Micro-plastic separation and recovery device and using method thereof

A technology for separation and recovery of microplastics, which is applied in the direction of plastic recycling and recycling technology, etc. It can solve problems such as uneven joints of the device, long separation process time, and easy adhesion of microplastics, so as to save time, make the device simple and convenient, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

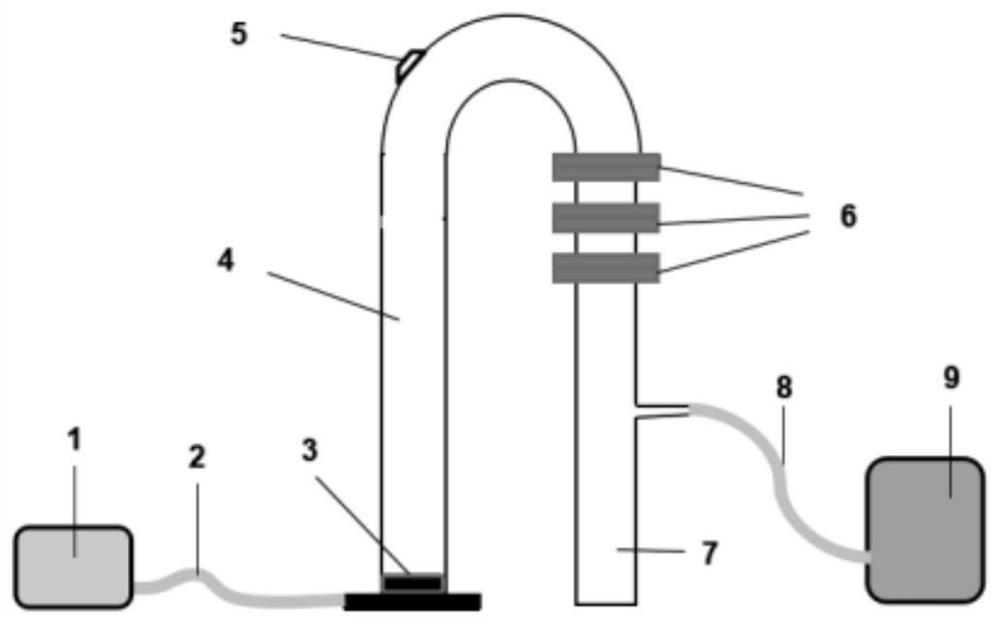

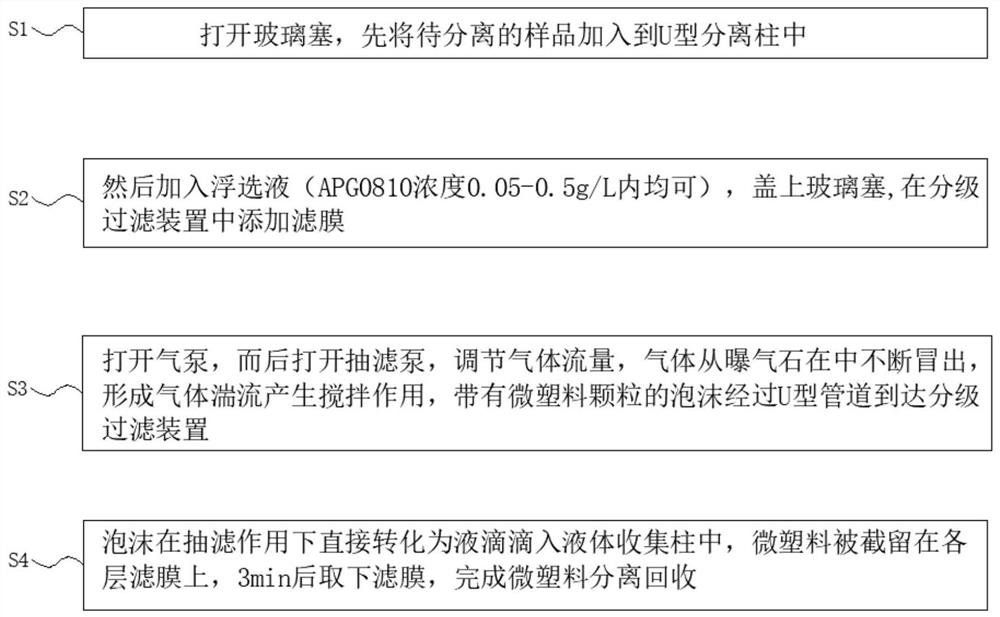

[0028]100 5 mm PVC, PET, PS, PE, and PP plastic are well mixed with 5 g of sand, simulate deposit samples; open the glass plug 5, first add the sample to be isolated into the U-shaped separation column 4, then join Different concentrations of APG0810 flotation solution, cover glass plug 5; add 0.45 μm aperture filter in the hierarchical filter device 6; open the gas pump 1, and then open the filtration pump 9, the regulated gas flow is 200 ml / min, the gas from aeration Stone 3 is constantly incurred, forming a gas turbulence to produce a stirring effect, and the foam with microcapstine particles passes through the U-shaped pipe 6, and the foam is directly converted into droplets under liquid collection column 7 The microchang is trapped on the filter membrane. Experiment found that when the APG0810 concentration is 0.05 g / L, the amount of foam is sufficiently supported to complete the microcapstine collection. When the APG0810 concentration reaches 0.5 g / L, the 5mm microcapsti...

Embodiment 2

[0030]100 3 mm PVC, PET, PS, PE and PP plastic are well mixed with 5 g of sand, simulate sediment samples; open the glass plug 5, first add the sample to be isolated into the U-shaped separation post 4, then join Different concentrations of APG0810 flotation solution, cover glass plug 5; add 0.45 μm aperture filter in the hierarchical filter device 6; open the gas pump 1, and then open the filtration pump 9, the regulated gas flow is 200 ml / min, the gas from aeration Stone 3 is constantly incurred, forming a gas turbulence to produce a stirring effect, and the foam with microcapstine particles passes through the U-shaped pipe 6, and the foam is directly converted into droplets under liquid collection column 7 The microchang was trapped on the filter membrane. Experiment found that when the APG0810 concentration was 0.05 g / l, the amount of foam was sufficiently supported to complete the microcapstine collection. When the APG0810 concentration reached 0.7 g / L, 3 mm microcapstine...

Embodiment 3

[0032]100 500 μm PVC, PET, PS, PE, and PP plastic are well mixed with 5 g of sand, simulate sediment samples; open the glass plug 5, first add the sample to be isolated into the U-shaped separation column 4, then add Different concentrations of APG0810 flotation solution, cover glass plug 5; add 0.45 μm aperture filter in the hierarchical filter device 6; open the gas pump 1, and then open the filtration pump 9, the regulated gas flow is 200 ml / min, the gas from aeration Stone 3 is constantly incurred, forming a gas turbulence to produce a stirring effect, and the foam with microcapstine particles passes through the U-shaped pipe 6, and the foam is directly converted into droplets under liquid collection column 7 The microchang was trapped on the filter, and the experiment found that when the APG0810 concentration was 0.05 g / l, the amount of foam was sufficiently supported to complete the microcapstine collection. When the APG0810 concentration reached 0.9 g / L, 500 μM microcap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com