Matt ink for wall cloth, wall cloth and preparation method of wall cloth

A matte ink and wall covering technology, applied in the direction of ink, application, home appliances, etc., can solve the problems of difficult to see the plane pattern, single decorative effect of wall covering, and reducing the decorative effect of wallpaper.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The present invention also provides a kind of preparation method of wall cloth, comprises the following steps:

[0058] A) coating the waterproof slurry on the substrate layer, and obtaining the waterproof layer after drying;

[0059] B) printing ink on the surface of the waterproof layer to form a ground color layer after drying, and the ink is the matte ink for wall covering according to any one of claims 1 to 5;

[0060] C) printing ink on the surface of the background color layer to form a pattern layer, the ink is the matte ink for wall covering according to any one of claims 1 to 5, and the pattern layer is a plane pattern layer and / or a three-dimensional pattern layer pattern layer;

[0061] D) printing transparent pearl paste on the surface of the pattern layer, and forming a decorative effect layer after drying to obtain a wall covering.

[0062] In the present invention, the substrate layer is first flattened, the waterproof slurry is scraped and coated on t...

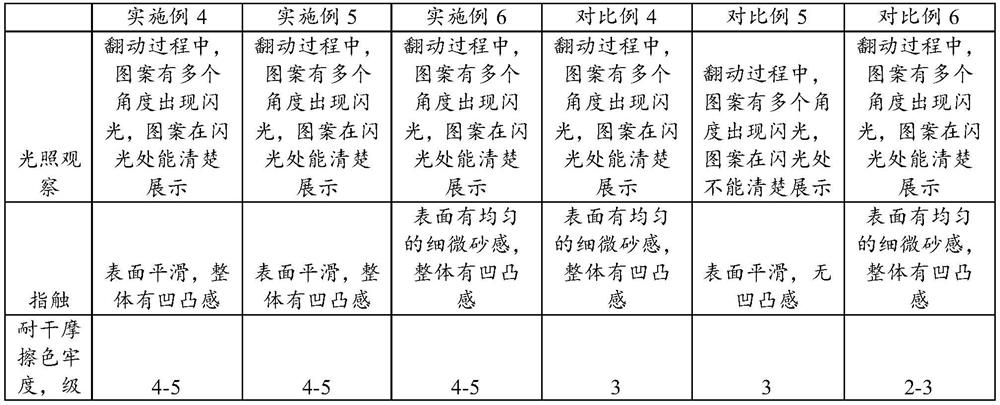

Embodiment 1

[0073] The solid content of the ink is 42%, and the matte degree is 7°. The ink comprises the following components in parts by mass: 40 parts of water-based acrylic resin; 50 parts of solvent; 10 parts of color paste; fatty alcohol polyoxyethylene ether and poly 7 parts of oxyethylene alkylamide; 60 parts of heavy calcium carbonate, nano silicon dioxide and nano dolomite; 0.5 part of dispersant; 1 part of stabilizer.

[0074] Among them, heavy calcium carbonate, nano silicon dioxide and nano dolomite are 7-15 μm.

Embodiment 2

[0076] The ink has a solid content of 52% and a matte degree of 10°. The ink comprises the following components by mass: 70 parts of water-based acrylic resin; 70 parts of solvent; 15 parts of color paste; alkylphenol polyoxyethylene ether and 8 parts of a mixture of polyoxyethylene sorbitan monolaurate; 75 parts of heavy calcium carbonate, nano silicon dioxide and nano dolomite combined filler; 1.5 parts of dispersant; 1.5 parts of stabilizer; antifungal agent and antibacterial agent combination 1 part of functional additives.

[0077] Among them, heavy calcium carbonate, nano silicon dioxide and nano dolomite are 0.3-8μm

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com