Wind turbine pitch motor temperature sensor fault warning method based on lightgbm algorithm

A temperature sensor, pitch motor technology, applied in computer-aided design, instrumentation, calculation, etc., can solve the problems of low accuracy, difficulty in early warning modeling, etc., and achieve the effect of solving modeling difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to make the purpose, technical solutions and advantages of the present invention clearer, the technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

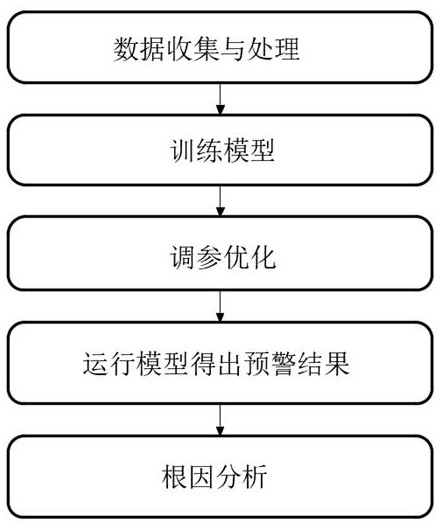

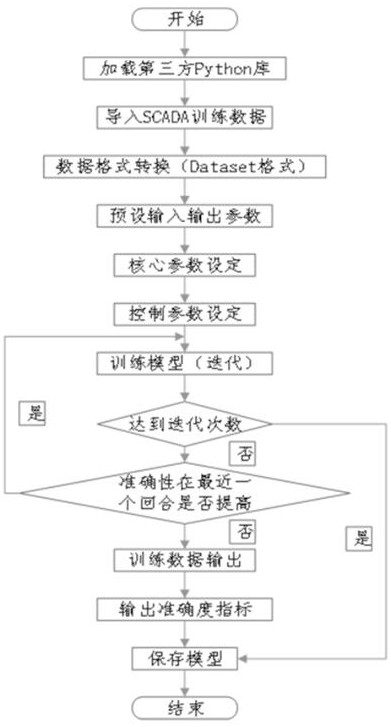

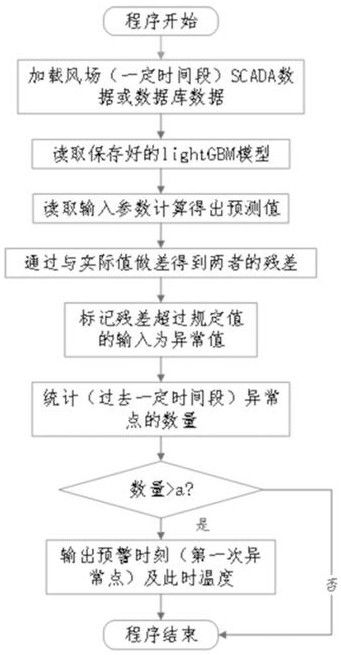

[0059] Such as Figure 1-5 As shown, the wind turbine pitch motor temperature sensor fault warning method based on the LightGBM algorithm includes the following steps:

[0060] Step S1: Data collection and processing, collecting enough wind turbine operation data before modeling, and performing preliminary processing;

[0061] In this step, the wind turbine operation data includes the SCADA historical operation data of the wind turbine in the time period T, and the telemetry signal related to the temperature of the pitch motor in the SCADA data is specifically selected, and the abnormal data is eliminated according to the IEC standard.

[0062] Step S2: Train the model, select the data with the fault of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com