Environment-friendly flowback fluid treatment device

A treatment device and flowback liquid technology, applied in the direction of filtration treatment, special treatment targets, water/sewage treatment, etc., can solve problems such as inconvenient and inconvenient treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

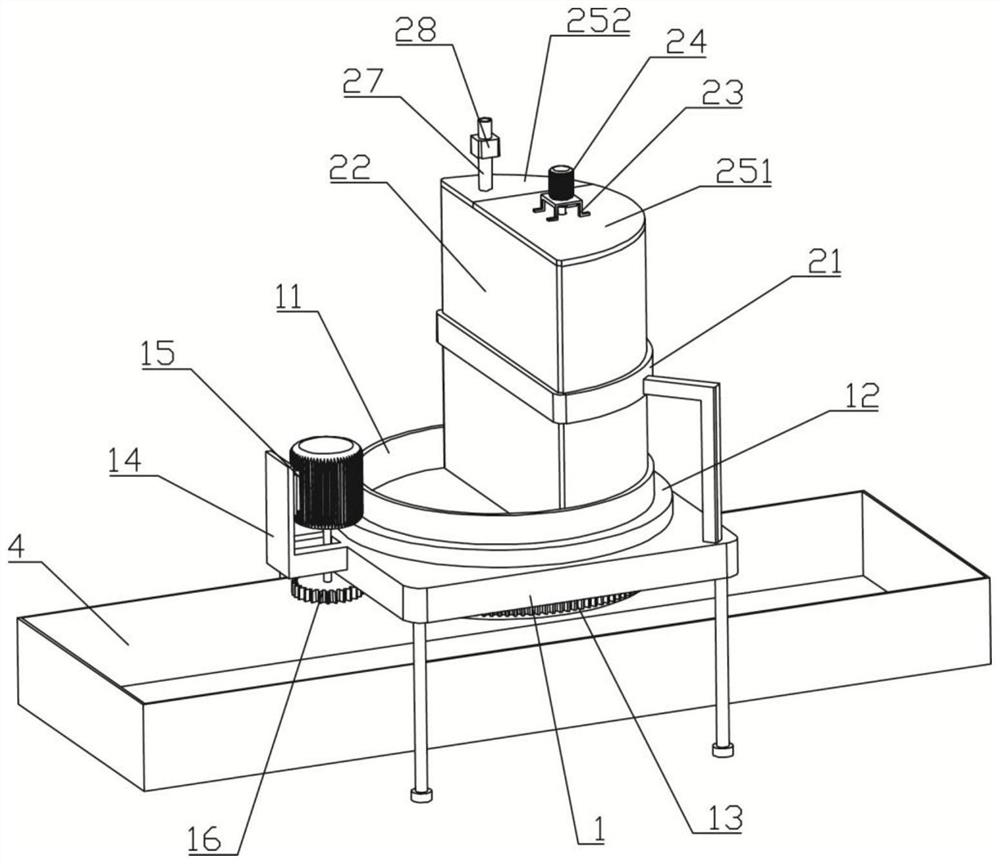

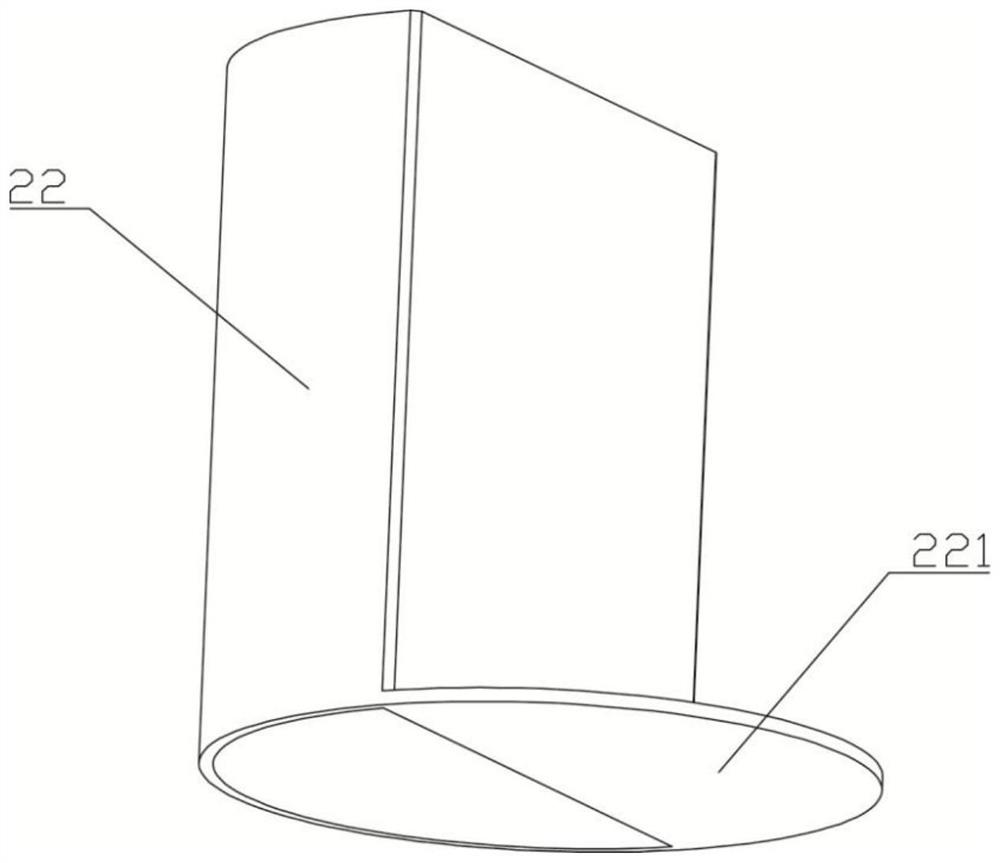

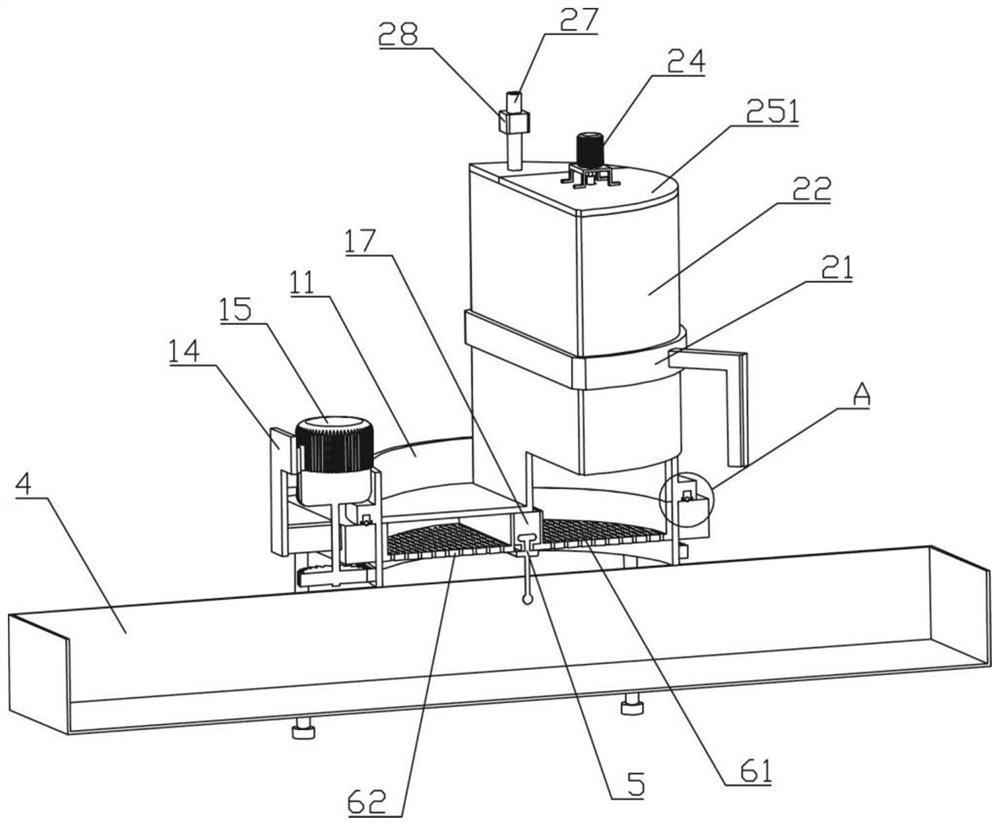

[0034] Such as Figure 1-9 As shown, an environment-friendly flowback liquid treatment device includes a mounting frame 1 on which a transmission-connected filter mechanism and a rotating drive mechanism are mounted, the filter mechanism is rotatably mounted on the mounting frame 1, and a The tank frame 21, the filtrate tank 22 is installed on the tank frame 21, and the filtrate tank 22 is in the shape of a semi-cylindrical. It is characterized in that: the filter mechanism includes an integrally formed installation sleeve 11 and a load-bearing platform 12, and an isolation frame is installed in the installation sleeve 11 17. A first filter assembly 61 and a second filter assembly 62 are respectively installed on both sides of the spacer 17 in the installation sleeve 11. The first filter assembly 61 includes an integrated filter screen 611 and a storage tank 612. The second filter assembly The assembly 62 has the same structure as the first filter assembly 61, the first filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com