Marine nitrogen preparation device integrating multiple functions and having safety redundancy and control method thereof

A safety redundancy and preparation device technology, applied in the direction of chemical instruments and methods, nitrogen compounds, nitrogen purification/separation, etc., can solve the problems of many coupling factors, large loss of equipment components, and large mutual influence of parameters, etc., to achieve nitrogen production process Smooth, stable pipe network pressure, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

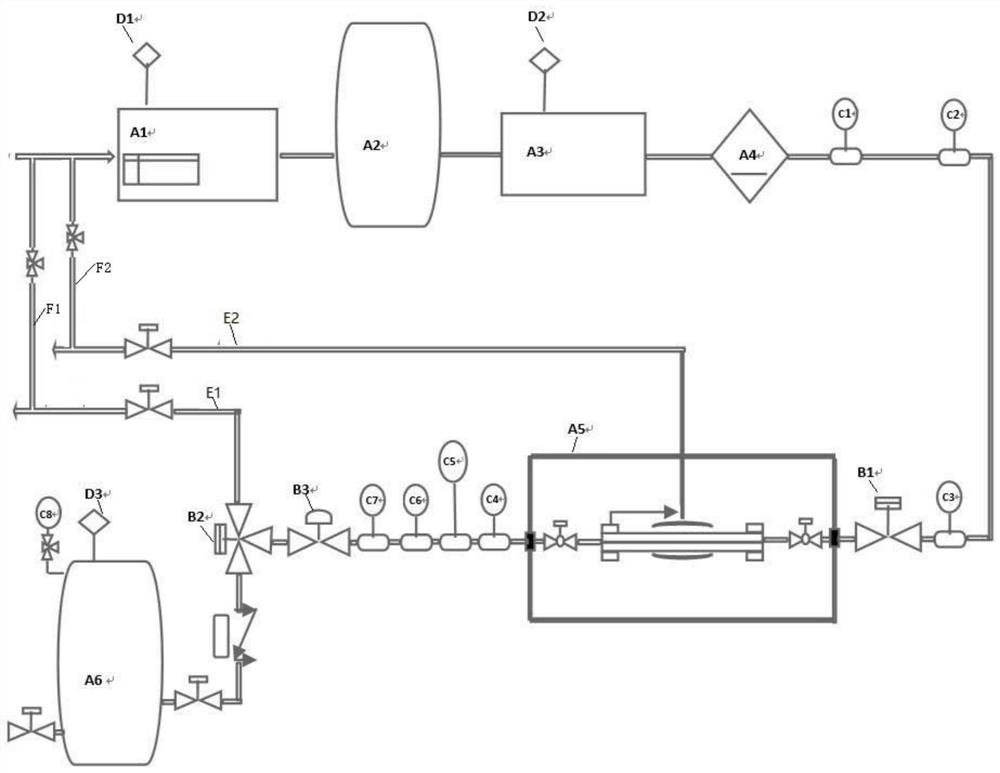

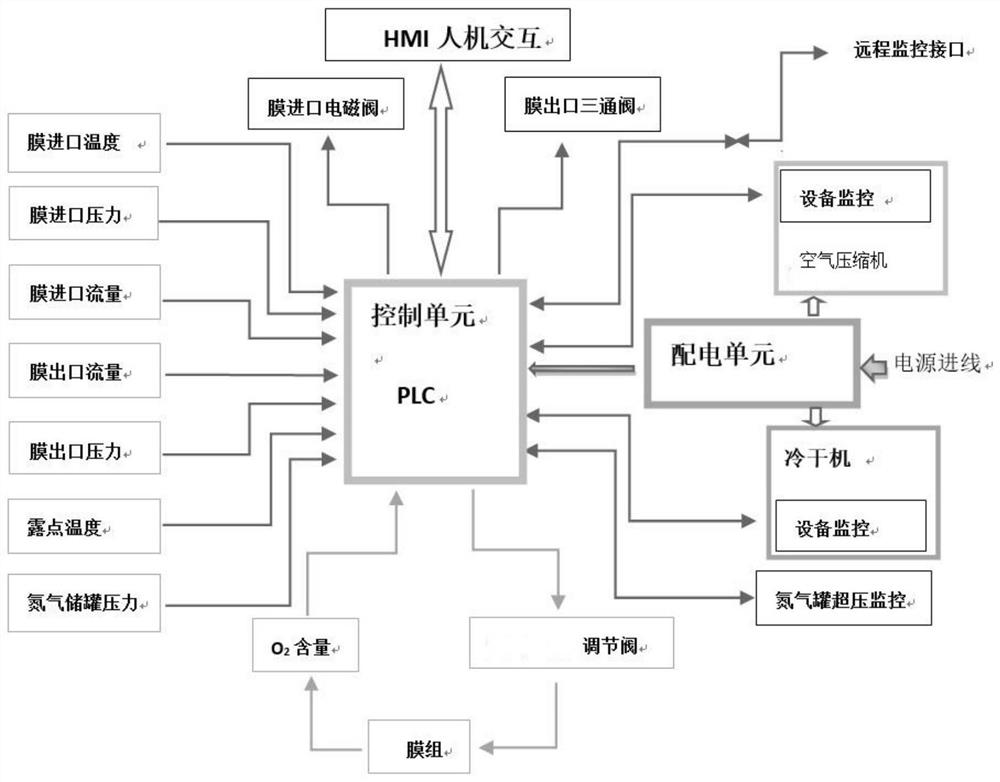

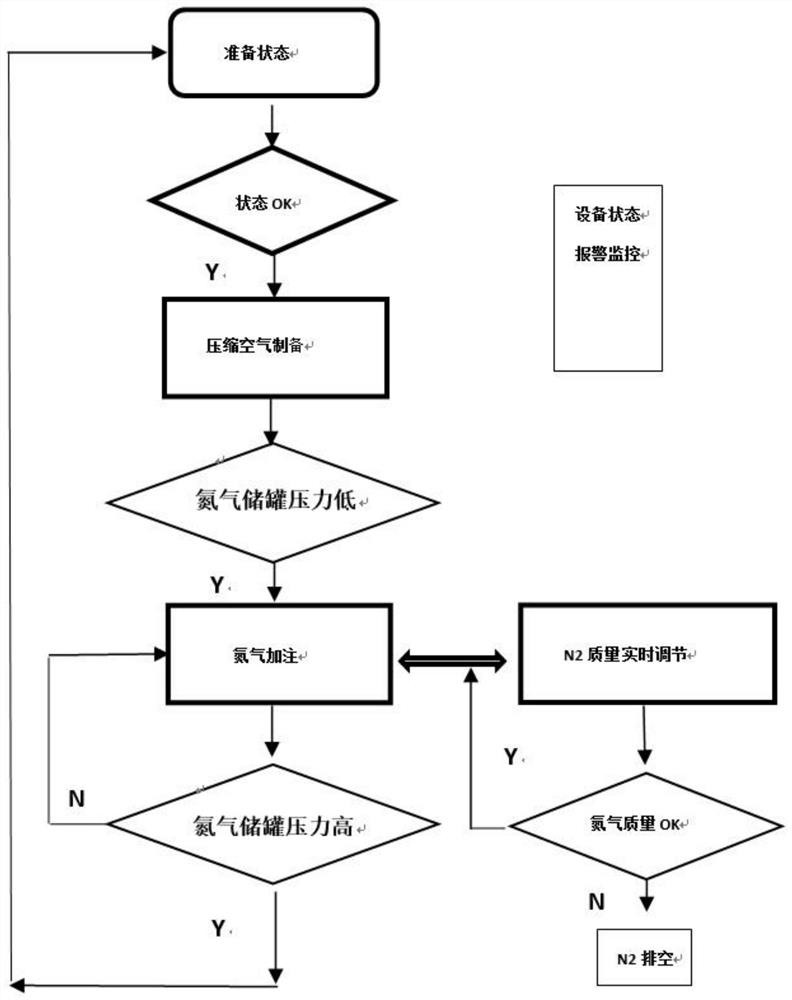

[0099] This embodiment provides a marine nitrogen preparation device with safety redundancy that integrates multiple functions, including an air compressor (A1), a compressed air storage tank (A2), a cold dryer (A3), Filter (A4), membrane inlet flow transmitter (C1), membrane inlet pressure transmitter (C2), membrane inlet temperature transmitter (C3), membrane inlet solenoid valve (B1), membrane air separation unit (A5 ), oxygen analyzer (C4), dew point temperature meter (C5), membrane outlet pressure transmitter (C6), membrane outlet flow transmitter (C7), regulating valve (B3), membrane outlet three-way valve (B2) , Nitrogen storage tank (A6);

[0100] A nitrogen storage tank pressure transmitter (C8) and a nitrogen storage tank pressure switch (D3) are installed on the nitrogen storage tank (A6);

[0101] The air compressor status switch (D1) is set on the air compressor (A1), and the freeze dryer status switch (D2) is set on the freeze dryer (A3);

[0102] The exhaust g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com