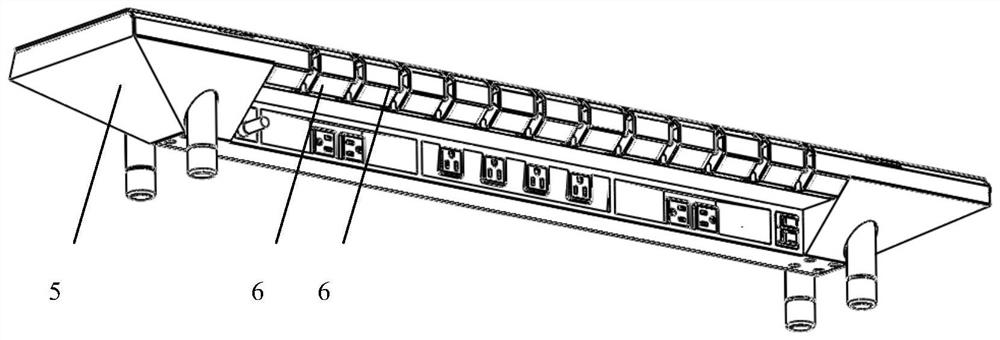

Wire harness collator and workbench

A beam organizer and workbench technology, applied to workbenches, manufacturing tools, etc., can solve problems such as difficulty in meeting usage requirements and inability to adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

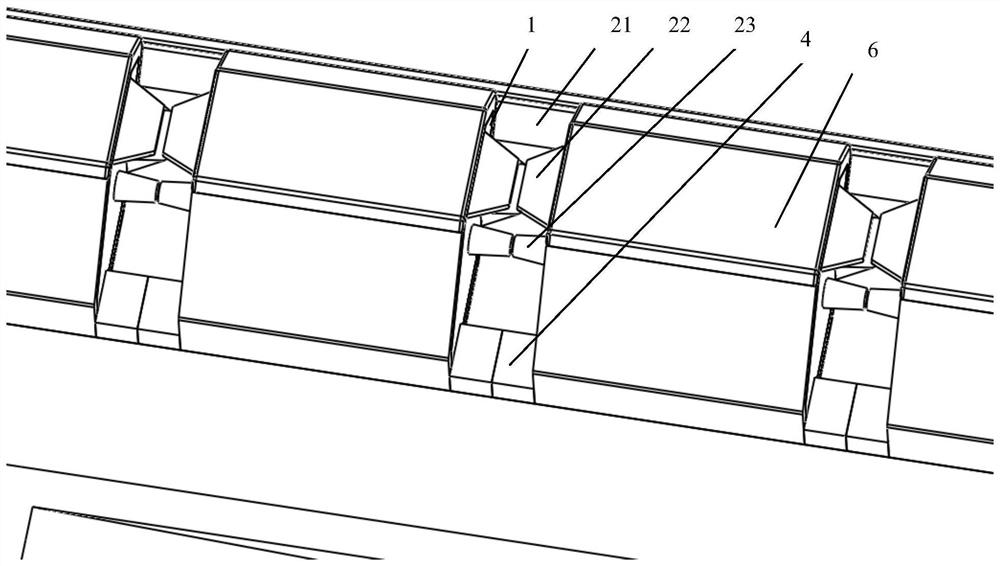

[0082] In a further embodiment of the present invention, the above-mentioned openings include: a first opening 31 located on one side of the accommodating space, a second opening 32 located on the lower side of the other side of the accommodating space, and a second opening 32 located on the lower side of the accommodating space. The third opening 33 on the upper side of the other side.

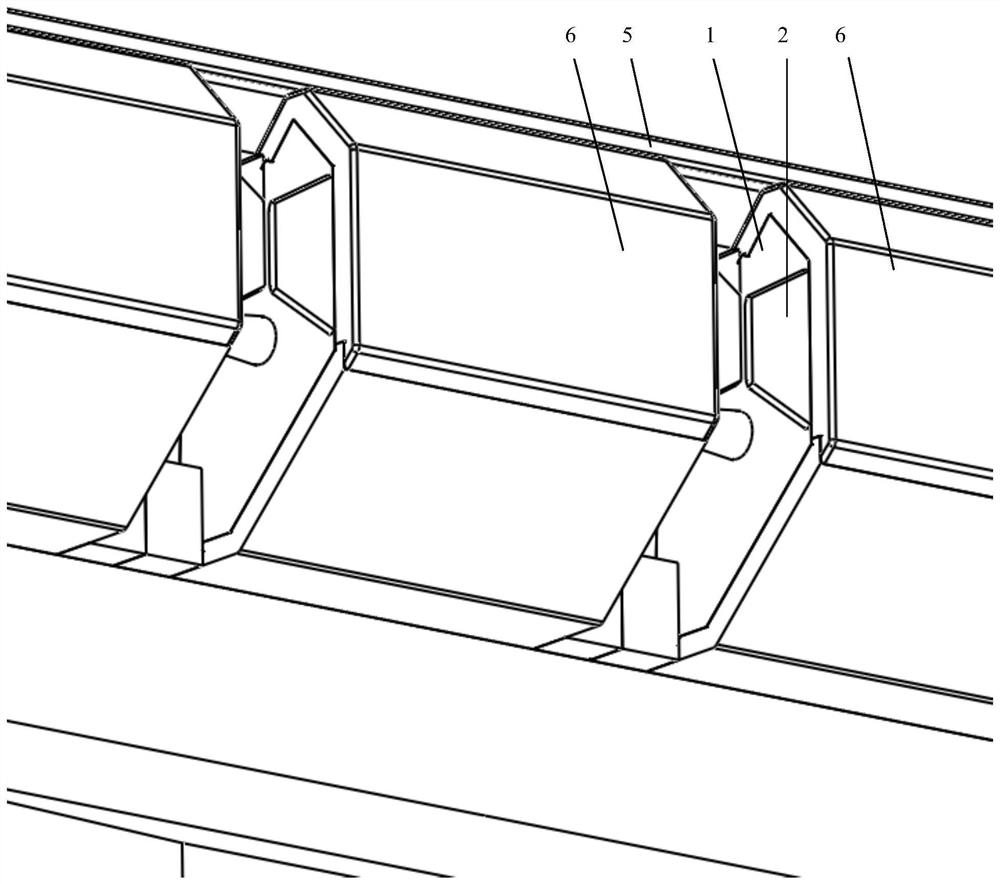

[0083] In a further embodiment of the present invention, the limiting structure 2 includes: two opposite first plate-shaped limiting structures 21 , and the two first plate-shaped limiting structures 21 are both located at the upper end of the plate-like structure 1 .

[0084] In a further embodiment of the present invention, the position-limiting structure 2 includes: two second plate-shaped position-limiting structures 22 oppositely arranged, and the two second plate-shaped position-limiting structures 22 are located on the other side of the plate-shaped structure 1 .

[0085] In a further ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com