Assembly pose measurement precision pre-evaluation method based on Monte Carlo method

A technique of Monte Carlo method and measurement accuracy, which can be used in measurement devices, optical devices, instruments, etc., and can solve problems such as the accuracy of component pose measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

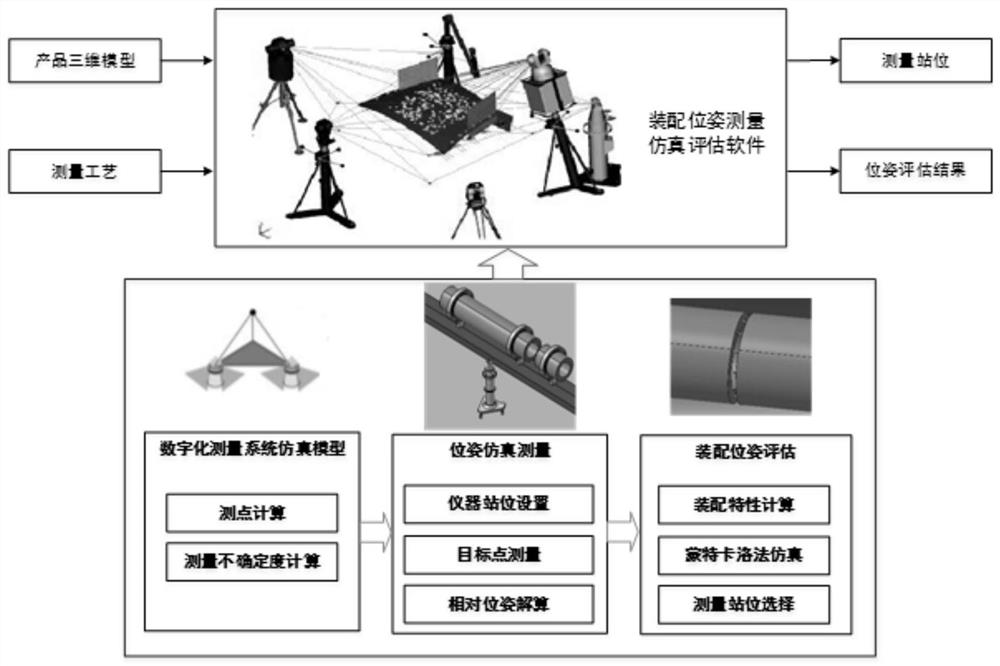

[0071] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Aiming at the pre-assessment of pose measurement accuracy in the digital assembly process of large parts, the present invention provides a calculation method based on the Monte Carlo method for pose fluctuations and assembly characteristics, and according to figure 2 The software system shown is implemented.

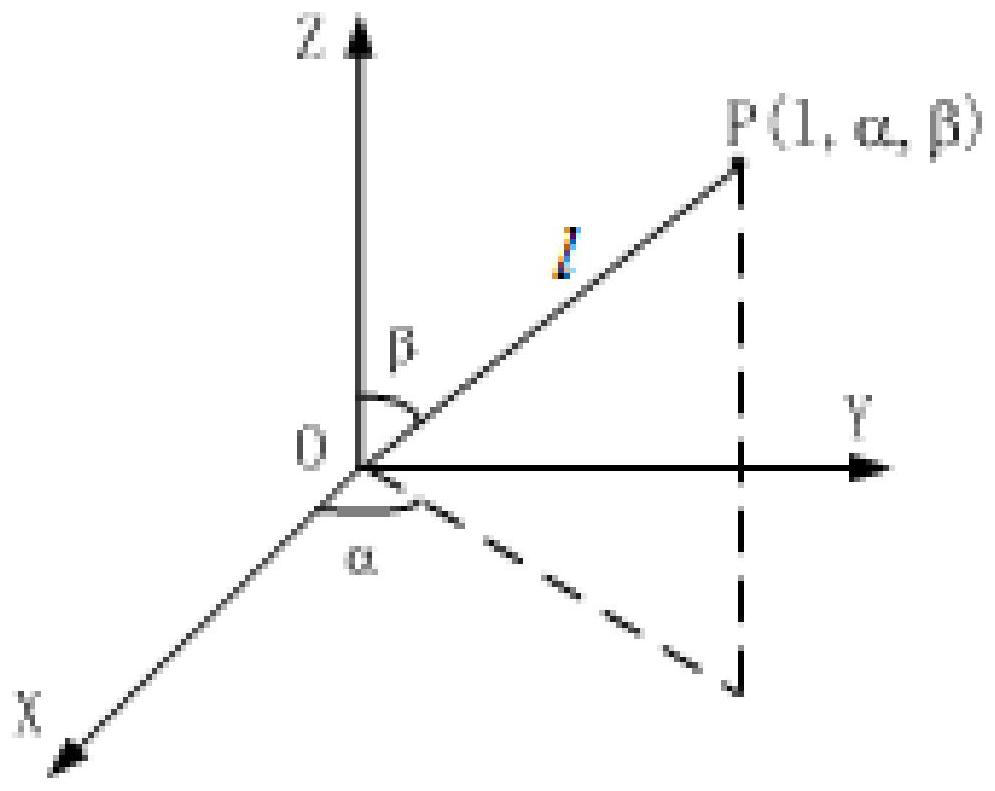

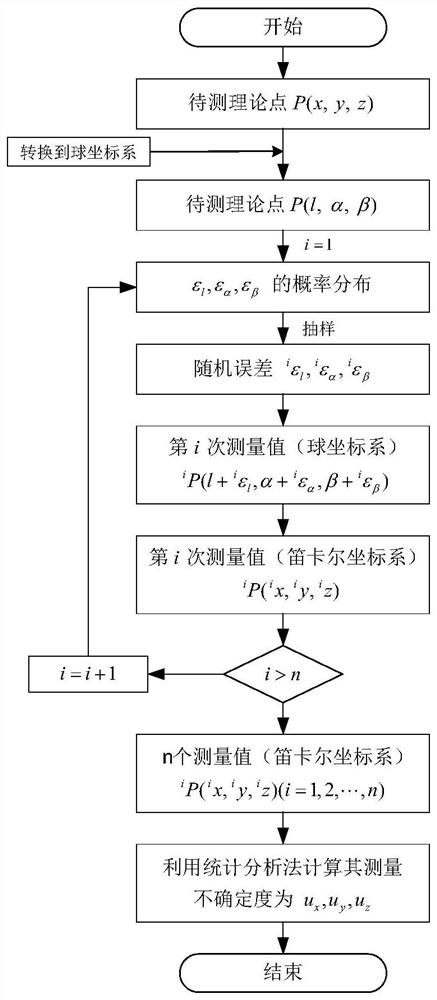

[0072] For the simulation model of the digital measurement system, see image 3 , Figure 4 , taking the laser tracker as an example to build its measurement model, and give the simulation measurement method of the target point coordinates. There is a distance measuring sensor and two angle measuring sensors inside the laser tracker, which can measure the distance l, horizontal angle α and vertical angle β from the instrument to the measured target point P, forming polar coordinates P=(l, α, β) T . In the application of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com