Rainwater mud settling trap

A sludge well and rainwater technology, applied in water/sludge/sewage treatment, sedimentation tank, sedimentation separation, etc., can solve the problems of large rainwater flow, poor sludge effect, and high cleaning cost, and achieve high safety and structure. Simple, construction-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

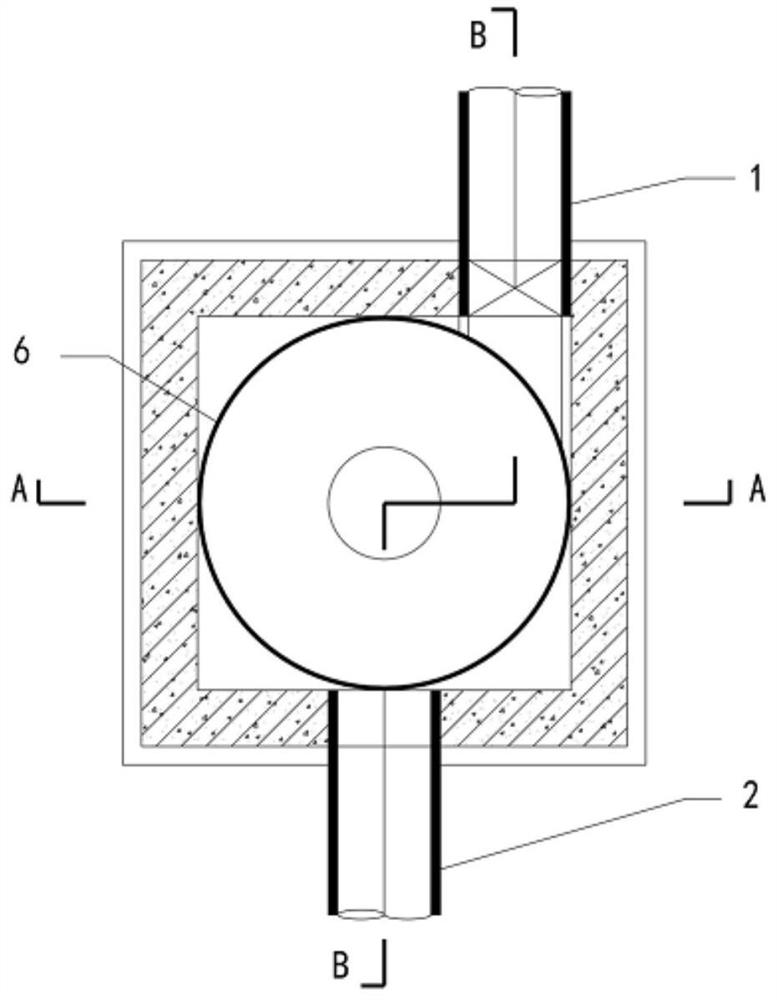

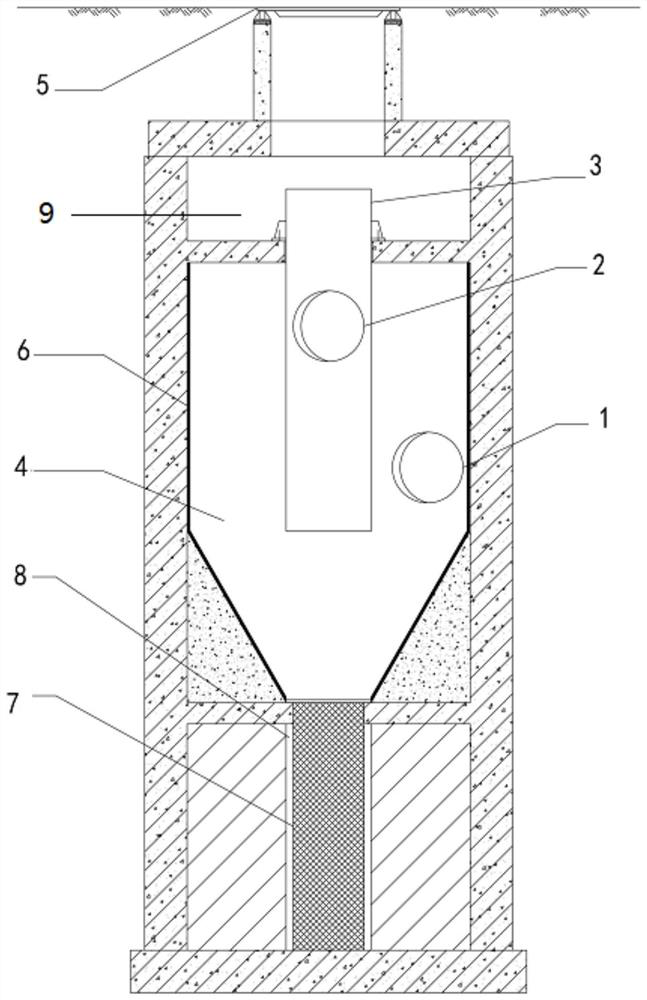

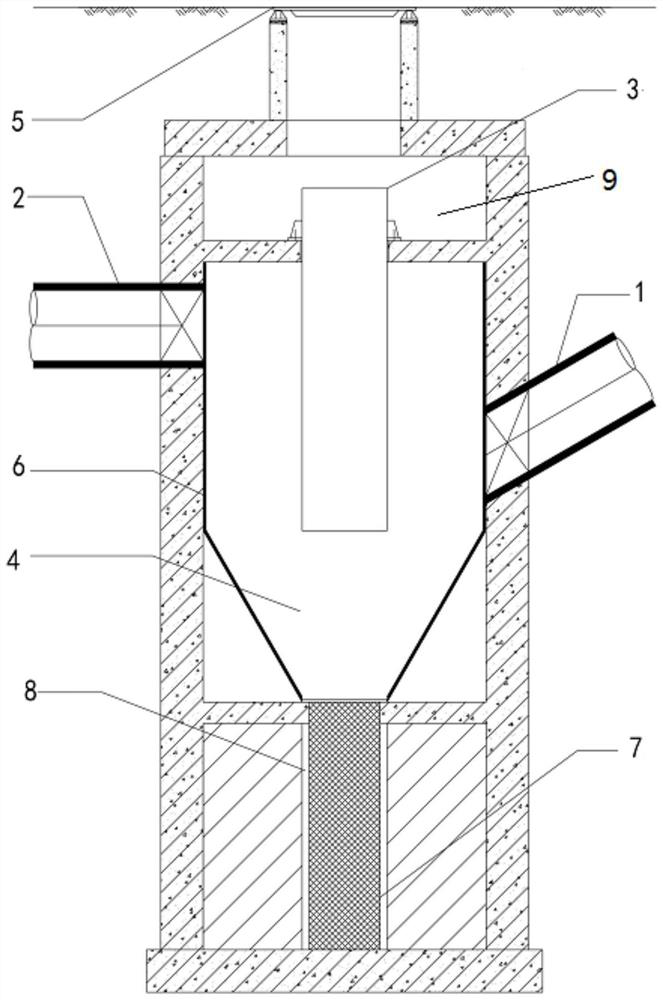

[0056] Such as Figure 1 to Figure 3 As shown, the present invention provides a kind of rainwater sedimentation well, comprising:

[0057] The sand-water separation well chamber 4, the sand-water separation well chamber 4 includes a first part and a second part, the first part is straight cylindrical, the second part is conical, and the second part is located on the lower side of the first part;

[0058] The water inlet pipe 1 is set on one side of the first part, and the water inlet pipe 1 is connected with the sand-water separation chamber 4, and the axis of the water inlet pipe 1 does not pass through the center of the first part, so that the water inlet pipe 1 enters the sand-water separation chamber 4 The water flow inside forms a swirling flow;

[0059] The water outlet pipe 2 is arranged above the water inlet pipe 2 and communicates with the sand-water separation well chamber 1;

[0060] Vent holes are arranged on the top wall of the sand-water separation well chamber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com