Heating adjustment device and glass thickness adjustment method

A technology for adjusting device and glass thickness, which is applied in glass forming, glass forming, glass manufacturing equipment, etc. It can solve the problems of poor thickness adjustment effect, power attenuation of platinum hot air pipe, poor thickness adjustment effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]In the present invention, in the case where it is not described, the orientation, such as "upper, lower, left, right", usually refers to the upper and lower left and right, "within, outside" in the graphical interface of the drawing. Refers to the inside and outside of the structure in the graphical interface of the drawing.

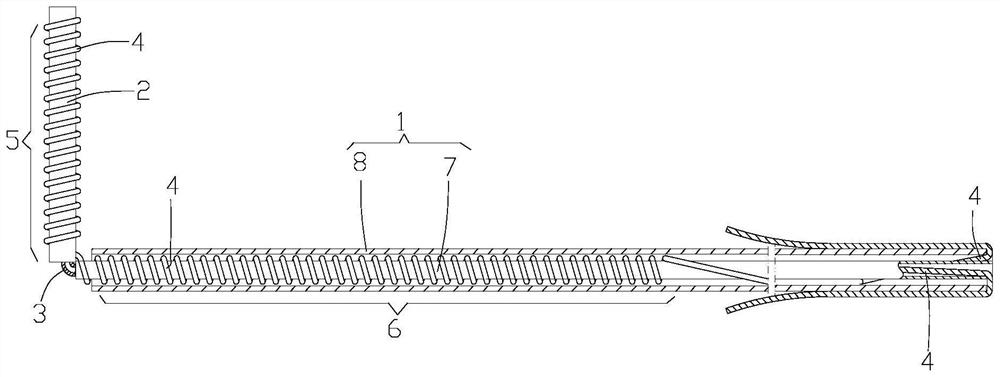

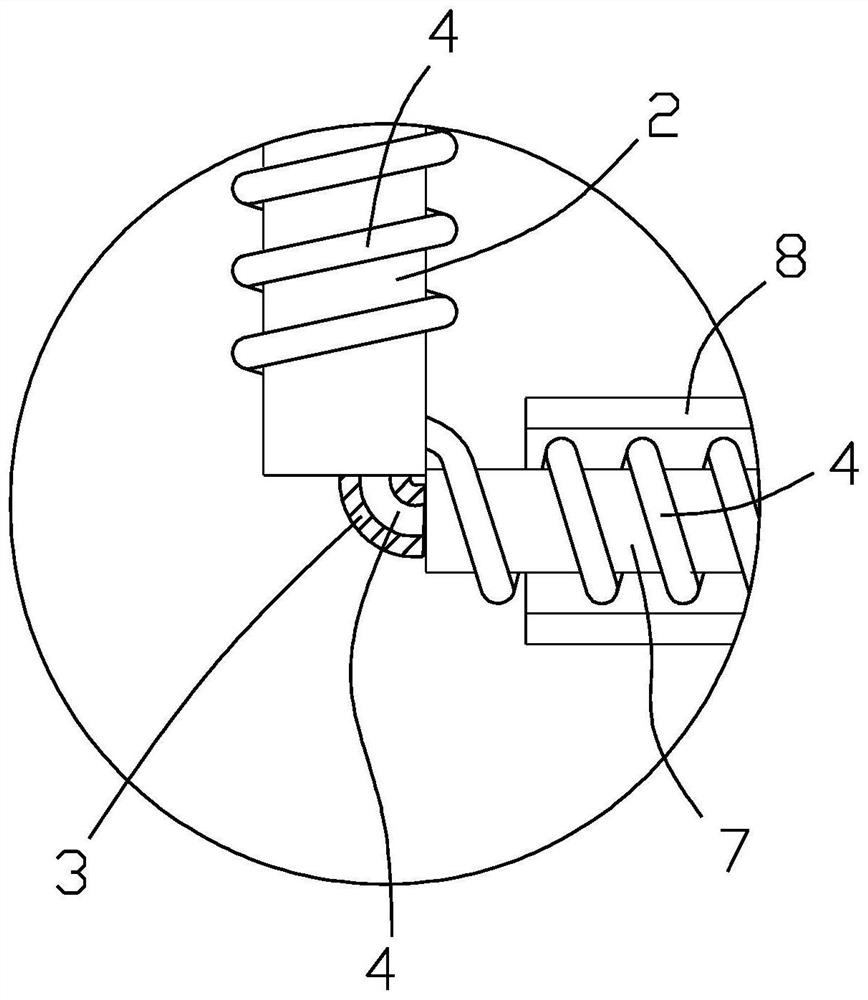

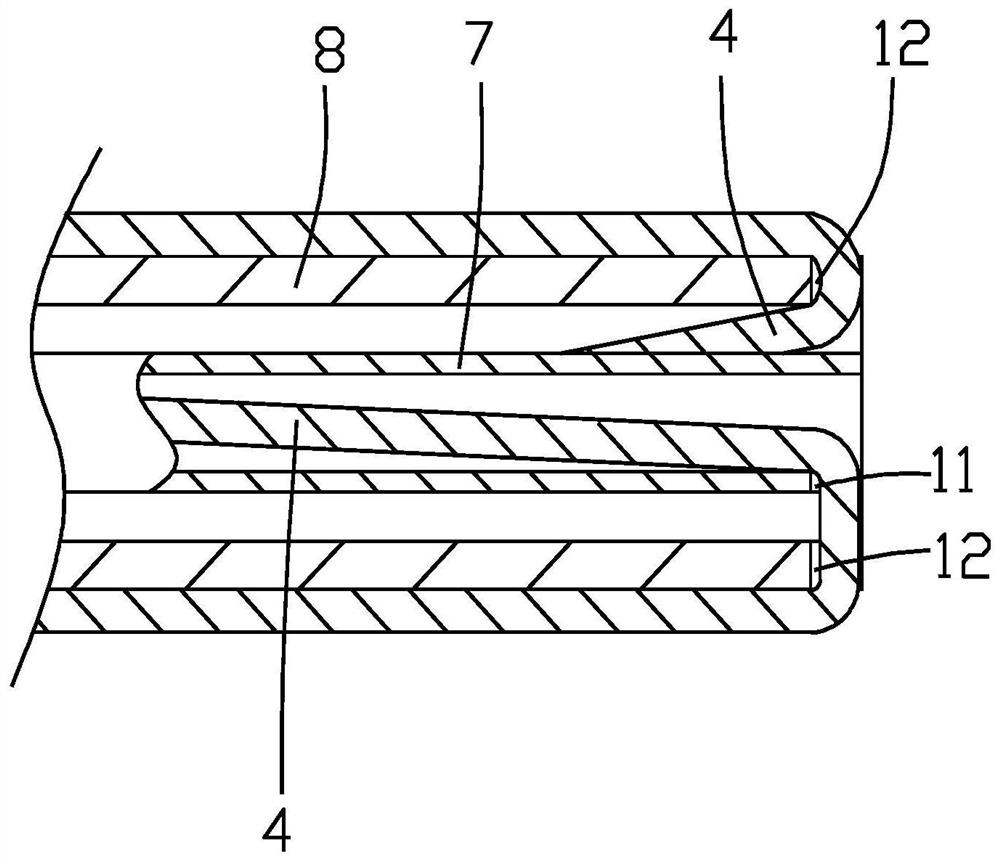

[0033]referencefigure 1 ,figure 2 ,image 3 withFigure 4The heating adjustment device provided by the present invention includes a first insulating tube section 1, a second insulating tube section 2, an insulating structure 3, and an electric heating wire 4, wherein the first insulating tube section 1 has a first internal passage, and the second insulating tube section 2 Has a second internal passage; there is a through passage in the insulating structure 3, and the insulating structure 3 is disposed between the first insulating tube segment 1 and the second insulating tube segment 2; the electric heating wire 4 is penetrated into the first internal passage....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com