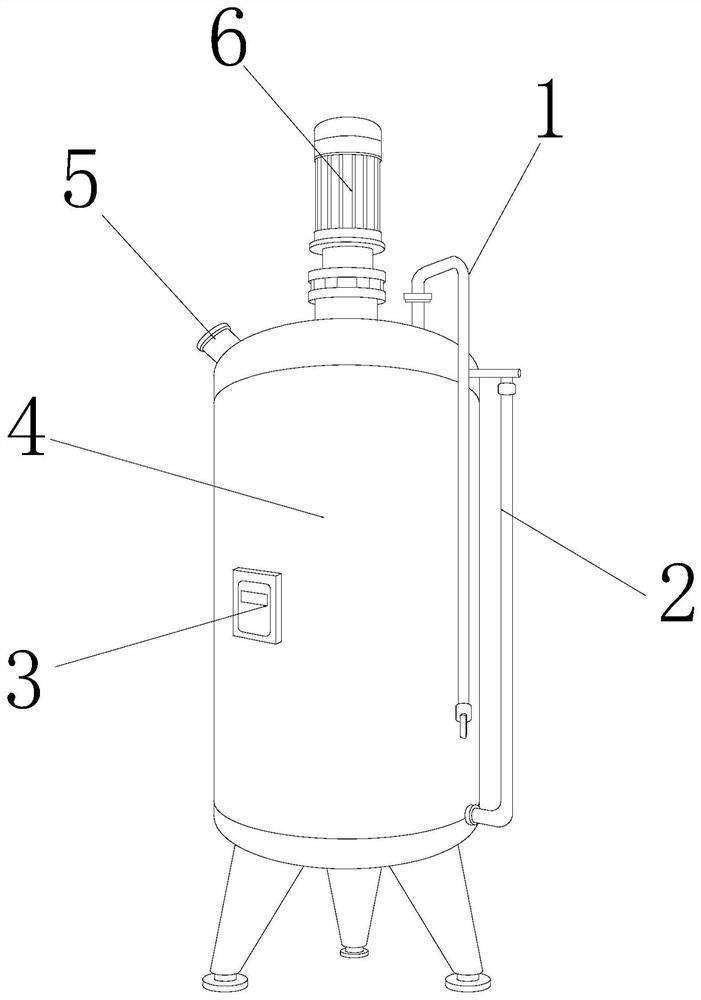

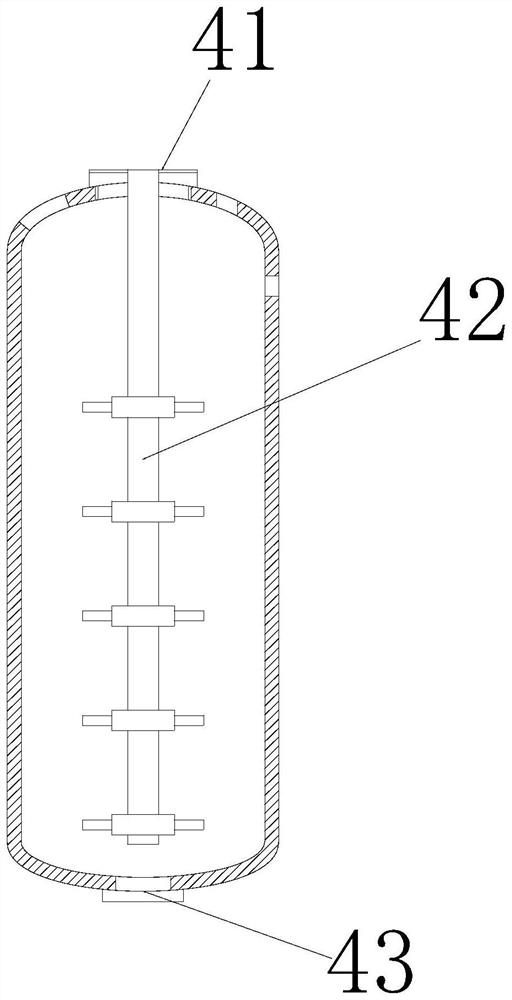

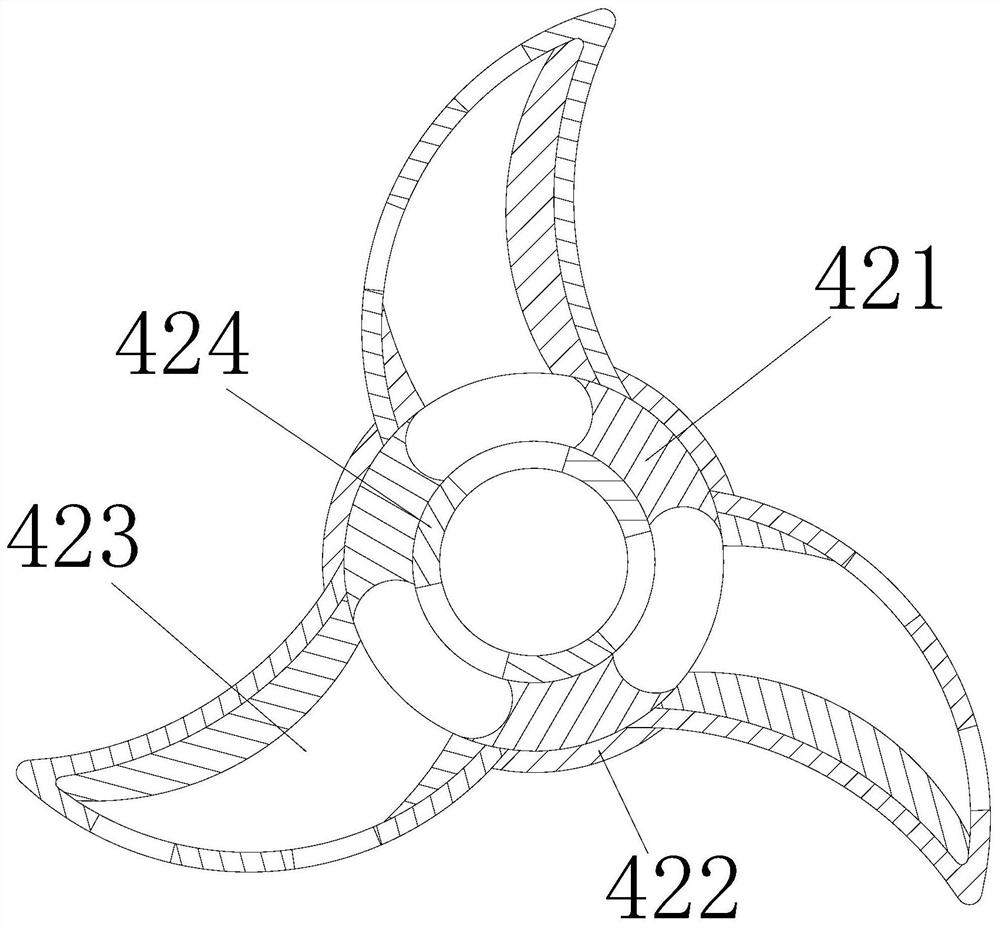

[0029] as attached figure 1 To attach Figure 4 Shown:

[0030] The invention provides a kind of equipment for organic biological ventilation and fermentation of compound fertilizer. The upper end of the body 4 is flange-connected, the left end of the water inlet pipe 2 is flange-connected to the right end of the body 4, the inner side of the temperature device 3 is installed on the outer side of the body 4, and the lower end of the feed port 5 is embedded and connected to the upper end of the body 4 The lower end of the motor 6 is engaged and connected to the upper end of the fuselage 4. The fuselage 4 includes a fermentation material port 41, a stirring mechanism 42, and a discharge port 43. The inner side of the fermentation material port 41 is embedded with the upper side of the stirring mechanism 42. connection, the upper end of the stirring mechanism 42 is engaged with the lower end of the motor 6 , and the upper end of the discharge port 43 is flange-connected with t...

Embodiment 2

[0036] as attached Figure 5 To attach Figure 8 Shown:

[0037] The present invention provides a device for organic biological ventilation and fermentation of compound fertilizer. The material guide block 232 includes a first chute 321, a moving mechanism 322, and a rebound block 323. The first chute is arranged inside the material guide block 232. 321, the inner side of the moving mechanism 322 is movably engaged with the first chute 321, the outer side of the moving mechanism 322 is engaged and connected to the outer side of the material guide block 232, and the inner side of the material guide block 232 is provided with a rebound block 323, the The first chute 321 is in the shape of a quarter arc, which enables the moving mechanism 322 to be attached to the outer wall of the material guide block. The resilient block 323 is made of silica gel, which increases the resilience of the resilient block 323 .

[0038] Wherein, the moving mechanism 322 includes a cleaning block 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com