Fiber bragg grating strain detection device

A detection device and fiber grating technology, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems of inconvenience of different specifications of fiber gratings and reduced detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

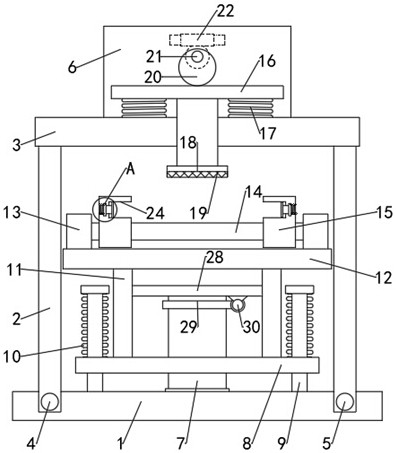

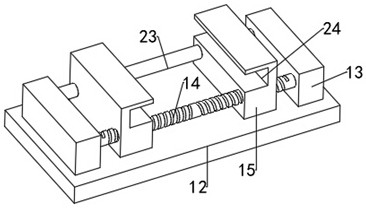

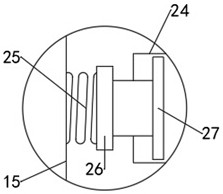

[0019] see Figure 1-3 , a fiber grating strain detection device, comprising a base 1, a support frame 2 is movably installed on the base 1, an end of the support frame 2 away from the base 1 is connected to a mounting seat 3, and the upper end surface of the mounting seat 3 is fixed with a Drive chamber 6, a pressure plate 16 is movable installed in the drive chamber 6, the cross section of the pressure plate 16 is T-shaped, the pressure plate 16 extends to the bottom of the mounting seat 3 and is connected with a pressure block 18, on the pressure block 18 A pressure sensor 19 is installed; a fixed seat 12 is movably installed on the base 1 , and a clamping mechanism is arranged on the fixed seat 12 to clamp the optical fiber grating to be tested. The clamping mechanism is located under the pressure block 18 .

[0020] Further, a pressure plate 16 is slidably installed in the drive chamber 6, and several vertical return springs 17 are evenly installed between the lower end s...

Embodiment 2

[0028] In order to make the base plate 8 rise and fall smoothly, this embodiment is improved on the basis of embodiment 1. The improvement is: the section of the guide rod 9 is T-shaped, and the guide rod 9 is located on the periphery of the upper end of the base plate 8. The guide spring 10 is used to improve the stability of the lifting of the substrate 8, which is convenient to use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com