Hot air baffle structure for cooking device and oven

A technology of baffle structure and cooking device, which is applied in applications, cooking utensils, kitchen utensils, etc. It can solve the problems of decreased uniformity of gas field, increased wind resistance of fan blades of hot air blower, air flow loss, etc., so as to ensure the uniformity of air intake Sexuality, avoiding loss of air volume, avoiding the effect of airflow escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

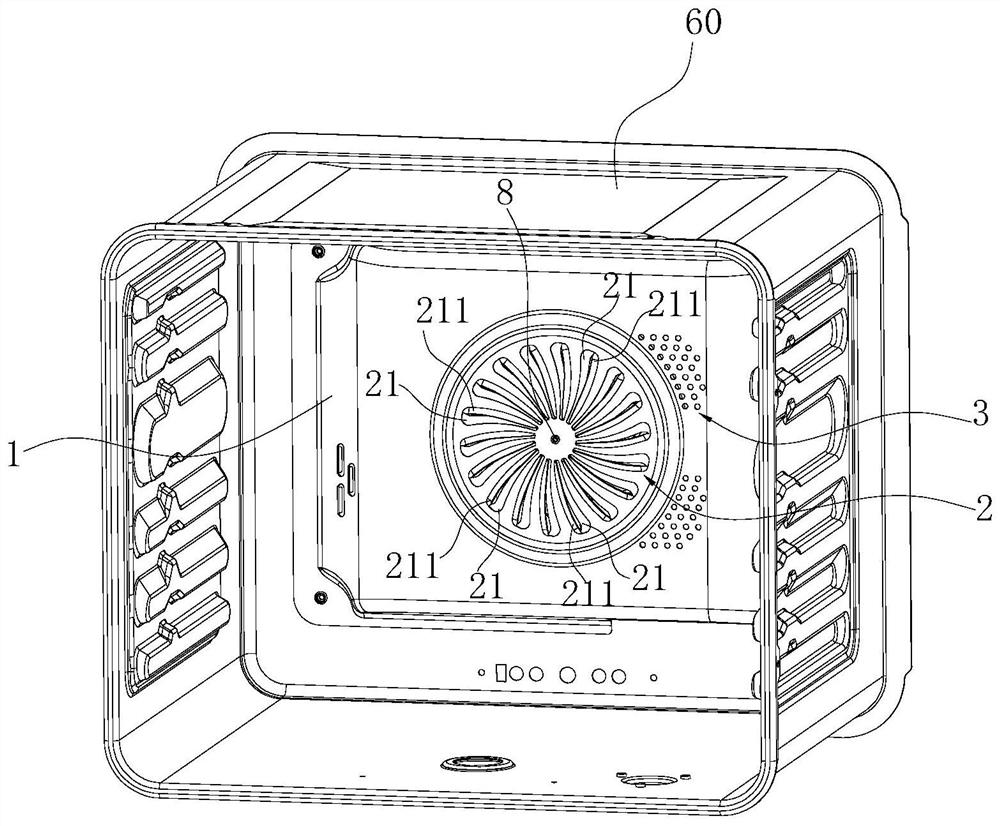

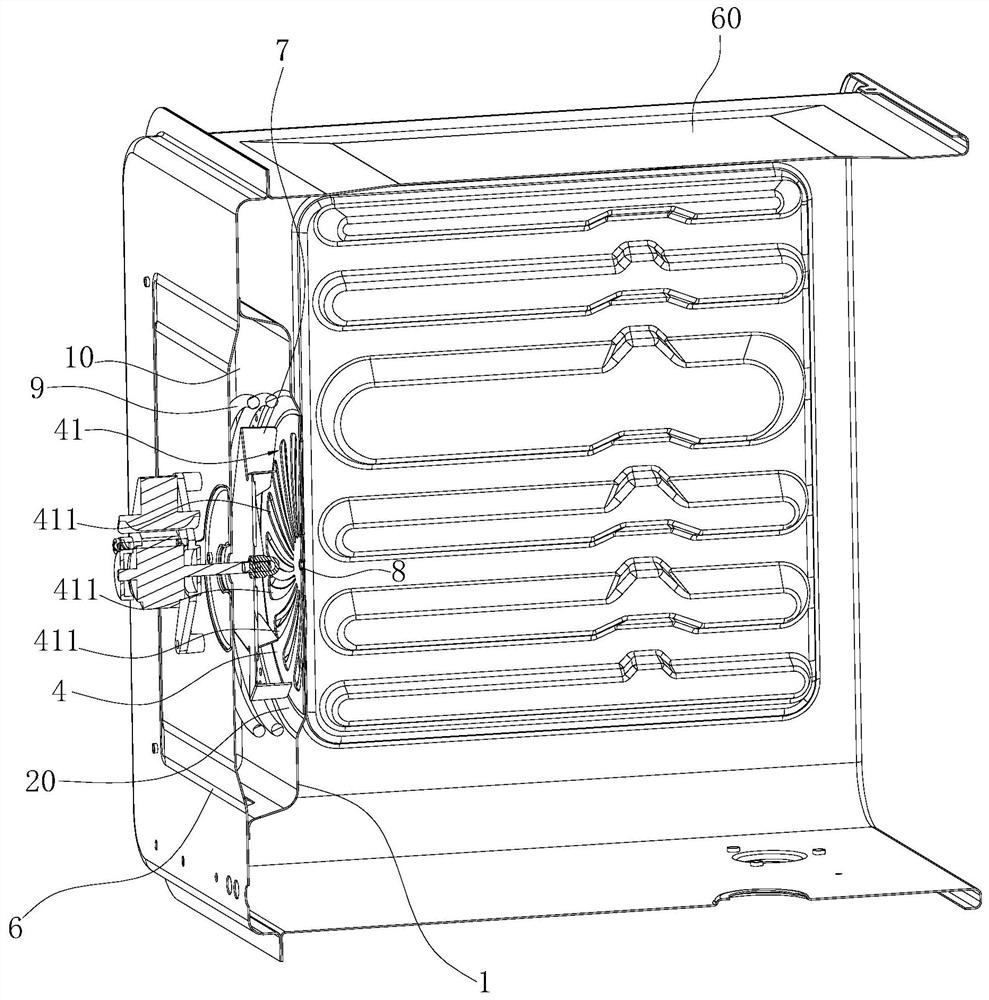

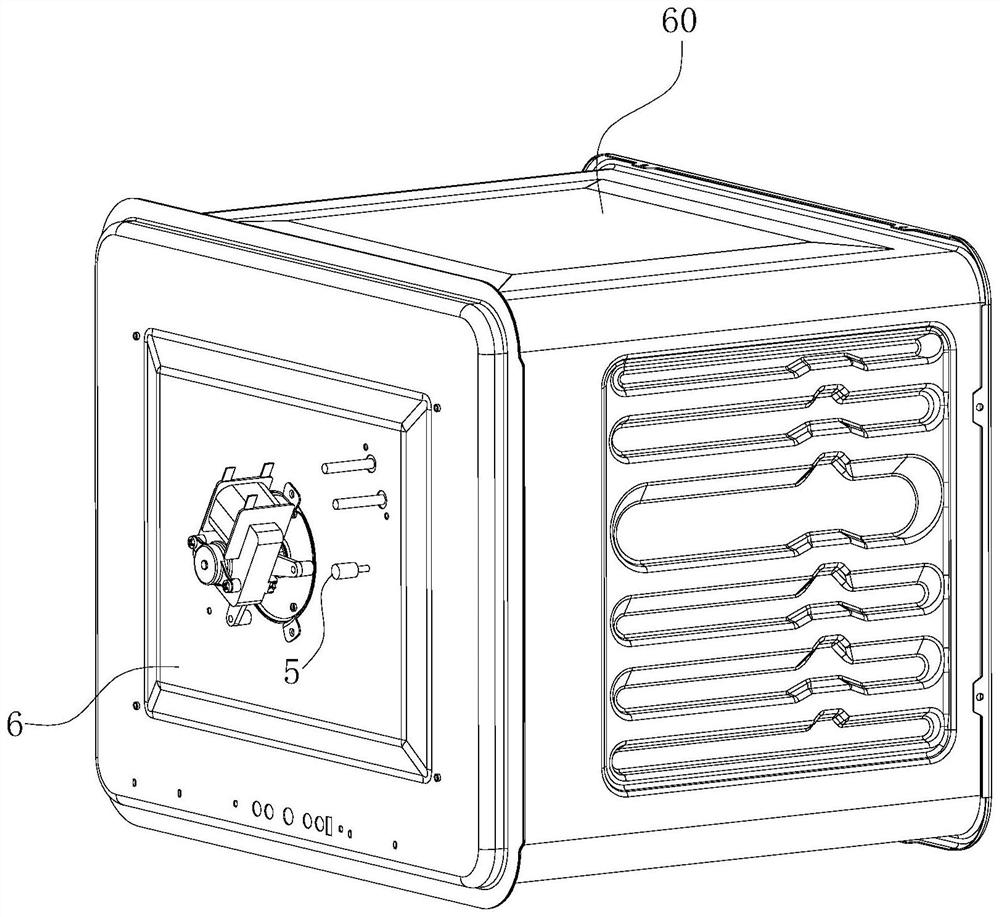

[0029] Such as Figure 1-7 As shown, an oven includes a hot air baffle structure, the hot air baffle structure includes a hot air baffle 1, and the hot air baffle 1 is covered on the back plate 6 of the inner container 60 to form a hot air chamber 10, the hot air chamber Heat fan blade 7 is installed in 10, and the outer periphery of this heat fan blade 7 is provided with heating pipe 9, and the center of above-mentioned hot air baffle plate 1 is provided with and is opposite with above-mentioned heat fan blade 7 front and back and concentric axis (being both The circular air inlet 2 is provided with the center of circle on the same straight line), and the peripheral side of the air inlet 2 is provided with an air outlet 3 . There are two kinds of present embodiment, the shape of the above-mentioned heating tube 9 is circular.

[0030] Furth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com