Foamed light diffusion plate and its preparation method and application

A light diffusing plate and supercritical fluid technology, applied in the field of diffusing plates, can solve the problems of easy residual harmful chemical reagents, increasing manufacturing costs, and restricting usage scenarios.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

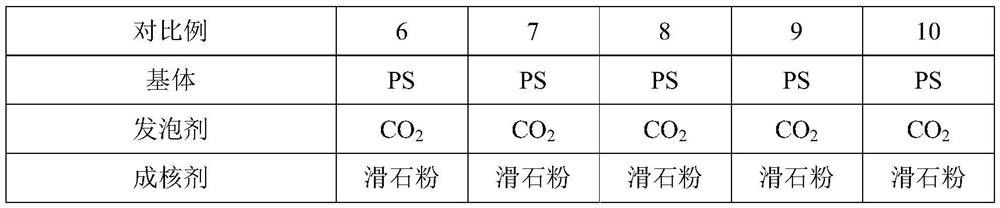

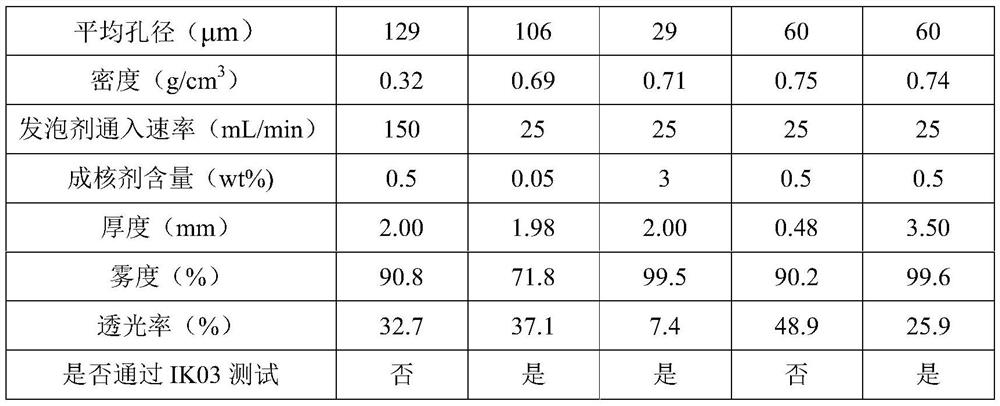

Examples

preparation example Construction

[0021] One aspect of the present invention provides a method for preparing a foamed light diffusing plate, comprising the following steps: under a pressure of 15MPa to 20MPa, inject supercritical fluid into the molten raw material of the foamed light diffusing plate, and mix uniformly After being extruded into a normal pressure environment, the supercritical fluid forms bubbles to produce a foamed light diffusion plate; the feeding rate of the supercritical fluid is 10mL / min~100mL / min, optionally, the feeding rate of the supercritical fluid For example, it can be: 20mL / min, 30mL / min, 40mL / min, 50mL / min, 60mL / min, 70mL / min, 80mL / min, 90mL / min, preferably, the feed rate of supercritical fluid is 15mL / min ~60mL / min; the appropriate supercritical fluid feed rate enables the supercritical fluid and the matrix to better form a homogeneous melt, and maintains a moderate expansion ratio, so that the formed cell size can be maintained at an appropriate Within the range, the prepared fo...

Embodiment 1

[0046] 1. Polystyrene chips and 8wt% nucleating agent are mixed and granulated in a twin-screw extruder to obtain a nucleating agent masterbatch. The temperature of each section of the twin-screw extruder is as follows: the temperature of the first zone is 180°C, the temperature of the second zone is 240°C, the temperature of the third zone is 235°C, the temperature of the fourth zone is 235°C, the temperature of the fifth zone is 230°C, the temperature of the sixth zone is 230°C, and the head The temperature is 225°C.

[0047] 2. Mix the nucleating agent masterbatch and the polystyrene chips in a certain proportion, and the conversion ratio of the nucleating agent is 0.5wt%. Put the above mixture into a twin-screw extruder for plasticizing and melting. The temperature of each section of the twin-screw extruder is as follows: the temperature of the first zone is 175°C, the temperature of the second zone is 185°C, the temperature of the third zone is 195°C, the temperature of ...

Embodiment 2

[0051] 1. Polystyrene chips and 8wt% nucleating agent are mixed and granulated in a twin-screw extruder to obtain a nucleating agent masterbatch. The temperature of each section of the twin-screw extruder is as follows: the temperature of the first zone is 180°C, the temperature of the second zone is 240°C, the temperature of the third zone is 235°C, the temperature of the fourth zone is 235°C, the temperature of the fifth zone is 230°C, the temperature of the sixth zone is 230°C, and the head The temperature is 225°C.

[0052] 2. Mix the nucleating agent masterbatch and the polystyrene chips in a certain proportion, and the conversion ratio of the nucleating agent is 0.7wt%. Put the above mixture into a twin-screw extruder for plasticizing and melting. The temperature of each section of the twin-screw extruder is as follows: the temperature of the first zone is 175°C, the temperature of the second zone is 185°C, the temperature of the third zone is 195°C, the temperature of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com