Self-elevating box-type culture platform

A self-elevating, box-type technology, used in fish farming, ship parts, climate change adaptation, etc., can solve the problems of high transportation and offshore installation costs of aquaculture platforms, platform laying, and high installation costs, and shorten the supply and fish consumption. The effect of similar fishing and transportation paths and strong anti-deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

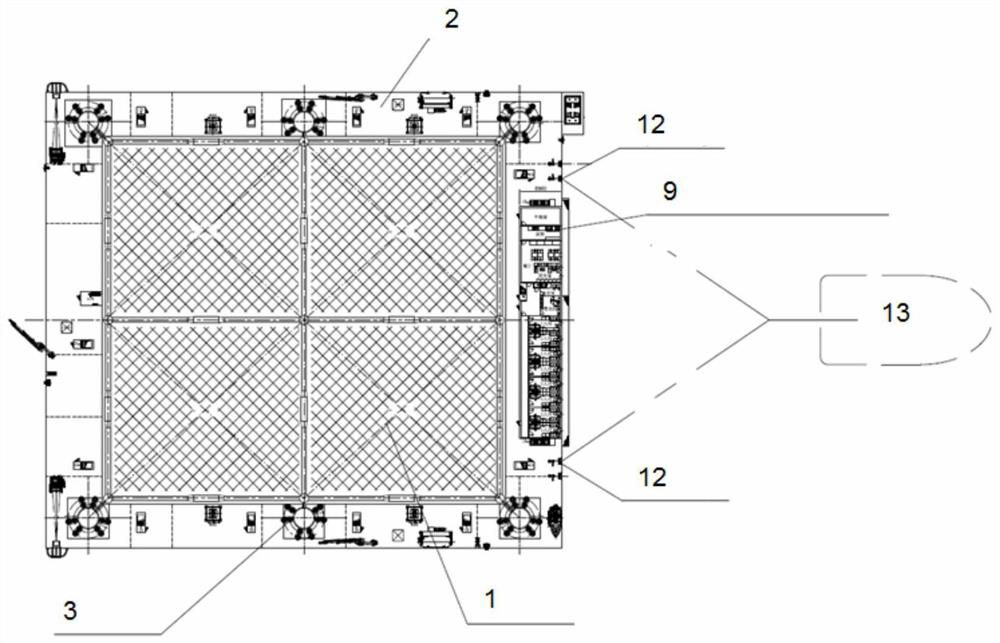

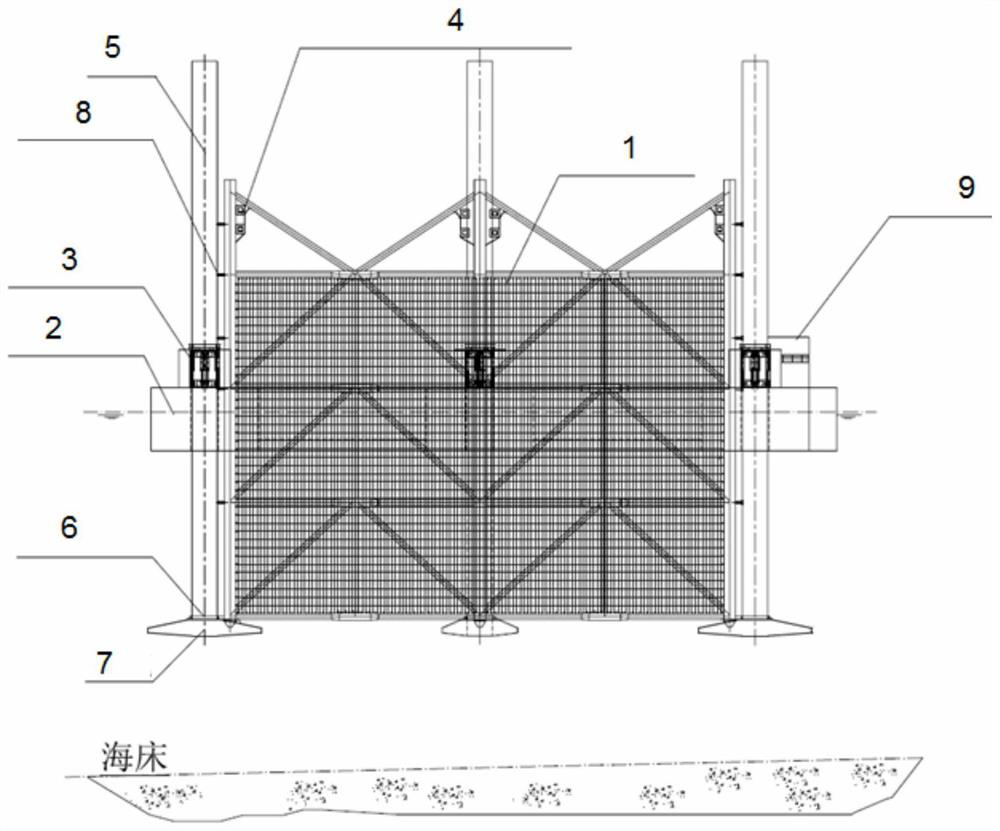

[0032] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0033] Such as Figure 1 to Figure 7 As shown, a self-elevating box type culture platform of the present invention comprises a culture net cage 1, and surrounds a structure hull 2 fixed on the periphery of the culture net cage 1; the structure hull 2 includes a lifting device 3 and a locking system 14, and The legs 5 pass through the structural hull 2, and are slidably connected with the structural hull 2 by the lifting device 3. The bottom of the legs 5 is provided with a spud shoe 7; The bottom of the culture cage 1 is provided with a guide structure 6 for moving up and down along the legs 5; the lower guide structure 6 of the culture cage 1 is supported on the legs 5 during construction and migration at sea, and falls on the spud shoes 7 simultaneously, When arriving at the breeding sea area, the breeding net cage 1 and the pile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com