Single-tower desulfurization ultra-clean treatment system and desulfurization process

A technology of treatment system and desulfurization process, which is applied in the field of single-tower desulfurization ultra-clean treatment system and desulfurization process, can solve the problems of substandard desulfurization, high cost and low efficiency of single-tower desulfurization and desulfurization, and achieve better desulfurization effect and dust removal effect Good effect with few changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

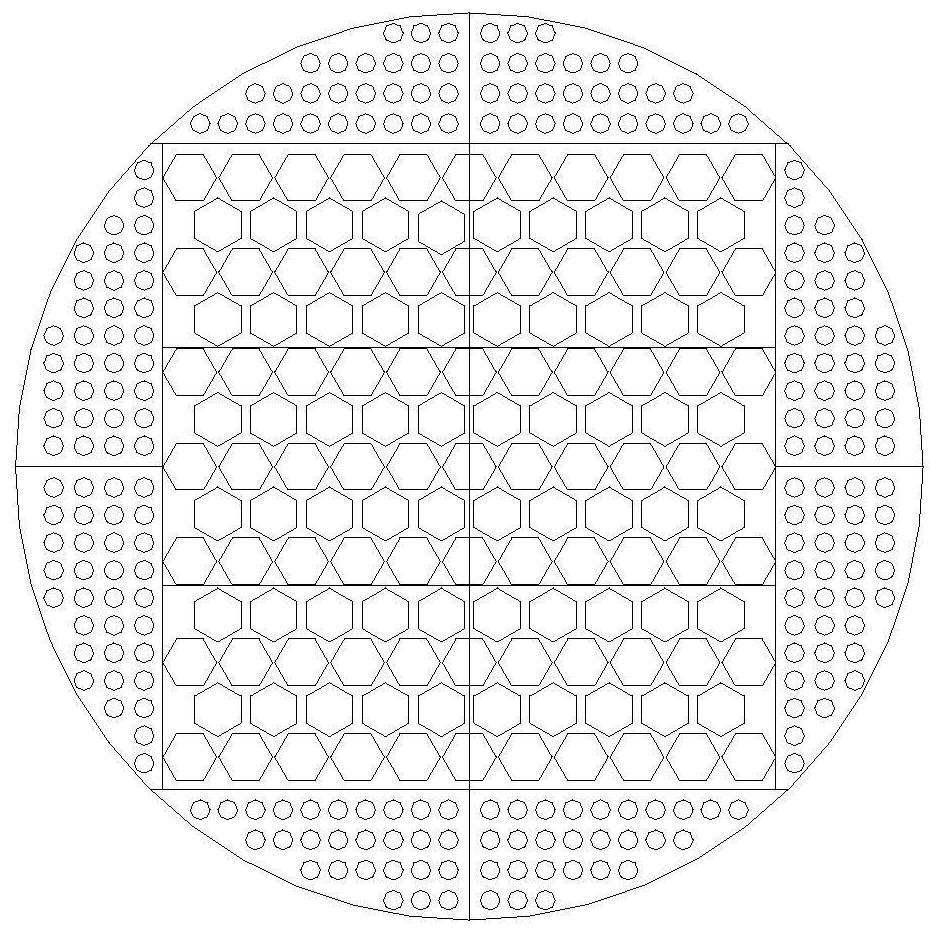

Image

Examples

Embodiment 1

[0050] A single tower desulfurization ultra-clean treatment process, comprising the following steps:

[0051] 1) The desulfurization liquid in the pre-spray circulation box 102 is sent to the pre-spray layer 104 through the pre-spray circulation pump 101, and the flue gas entering the flue 103 is subjected to pre-spray desulfurization; the liquid controlled by the pre-spray layer 104 The gas ratio is 0.5L / Nm 3 ;

[0052] 2) Control the induced draft fan and then control the flue gas after pre-spraying to enter the absorption tower 201 at a speed of 12m / s. At this time, the flue gas temperature at the inlet of the desulfurization tower is detected to be 105°C, and the average flow velocity of the flue gas in the absorption tower is controlled to be 3m / s, the slurry circulating pump 204 sends the desulfurization liquid in the absorption tower 201 to the spray layer 203 to spray and desulfurize the flue gas. The center line of the sprinkler pipe on the top floor of the device ...

Embodiment 2

[0055] The desulfurization treatment process steps are the same as in Example 1, and the liquid-gas ratio during pre-spraying is 0.3L / Nm 3 , control the induced draft fan and then control the flow rate of the flue gas entering the desulfurization tower to be 15m / s, and the temperature of the flue gas at the inlet of the desulfurization tower is 155°C; the average flow rate of the flue gas in the absorption tower is 4m / s, and other conditions remain unchanged. The gas is discharged from the flue gas outlet, and the SO2 at the outlet of the desulfurization tower is detected 2 The concentration value is 31mg / Nm 3 , the particle concentration value is 4.1mg / Nm 3 .

Embodiment 3

[0057] The desulfurization treatment process steps are the same as in Example 1, and the liquid-gas ratio during pre-spraying is 0.2L / Nm 3 , control the induced draft fan and then control the flow rate of the flue gas entering the desulfurization tower to be 15m / s, and the temperature of the flue gas at the inlet of the desulfurization tower is 180°C; the average flow rate of the flue gas in the absorption tower is 4m / s, and other conditions remain unchanged. The gas is discharged from the flue gas outlet, and the SO2 at the outlet of the desulfurization tower is detected 2 The concentration value is 35mg / Nm 3 , the particle concentration value is 4.3mg / Nm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com