Intelligent wind pressure control method for positive pressure dustproof system of hydraulic cone crusher

A technology of cone crusher and wind pressure, which is applied in the direction of grain processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

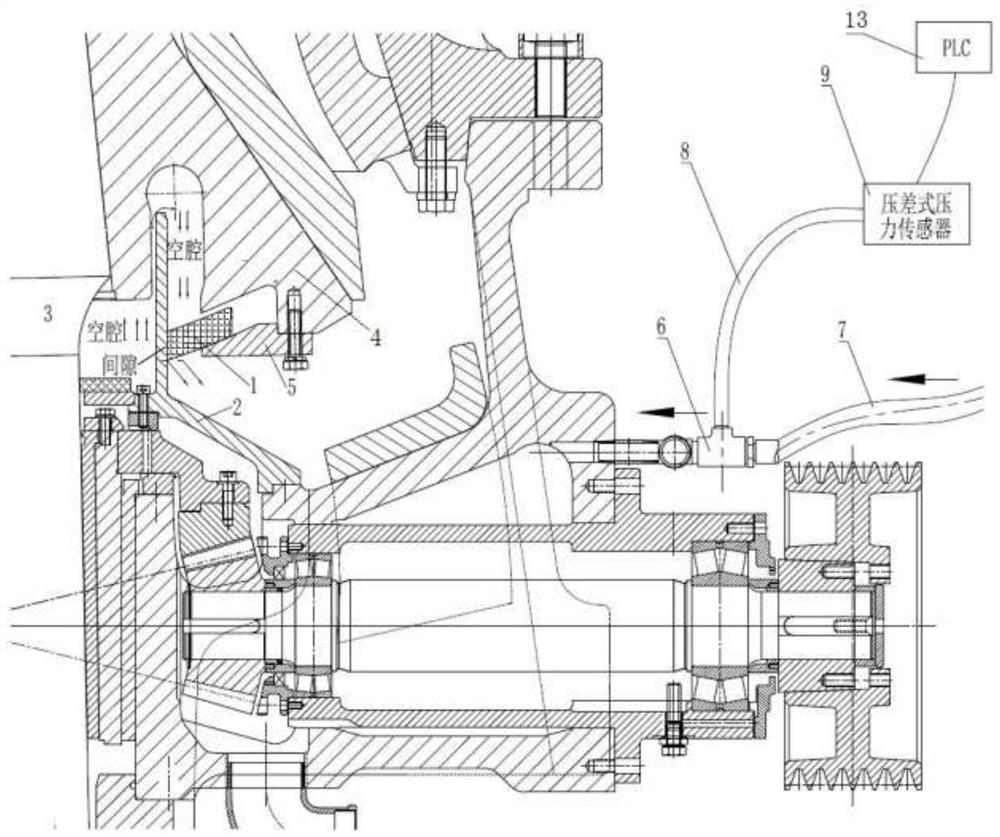

[0017] Such as figure 1 As shown, the cavity of the cone crusher is a cavity formed between the dust ring 1, the dust cover 2, the main shaft 3, the cone 4, the pressure seat 5 and other components, the dust ring 1 and the dust cover 2 There is a very small gap between them to ensure the formation of airflow channels inside and outside, so that it forms a structure in which the internal air is greater than the external air.

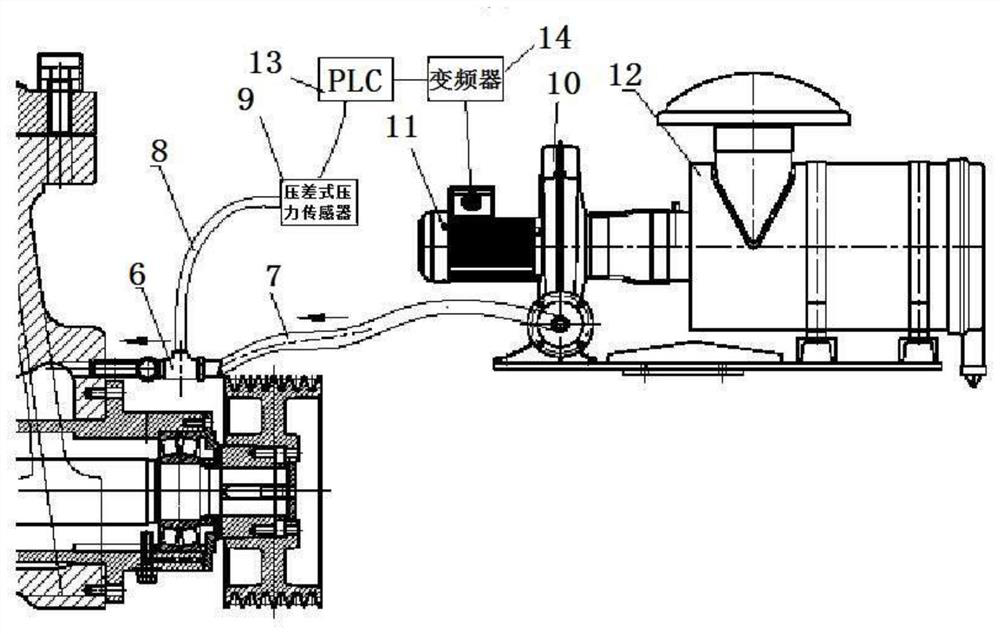

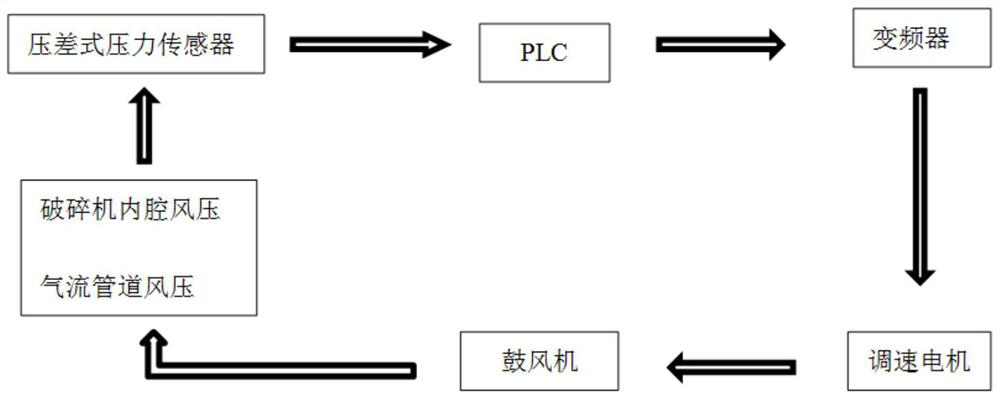

[0018] The wind pressure intelligent control system of the positive pressure dust prevention system of the cone crusher provided by the present invention is as follows: figure 2 As shown, it includes a T-joint 6 connected to the positive pressure dust-proof air inlet of the dust cover 2. The T-joint 6 is connected to the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com