A thermal vibration test device and test method based on shape-position equivalent reverse deduction control

A technology of reverse thrust control and test method, applied in vibration testing, measuring devices, testing of machine/structural components, etc., can solve the problem that the testing technology cannot meet the vibration testing and other problems, and achieve short test preparation period, low cost, and simple debugging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

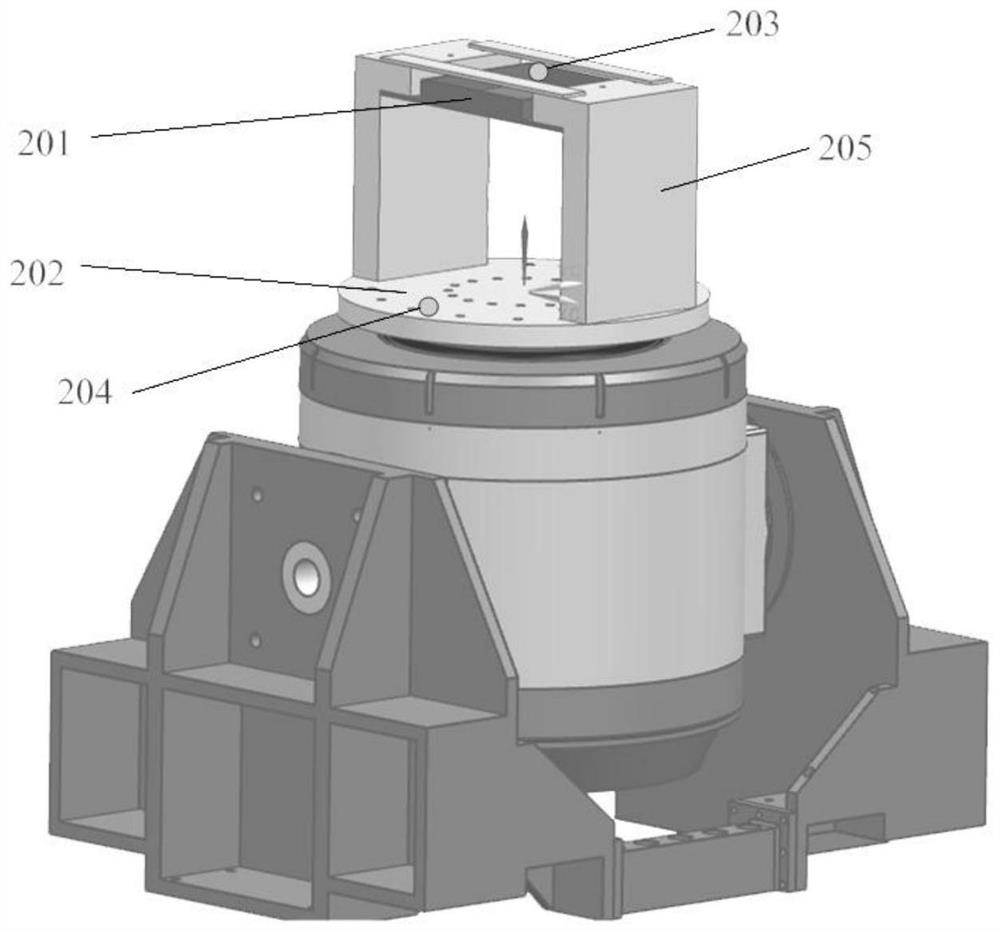

[0045] The test device includes a test shaker, a heat source, a tooling 205, a temperature sensor and an acceleration sensor. Shaker includes

[0046] The tooling 205 is installed on the vibrating table table 202, and the tooling 205 is used for clamping the test piece 201.

[0048] A heat source is used to heat the test piece 201. Preferably, the heat source in the embodiment of the present invention is a quartz lamp heater, a quartz lamp

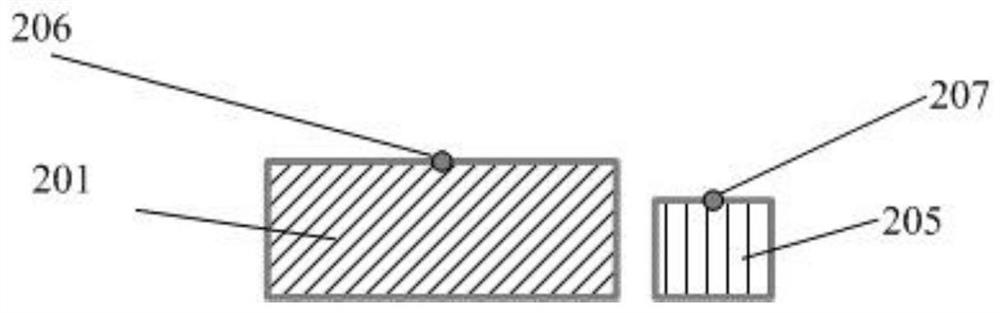

[0049] The temperature sensor includes a first temperature sensor 206 and a second temperature sensor 207, the first temperature sensor 206

Embodiment 2

[0060] The vibration conditions given in the embodiment of the present invention include a frequency range (random vibration takes 20 to 2000 Hz), a total mean square

[0079] Specifically, first remove the first temperature sensor 206 on the test piece 201. According to the equivalence relationship of shape and position, to debug

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com