Cleaning machine

A washing machine and rack technology, applied in the field of washing machines, can solve the problems of complex structure of washing machines, discount of material cleaning effect, etc., and achieve the effect of saving water resources and improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

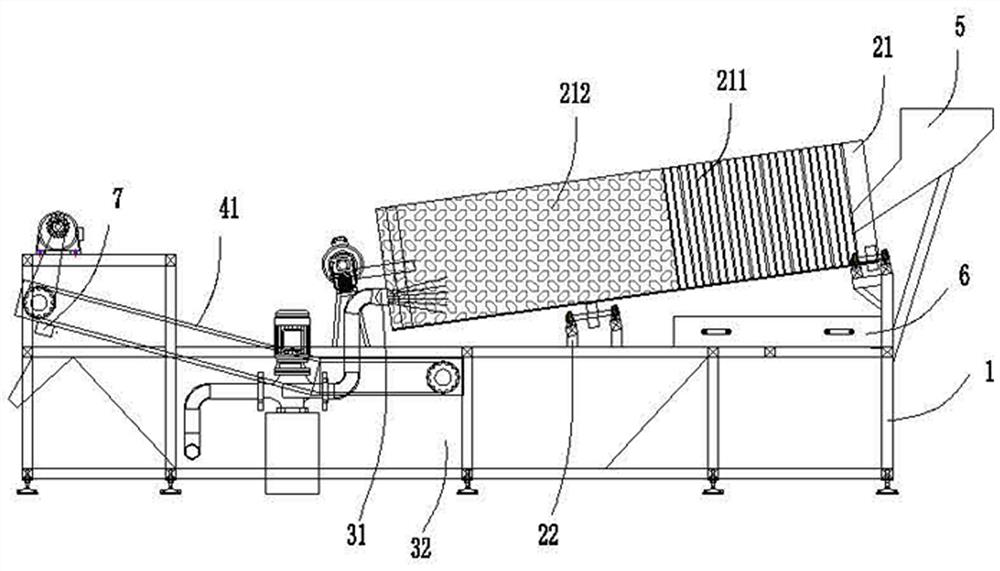

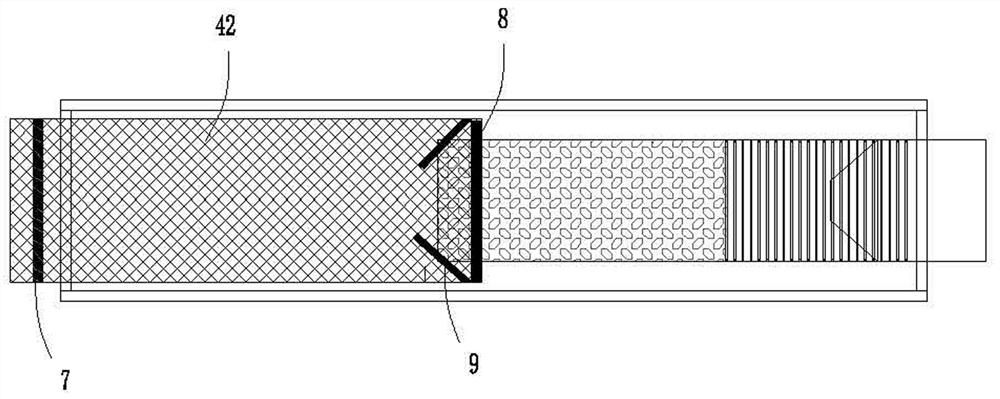

[0023] like figure 1 As shown, a cleaning machine is generally used for cleaning fruits such as camellia oleifera seeds. It includes a frame 1 and a roller device, a water supply device and a conveying device continuously arranged on the frame. The drum 21 for cleaning and the rotating mechanism 22 that drives the drum to rotate (this rotating mechanism is widely used in the prior art, such as the rotating mechanism of the concrete mixer drum), and the drum 21 is equipped with screen holes to filter out material debris and cleaning water. The water supply device includes a nozzle 31 located at the material outlet end of the drum 21 and a water tank 32 located below the drum. The nozzle 31 directly sprays cleaning water into the drum, and the water tank 32 can receive the cleaning water filtered out from the drum 21. Specifically, the nozzle 31 is close to the drum. The bottom of the drum is set, because the material is always at the bottom of the drum during the rolling proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com