Method and system for quick turn-off of bidirectional thyristor

A technology of bidirectional thyristors and thyristors, which is applied in the direction of output power conversion devices, electrical components, reactive power adjustment/elimination/compensation, etc. It can solve problems such as damage to thyristors, difficulty in detecting current direction, and thyristor current spikes, etc., to reduce Effect of off-time, reliable and fast turn-off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

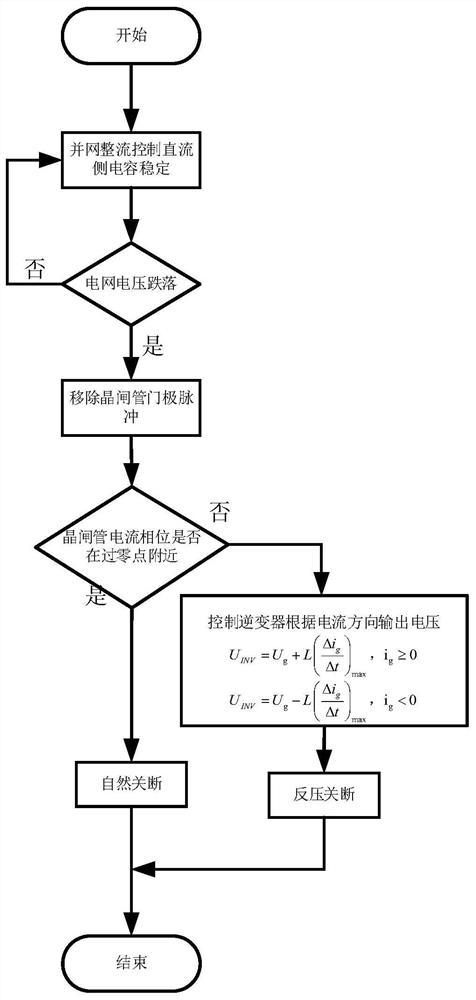

[0044] The following will be combined with specific drawings to describe in detail specific embodiments of the present invention. It should be noted that the technical features described in the following embodiments or combinations of technical features should not be considered isolated, they may be combined with each other to achieve better technical results.

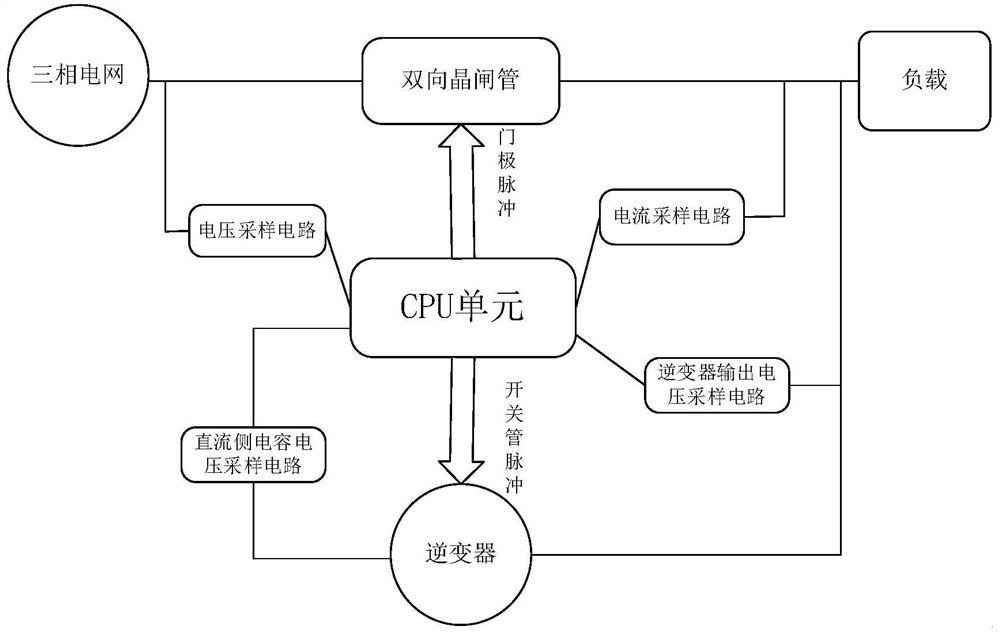

[0045] Figure 1 Schematic diagram of the overall structure of an embodiment of the present invention is shown a bidirectional thyristor fast shutdown system.

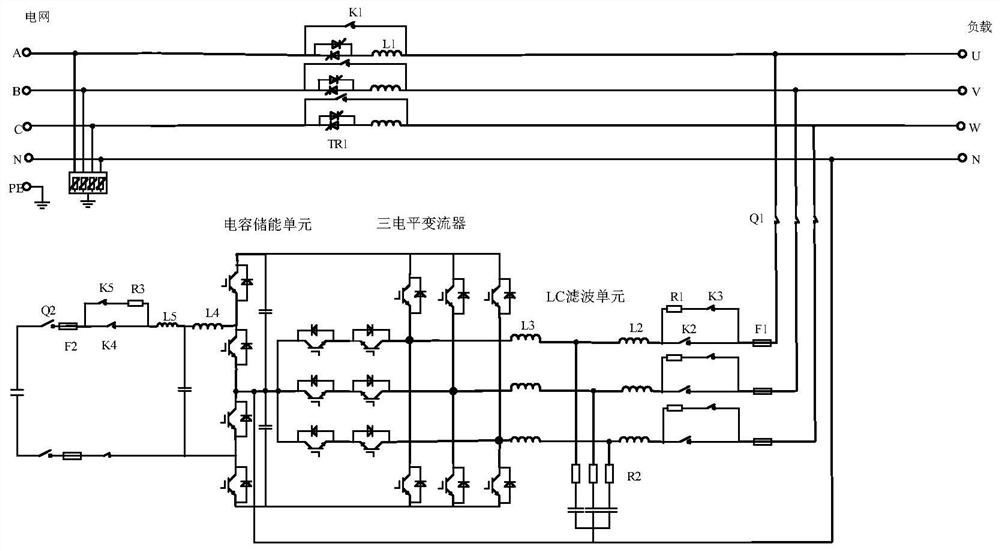

[0046] In one specific embodiment, the bidirectional thyristor fast shutdown system comprises a three-phase power grid, a bidirectional thyristor, load LOAD, a three-level inverter, an LC filter unit, a voltage current detection unit, a capacitor energy storage unit. The positive input of the three-phase grid voltage is connected to one end of the three sets of bidirectional thyristor abc, and the other end of the three sets of bidirectional thyristor abc is conne...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap