Device for eliminating bubble vibration for casting mold

A technology of air bubble elimination and vibration device, which is applied in the field of casting molds, can solve the problems of casting products with air bubbles, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

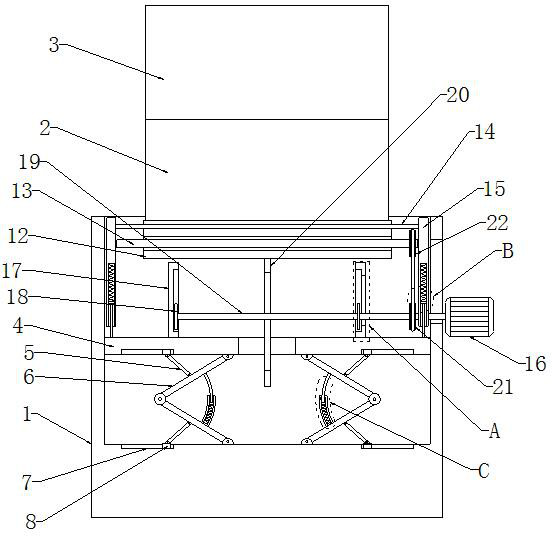

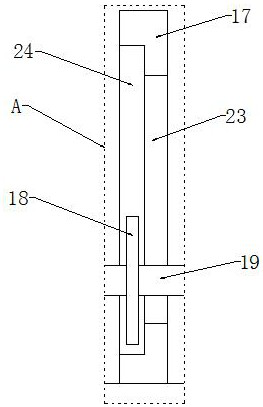

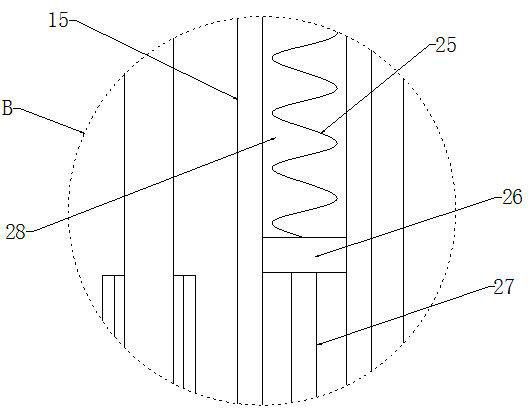

[0027] refer to Figure 1-3 and Figure 5-6 , a kind of air bubble elimination vibration device for casting mould, comprising upper mold 3, lower mold 2, bottom plate 12 and vibrating base 1, upper mold 3 and lower mold 2 are spliced and arranged, and the bottom end of lower mold 2 is fixedly connected with bottom plate 12, The vibrating base 1 is arranged in a U-shaped structure, and a horizontal damping plate 4 is slidably installed between the inner walls of both sides of the vibrating base 1, and the top of the damping plate 4 is fixedly connected with two symmetrically distributed fixed plates 17, and The sides of the two fixed plates 17 that are close to each other are provided with tooth grooves 24, and the movable plates 15 that are symmetrically distributed are slidably installed between the inner walls of both sides of the vibrating base 1, and the two movable plates 15 are located between the two fixed plates 17. On the far side, a reciprocating screw rod 13 is r...

Embodiment 2

[0034] refer to figure 1 and Figure 4 , this embodiment adds the specific structure and specific implementation of the shock absorbing mechanism, and effectively buffers and protects the casting mold. A shock absorbing mechanism is arranged between the bottom end of the shock absorbing plate 4 and the bottom inner wall of the vibrating base 1 , and the damping mechanism includes a hinged rod 5, a damping rod 6, a chute 7, a slider 8, a sleeve 9, a movable rod 10 and a damping spring 11, the bottom end of the damping plate 4 and the bottom end of the vibration base 1 There are two groups of symmetrically distributed damping rods 6 hinged between the inner walls, and the two damping rods 6 on the same side are hinged to each other, and the two damping rods 6 on the same side are hinged on the side far away from each other. 5, and the end of the hinge rod 5 away from the damping rod 6 is hinged with a slider 8, and two groups of symmetrically distributed chute 7 are arranged be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com