Middle frame of electronic equipment, manufacturing method of middle frame, shell of electronic equipment and electronic equipment

A technology of electronic equipment and production method, which is applied to branch equipment, telephone communication, electrical components, etc., can solve the problems of lowering the degree of vividness and brightness of colors, unable to achieve the brilliant effect of pink and gold, and expensive gold.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The preparation process of the first UV adhesive layer 140 includes: the pre-baking temperature is 50°C-60°C, the pre-baking time is 3min-5min; the humidity of the spray booth is 45%-70%, and the temperature of the spray booth is 18°C-25°C; The irradiation energy of the furnace is 900mj / cm 2 ~1200mj / cm 2 . The above only lists a commonly used UV adhesive layer preparation process, but is not limited thereto, and can also be a commonly used UV adhesive layer preparation process in the art.

[0054] Further, the thickness of the first UV adhesive layer 140 is 8 μm˜12 μm. In one embodiment, the thickness of the first UV adhesive layer 140 is 8 μm, 9 μm, 10 μm, 11 μm or 12 μm.

[0055] The function of the second UV adhesive layer 150 is mainly to protect the optical film layer 130 and improve the overall wear resistance of the middle frame 100 of the electronic device. The composition and preparation process of the second UV adhesive layer 150 are the same as those of t...

Embodiment 1

[0094] The manufacturing process of the middle frame of the electronic device in this embodiment is specifically as follows:

[0095] (1) Spray coating on the substrate to form a coating layer with a thickness of 16 μm. Wherein, the raw material of the paint layer is composed of paint main agent and 783 slow-drying water (thinner) with a mass ratio of 1:3. In terms of parts by mass, the paint main agent consists of 20 parts of ABS resin, 30 parts of naphthol red and silver powder (pigment) with a mass ratio of 1:1, 30 parts of 783 slow-drying water (solvent) and 2 parts of dispersant (auxiliary) portion composition.

[0096] (2) Form a first UV adhesive layer with a thickness of 12 μm on the side of the coating layer away from the substrate. The raw material of the first UV adhesive layer consists of 783 slow-drying water (thinner), photoinitiator and defoamer with a mass ratio of 50:50:2.

[0097] (3) Sputtering sequentially on the side of the first UV glue layer away from...

Embodiment 2

[0100] The manufacturing process of the middle frame of the electronic device in this embodiment is specifically as follows:

[0101] (1) Spray coating on the substrate to form a coating layer with a thickness of 16 μm. Wherein, the raw material of the paint layer is composed of paint main agent and 783 slow-drying water (thinner) with a mass ratio of 1:3. In terms of parts by mass, the paint main agent consists of 20 parts of ABS resin, 30 parts of naphthol red and silver powder (pigment) with a mass ratio of 1:1, 30 parts of 783 slow-drying water (solvent) and 2 parts of dispersant (auxiliary) portion composition.

[0102] (2) Form a first UV adhesive layer with a thickness of 12 μm on the side of the coating layer away from the substrate. The raw material of the first UV adhesive layer consists of 783 slow-drying water (thinner), photoinitiator and defoamer with a mass ratio of 50:50:2.

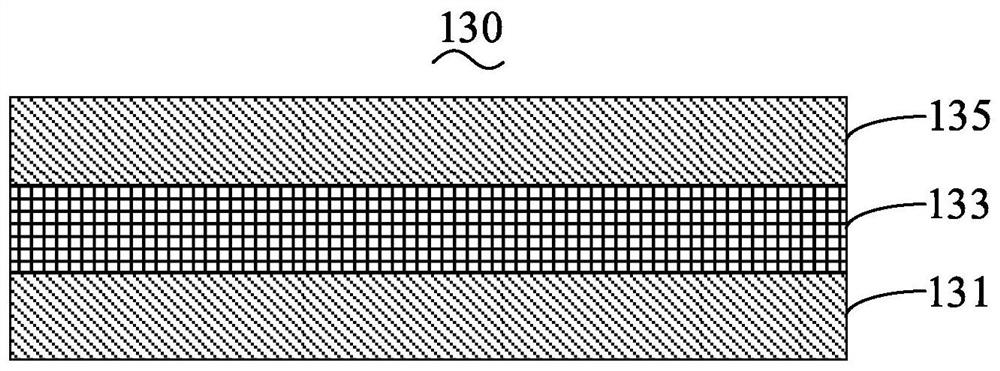

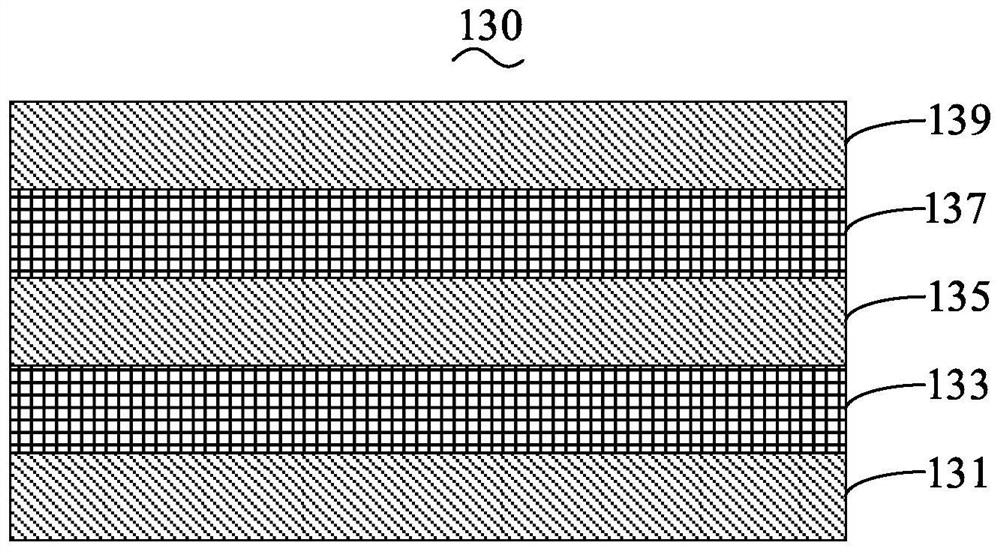

[0103] (3) Form the first high-refractive index layer, the first low-refractive-ind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com