Axial feed mechanism of perforating machine

A technology of axial feeding and feeding mechanism, which is applied in the direction of drilling/drilling equipment, parts of boring machine/drilling machine, metal processing equipment, etc., and can solve the problem of bulky and reliable drilling machine, complicated driving mechanism and limited scope of application And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] First of all, it needs to be explained that the definition of the upper and lower positional relationship in the present invention is described based on the state shown in the figure; the so-called axial feed refers to the axial forward and backward displacement of the drill rod spindle 20 connected to the tool, If the pipeline A to be drilled is taken as a reference object, it is the displacement in the radial direction of the pipeline A to be drilled.

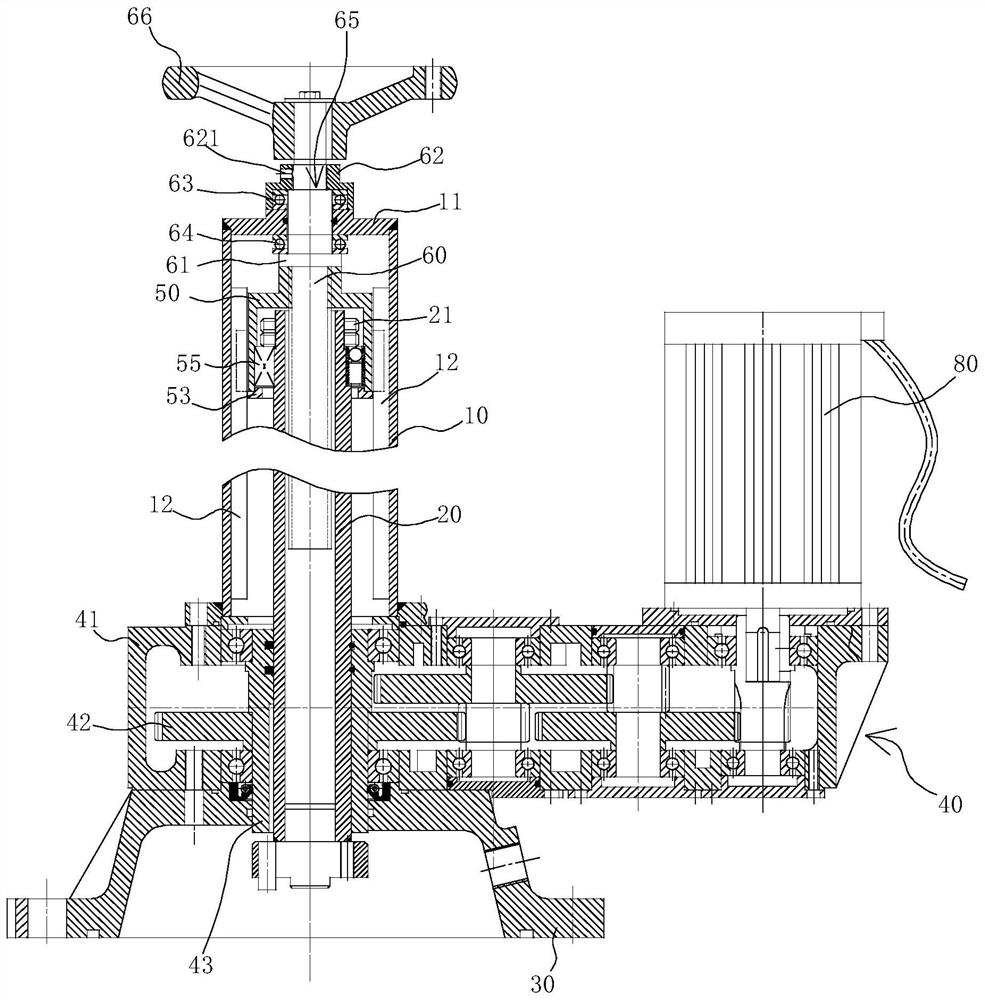

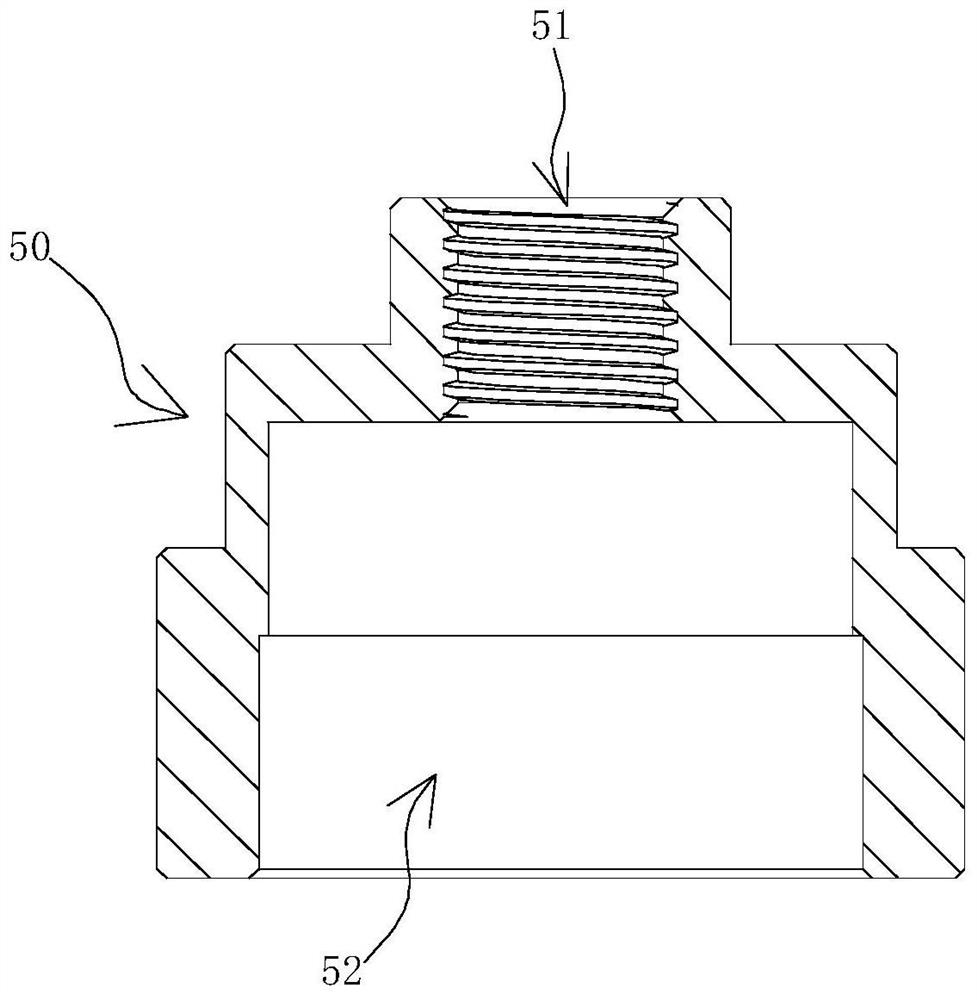

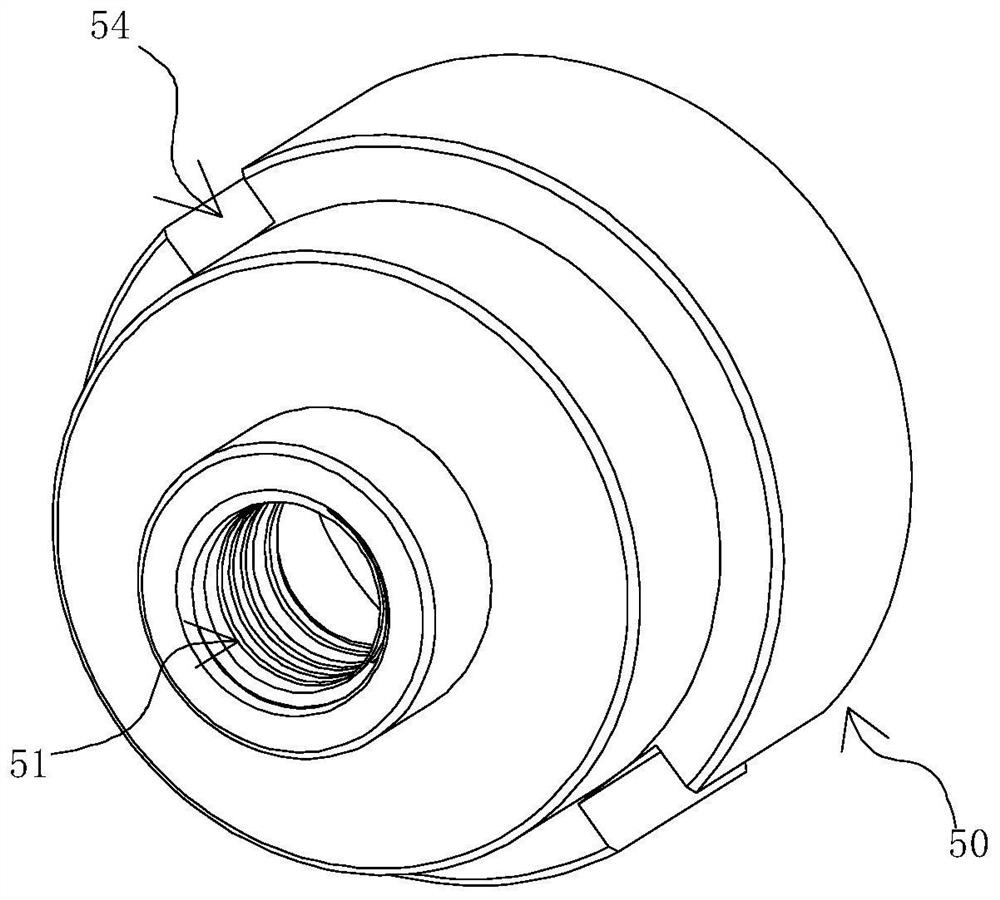

[0010] combine figure 1 , the axial feeding mechanism of the drilling machine, the tubular body 10 has a drill pipe main shaft 20 in the lumen, and the drilling pipe main shaft 20 connected with the knife feeding mechanism and the rotary drive mechanism performs circumferential rotation in the chamber of the tubular body 10, and the shaft To the displacement movement, the lower end of the drill rod main shaft 20 is used to connect the tool, and the shell seat 30 connected to the lower end of the tubular body 10 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com