A method for disassembling and assembling a blade-type high-pressure fan of a turbogenerator

A turbo-generator and vane-type technology, which is applied in the manufacture of stator/rotor bodies, etc., can solve the problems of low maintenance efficiency of turbo-generator sets, the risk of mechanical injury to large-scale maintenance personnel, and low efficiency of turbo-generator maintenance. The effect of shortening the driving time, shortening the overhaul period, and increasing the space for disassembly and assembly operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

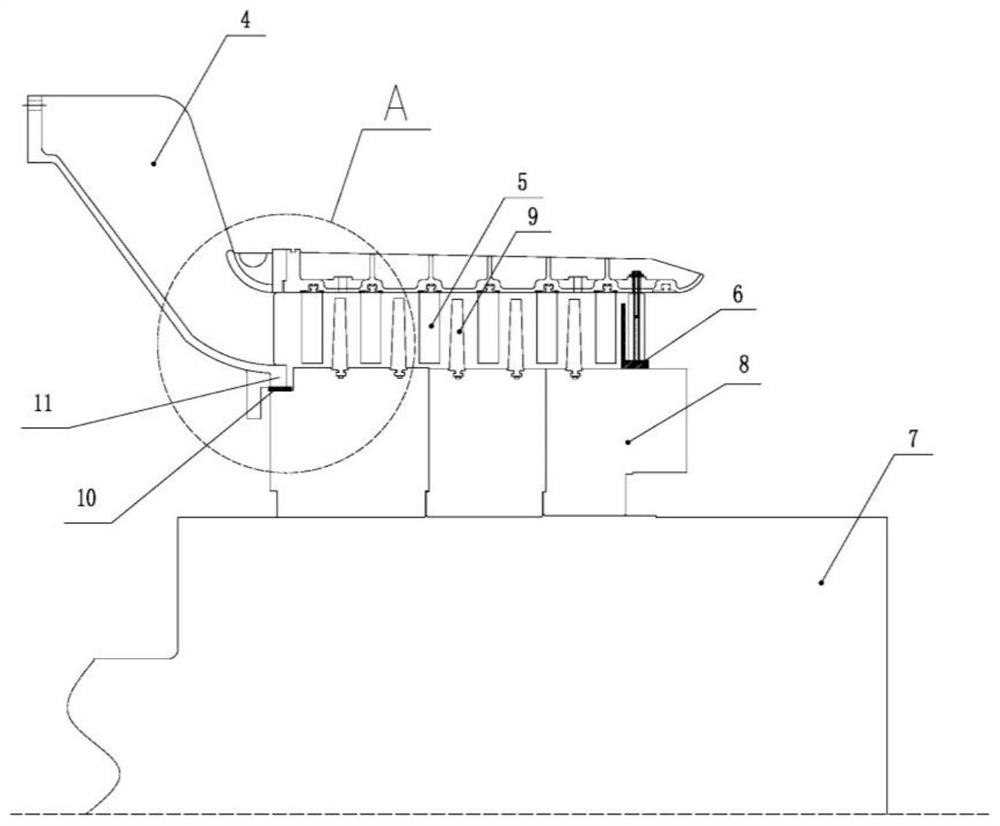

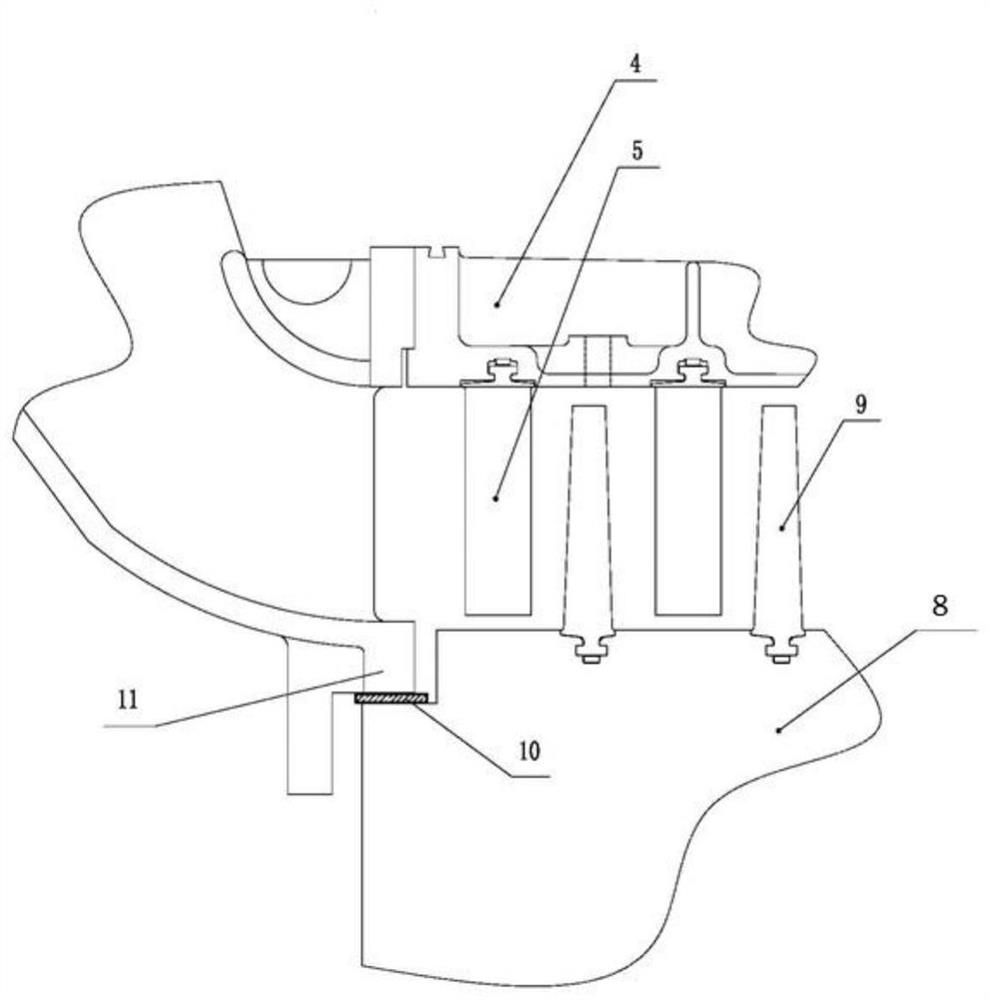

[0047] Such as Figure 1-3 As shown, a method for disassembling a turbogenerator blade-type high-pressure fan provided by the present invention, the method includes the following steps:

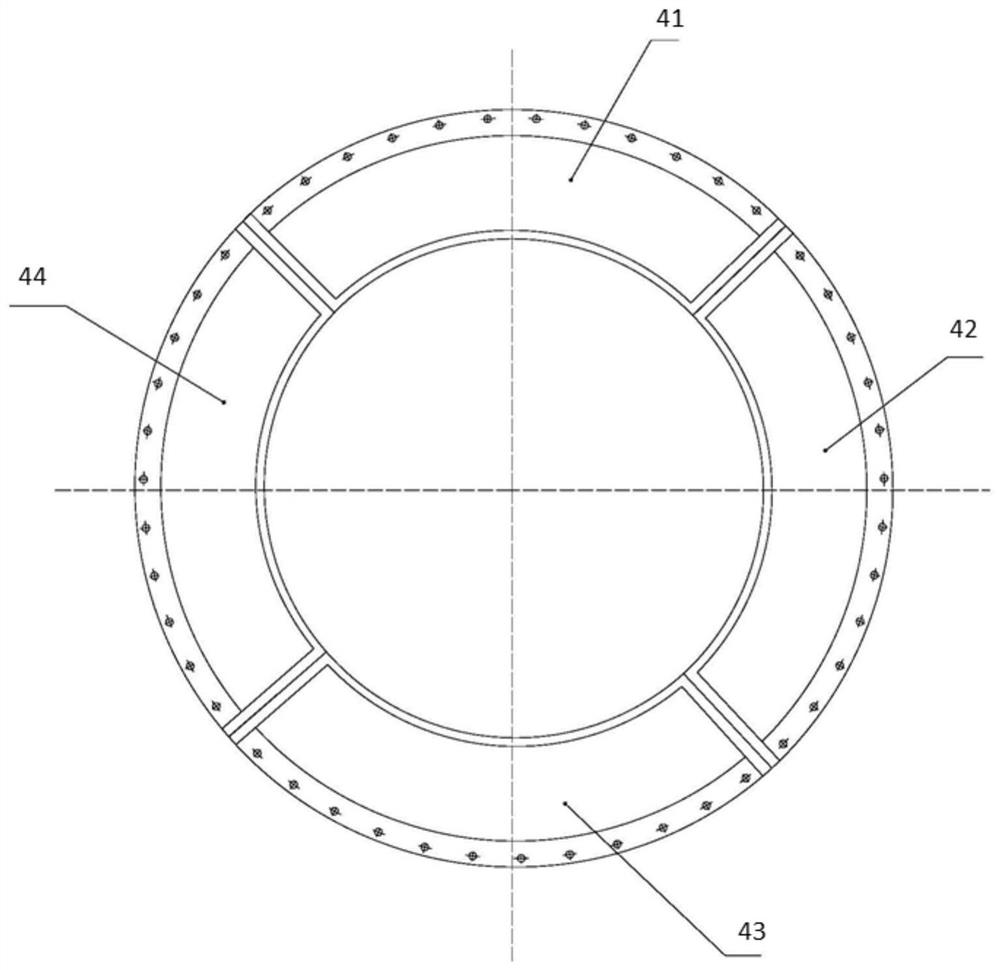

[0048] Step (A1), removing the upper fan cover 41;

[0049] Step (A2), install a fan cover dismounting ring 6 at the tail of the high-pressure fan cover 4, and install a sliding gasket 10 in the gap between the high-pressure fan cover radial limit block 11 and the fan seat ring 8, for reducing Small sliding part friction;

[0050] Step (A3), rotate the remaining fan cover clockwise, place the left fan cover 44, the lower fan cover 43 and the right fan cover 42 directly above and remove them;

[0051] Step (A3.1), rotate the remaining 3 fan covers clockwise so that the left fan cover 44 is placed directly above and removed;

[0052] Step (A3.2), rotate the remaining 2 fan covers clockwise so that the lower fan cover 43 is placed directly above and removed;

[0053] Step (A3.3), rotate the ...

Embodiment 2

[0058] Such as Figure 1-3 As shown, the present invention provides a method for installing a turbogenerator blade-type high-pressure fan, the method comprising the following steps:

[0059] Step (B1), installing all moving fan blades 9;

[0060] Step (B2), install a fan cover dismounting ring 6 at the tail of the high-pressure fan cover 4, install a sliding gasket 10 in the gap between the high-pressure fan cover radial limit block 11 and the fan seat ring 8, for reducing Small sliding part friction;

[0061] Step (B3), install the left fan cover 44, the lower fan cover 43 and the right fan cover 42 sequentially directly above, and rotate each fan cover clockwise by 90°;

[0062] Step (B3.1), install the left flap fan cover 44 directly above and rotate it 90° clockwise;

[0063] Step (B3.2), install the lower flap fan cover 43 directly above and rotate it 90° clockwise;

[0064] Step (B3.3), install the right flap fan cover 42 directly above and rotate it 90° clockwise;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com