A hot air internal circulation type tea-milling stove and drying method thereof

A technology of hot air internal circulation and tea stove, which is applied in drying, drying machine, tea drying, etc. It can solve the problems of non-drying treatment, long drying time, and unsatisfactory drying effect, so as to ensure the drying effect, Guarantee drying efficiency and avoid the effect of product taste deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

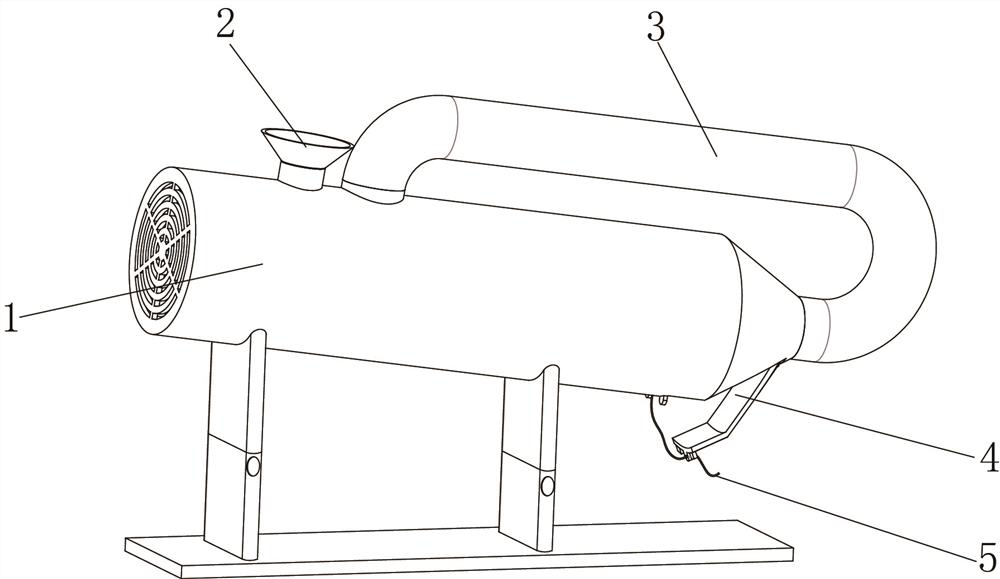

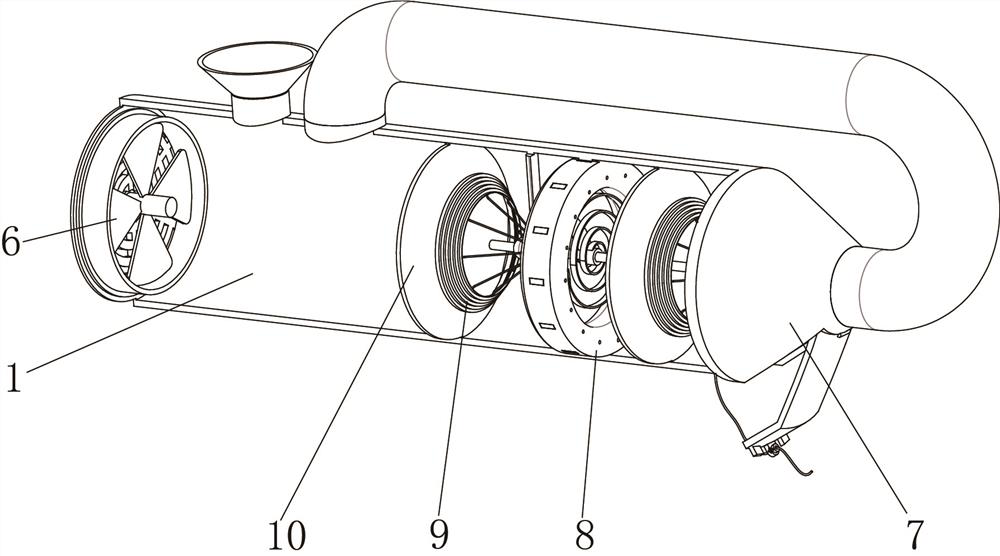

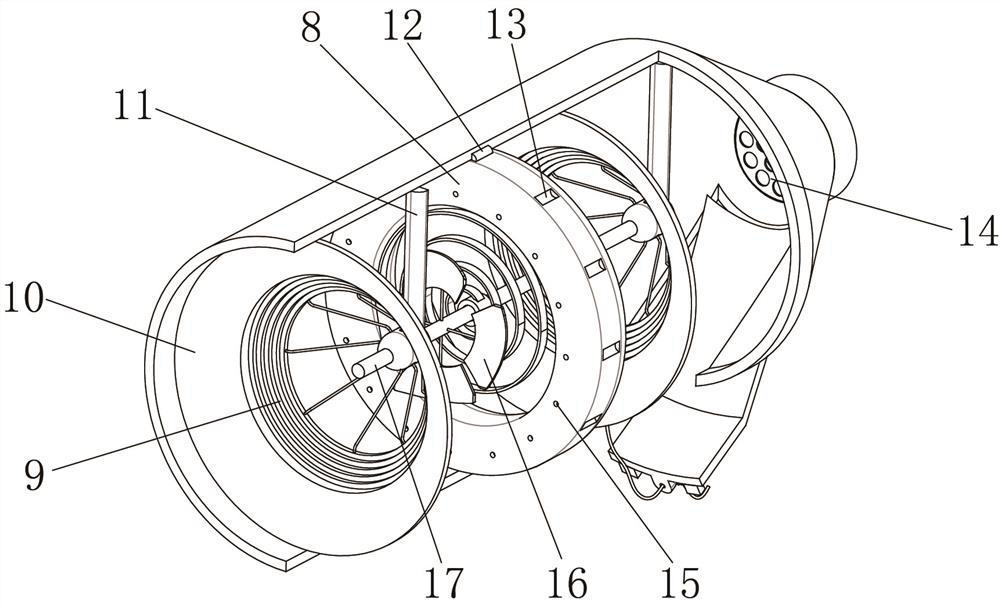

[0043] A kind of hot air internal circulation type tea mill, such as Figure 1-8 As shown, it includes a furnace body 1, the bottom of the furnace body 1 is provided with an adjustable support frame, one end of the furnace body 1 is integrally provided with a gathering bucket 7, and the outer wall of the bottom of the gathering bucket 7 is connected with a discharge door 4 through a hinge. 1. A drying fan 6 is installed on the inner wall of one end through the fan seat, and the furnace body 1 is installed at an inclination as a whole. The level of the discharge door 4 is lower than that of the drying fan 6. The inner wall of the top of the furnace body 1 is detachable by screws. More than two installation frames 11 are installed, and the outer wall of the bottom of the installation frame 11 is rotatably installed with the same rotating main shaft 17, and more than two confluence mechanisms are arranged on the outside of the circumference of the rotating main shaft 17, and the i...

Embodiment 2

[0052] A kind of drying method of the hot air internal circulation type tea milling stove, such as Figure 1-9 shown, including the following steps:

[0053] S1: adjust the inclination angle of the furnace body 1;

[0054] S2: adjust the effective length of the elastic cord 5 through the fixed knob 31;

[0055] S3: Control the operation of the drying fan 6 to preheat the furnace body 1;

[0056] S4: Add tencha to be dried into the feeding port 2;

[0057] S5: Tencha passes through various confluence mechanisms, is fully dried by hot air, and then is automatically unloaded from the discharge door 4;

[0058] S6: Collect the tencha, and after drying, open the discharge door 4 to collect the remaining tencha.

[0059] In order to ensure the taste of the product; Figure 9 As shown, in the S1 step, the angle between the furnace body 1 and the horizontal plane is controlled at 15-40°, even 25°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com