A rapid method for determination of flame retardant content in inorganic flame retardant cellulose fibers

A cellulose fiber and inorganic flame retardant technology, which is applied in the field of rapid testing of flame retardant content, can solve the problems of increased chemical use, poor method versatility, and chemical discharge, and achieve resource saving, small sample size, and analysis speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Example 1 Ambrose flame retardant cellulose fiber (the main flame retardant component is SiO 2 ) rapid determination of flame retardant content

[0070] The implementation process of this embodiment is as follows:

[0071] (1) Collect representative fiber samples with different flame retardant contents: collect 10 to 15 fiber samples at different time points in normal production batches and production transition batches, and the quantity of each sample is about 100g. Store in a sealed plastic bag for testing. The flame retardant content of the sample is between 10% and 35%, and the distribution is as uniform as possible;

[0072] (2) Determination of the flame retardant content of each sample by burning weighing method: according to the burning residue test method specified in Appendix A of FZ / T 52013-2011 "Inorganic Flame Retardant Viscose Staple Fiber", the flame retardant of each sample is determined. agent content;

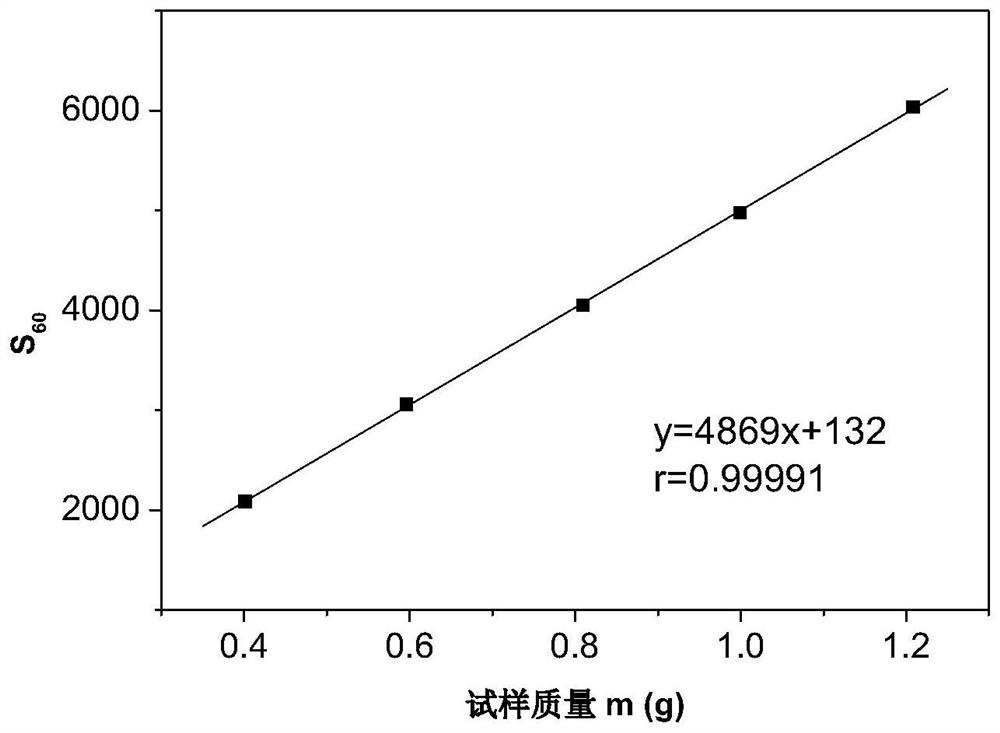

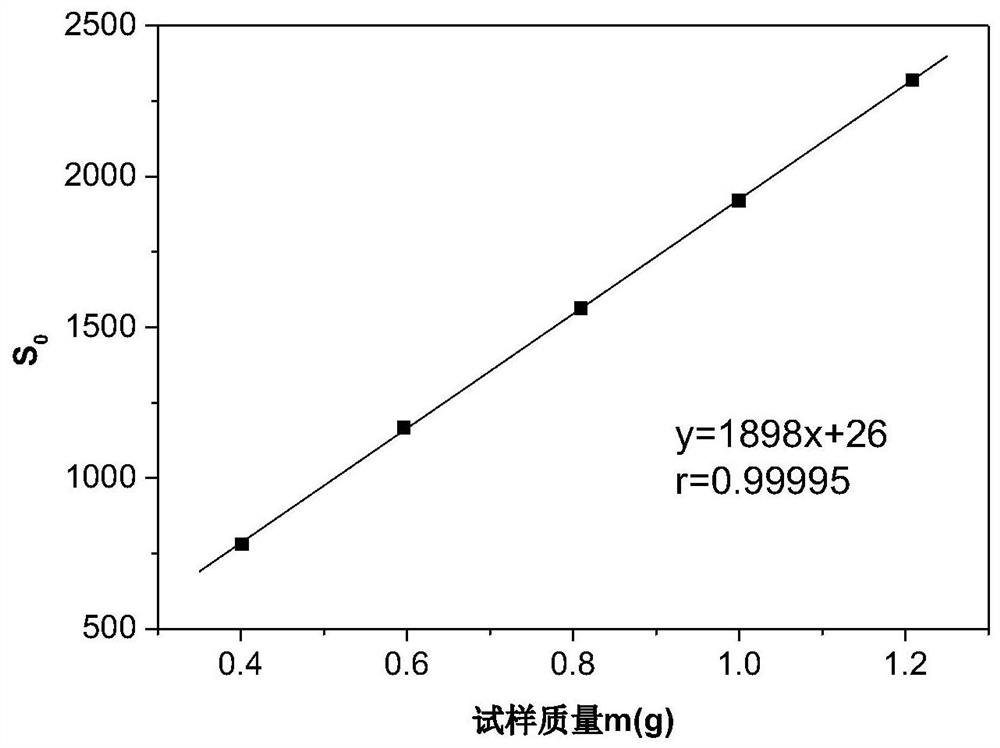

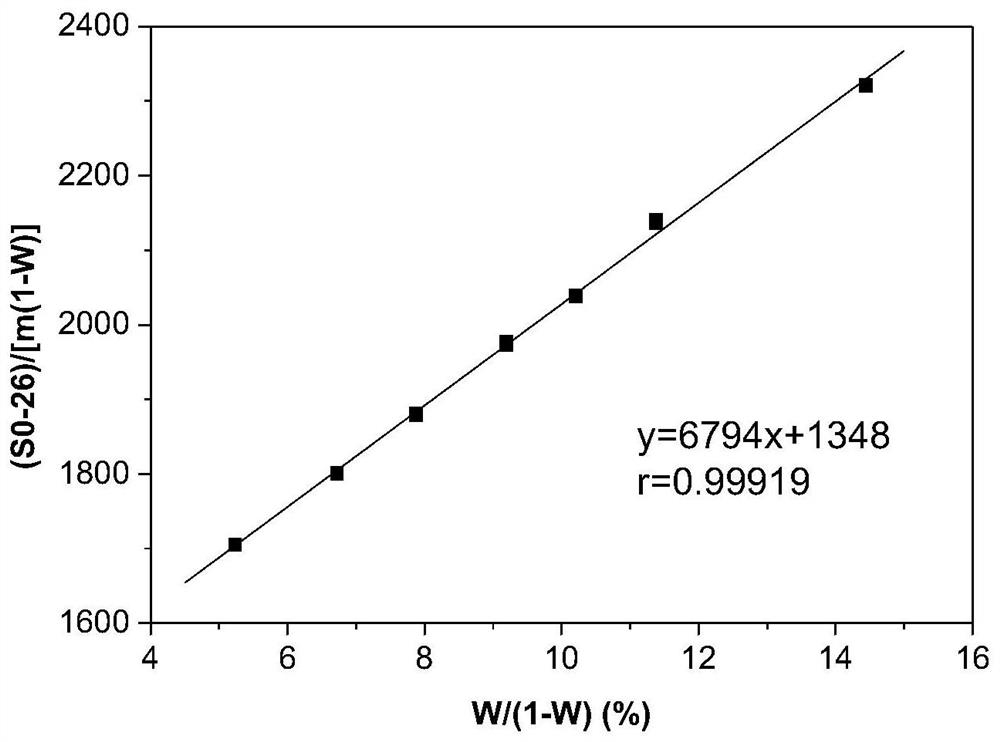

[0073] (3) Determination of the NMR FID signa...

Embodiment 2

[0126] Example 2 Rapid determination of flame retardant content of samples at non-calibrated temperature

[0127] The sample with known flame retardant content (sample weight is about 1g) is adjusted by a water bath or other constant temperature equipment, and the working curve and operation method established in Example 1 are used to obtain sample temperatures of 17°C and 20°C in turn. , 25°C, 28°C, 30°C, 34°C, and 38°C measurement results. Take the measured value X at different temperatures T is the ordinate, and the temperature T is the abscissa, draw the curve of the measured value of the flame retardant content with the temperature of the sample, such as Image 6 shown. It can be seen that in the temperature range of 15 ℃ ~ 40 ℃, the measured value of the flame retardant content of the sample increases with the increase of temperature, and the two are approximately in a linear relationship, and the relationship can be expressed as:

[0128] X T -X 0 =k 6 (T-T 0 ) (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com