Multi-layer flat tube bag rapid dehydration system and dehydration method for mud treatment

A rapid dehydration, tube bag technology, applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of slow water discharge, increased construction period, small osmotic gradient, etc. Drainage rate, effect of accelerating soil consolidation, increasing drainage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. The protection scope of the present invention is not limited by the specific embodiments, but by the claims.

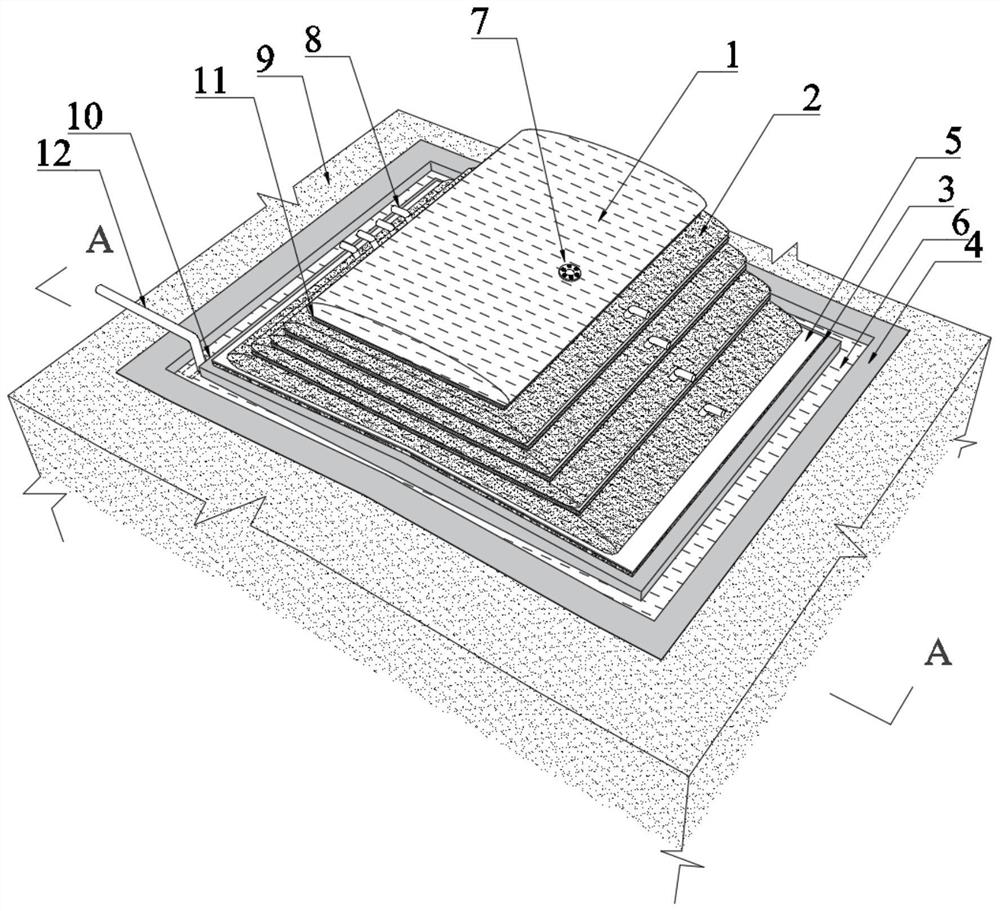

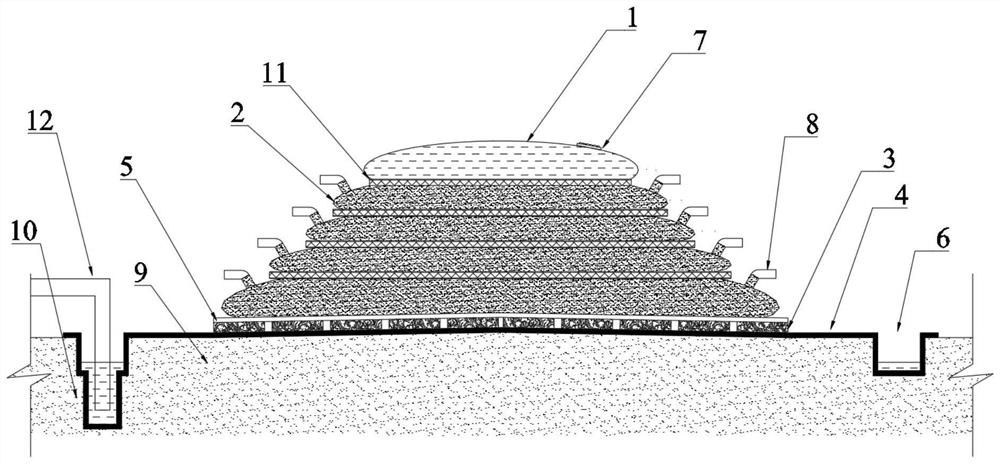

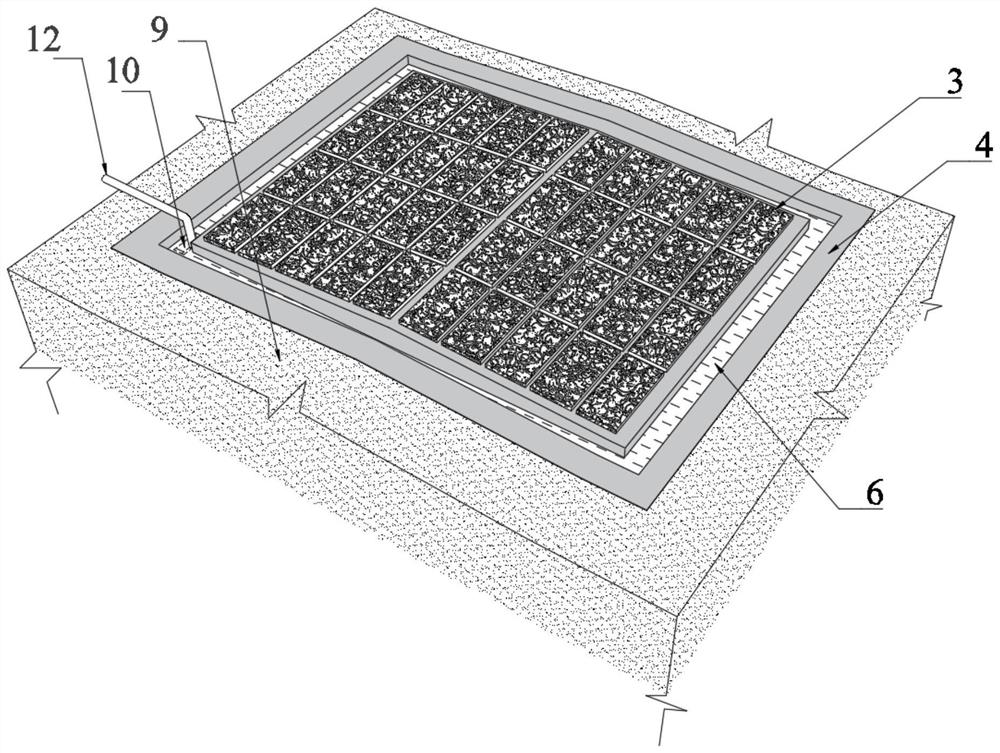

[0039] Such as Figure 1~Figure 2 As shown, a multi-layer flat pipe bag rapid dehydration system for mud treatment consists of a ballast water bag 1, a flat geotechnical pipe bag 2, a bottom water guide layer 3, an anti-seepage layer 4, a protective cushion layer 5, a drainage platform, The interlayer water guide layer 11 and the pumping pipeline 12 are composed. The drainage platform includes a sump 6 , an inclined base layer 9 and a sump well 10 . The main structure of the system from top to bottom is the ballasted water bladder, multiple interlayer water guide layers and pipe bag stacks, protective cushion, bottom water guide layer, anti-seepage layer, and sump.

[0040] A ballast water bag 1 is arranged above the pipe bag 2, whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com