Dividing and cutting machine with straight knife dividing and cutting mechanism and using method of dividing and cutting machine

A slitting machine and base technology, which is applied in the direction of sending objects, thin material processing, transportation and packaging, etc., can solve the problems of burrs on slitting edges, long time for knife arrangement, and inconvenient practicability, and achieve fast loading and unloading, accurate card buckle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

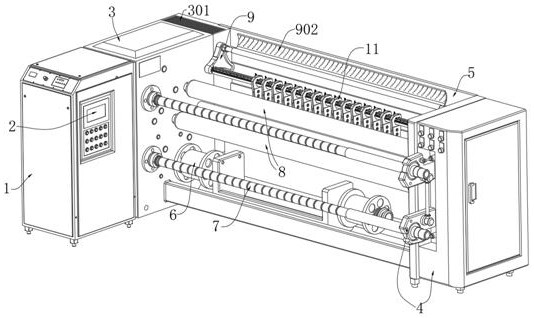

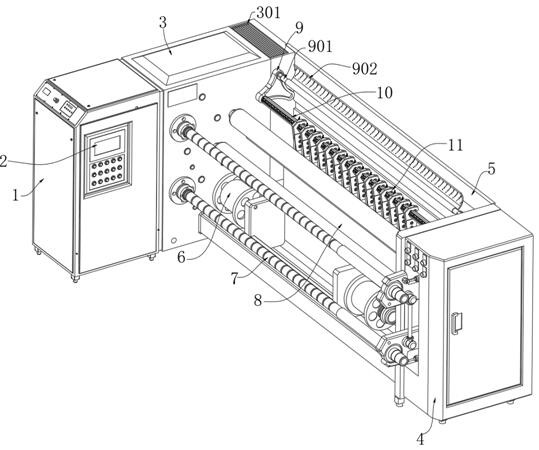

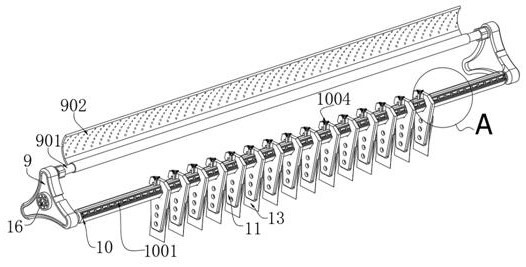

[0031] see Figure 1-7 , the present invention provides a technical solution: a slitting machine with a straight knife slitting mechanism, including a power distribution cabinet 1, fifteen knife bases 11 and two mutually symmetrical triangular plates 9, the power distribution cabinet 1 A controller 2 is installed on the inner side wall of the power distribution cabinet 1, and the rear surface of the power distribution cabinet 1 is connected with a sliding board box 3 through screws, and one side of the sliding board box 3 is fixedly connected with a material storage roller 6 through a coupling, and the sliding board box 3 One side is fixedly connected with two connecting rollers 7 through a shaft coupling, the rear surface of the slide box 3 is welded with a connecting plate 5, the front surface of the connecting plate 5 is welded with a box body 4, and the outer surface of the connecting roller 7 is connected with the box body 4. Compatible with the outer wall of the

[0032...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com