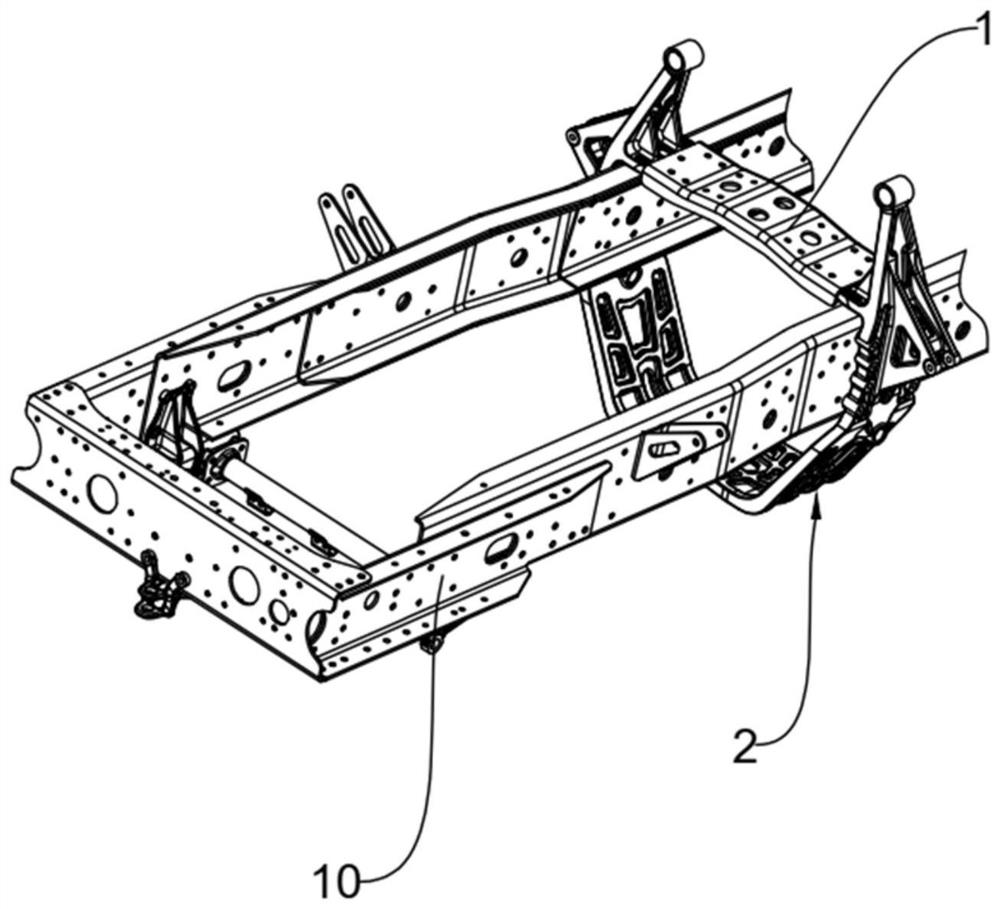

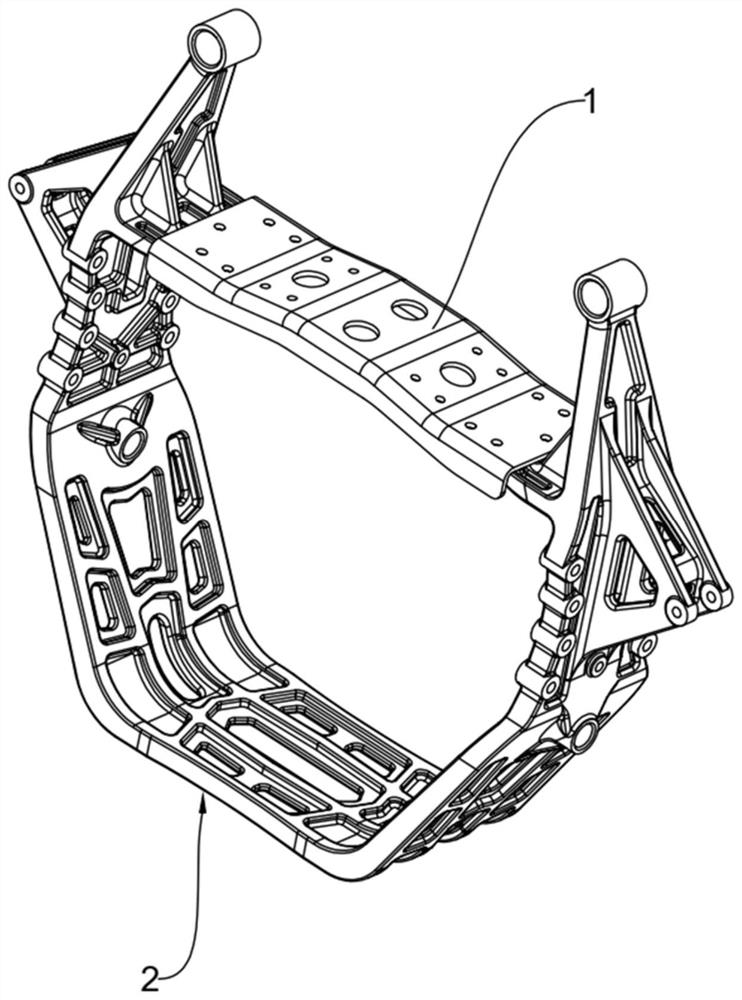

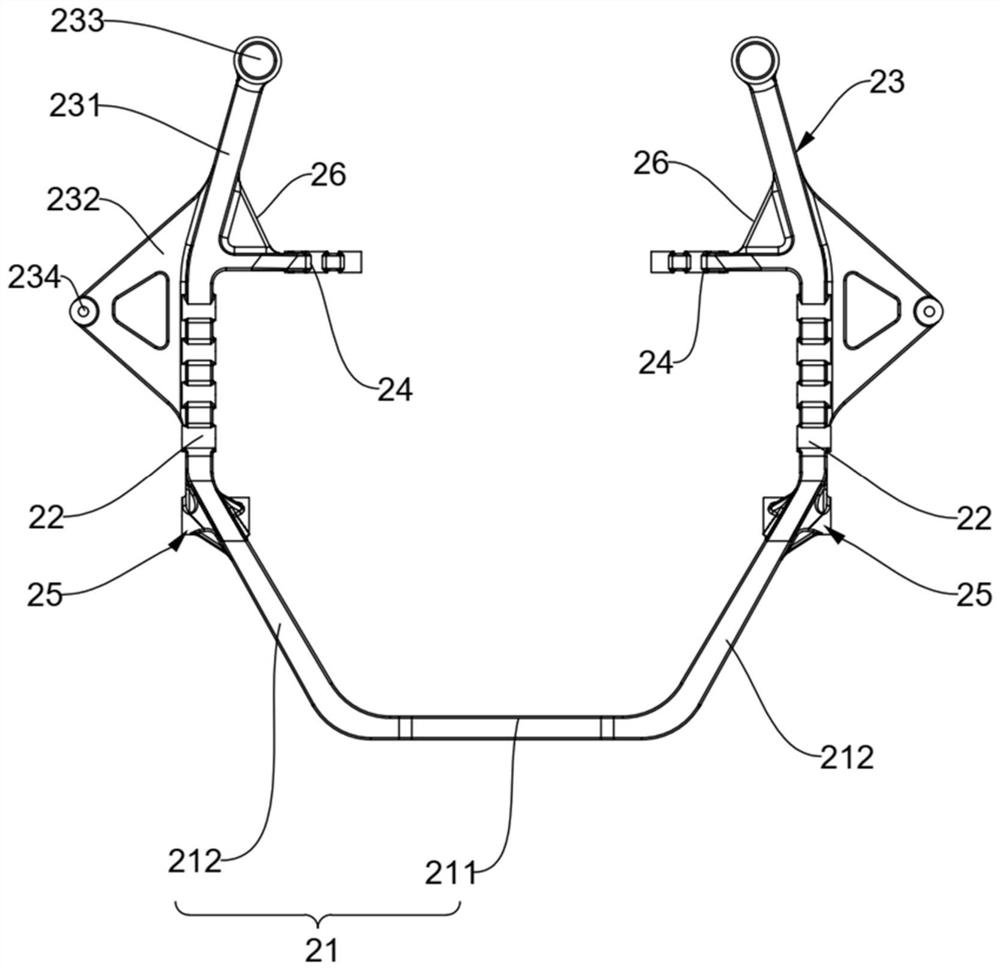

A beam assembly

A beam assembly and beam technology, applied in the field of auto parts, can solve the problems of high cost of large stamping dies, difficulty in ensuring the accuracy of the outer width of the frame due to production dimensional errors, and complex shapes of the beams of the front springs and rear brackets. The effect of stability, improving product dimensional accuracy, and reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only the parts related to the present invention are shown in the drawings but not all of them.

[0046] Some orientation words are limited in the present invention, and under the situation of not making contrary description, the orientation words used are as " upper ", " lower ", " left ", " right ", " inner ", " outer " these orientation words It is adopted for easy understanding, and thus does not constitute a limitation to the protection scope of the present invention.

[0047] In the present invention, unless otherwise clearly specified and limited, a first feature bein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com