Safety device and method for coil loading and unloading process

A safety device, the top-level technology, is applied in the field of safety devices in the process of loading and unloading, which can solve the problems of potential safety hazards and inconvenient operation of the trolley, and achieve the effect of ensuring safety protection and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

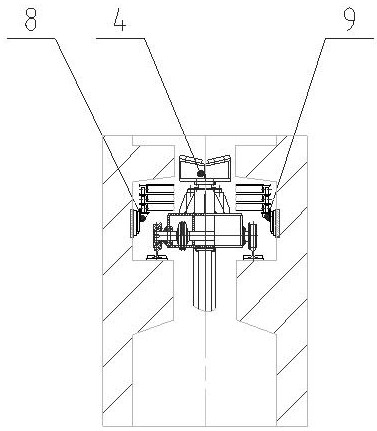

[0021] In order to overcome the problems of inconvenient operation of the trolley and potential safety hazards, the present invention provides such Figure 1-2 Shown is a safety device and method for the process of loading and unloading rolls. The present invention is simple in structure, strong in practicability, and easy to implement.

[0022] A safety device for the process of loading and unloading coils, comprising a left track surface assembly 8 and a right track surface assembly 9, a trolley 4, a rear side plank and a front side plank, the left track surface assembly 8 and the right track surface The assembly 9 is arranged symmetrically with respect to the trolley 4, and is respectively installed on the foundation walls on both sides of the trolley 4; All are multi-layer, and the bottom rear deck and the bottom front deck are rolled on the left track surface assembly 8 and the right track surface assembly 9 by rollers; the uppermost rear deck and the uppermost front deck...

Embodiment 2

[0025] Based on the basis of Example 1, in this embodiment, preferably, both ends of the upper surface of the rear side plank of the lowermost layer and the rear side plank of the middle layer are provided with limit baffles; Limiting baffles are also provided at both ends of the upper surface of the front side plank of the middle layer.

[0026] In the present invention, both the rear deck and the front deck can be made of Q235 steel to save costs and ensure that people can stand on the deck without bending the deck.

[0027] Preferably, anti-collision blocks are provided at each of the limit baffles.

[0028] Preferably, the anti-collision block is rubber.

[0029] In the present invention, the rubber anti-collision block is selected to ensure that each plank will not cause damage to the plank itself when it is in the limit position, and the service life of the present invention is improved. The anti-collision block can be made of various materials that can buffer force, n...

Embodiment 3

[0036] Based on the basis of Example 1, in this embodiment, preferably, the front side decking is three layers, including the front side upper decking board 5, the front side middle decking board 6 and the front side lower decking board 7; The lengths of the upper plank 5 and the front lower plank 7 are all less than the length of the front middle plank 6 .

[0037] Preferably, the rear decking is three layers, including the rear lower decking 1, the rear middle decking 2 and the rear upper decking 3, the rear lower decking 1, the rear middle decking 2 and the rear upper deck The planks 3 have the same length.

[0038] Such as figure 1 with figure 2 As shown, the front side lower floor plank 7 and the rear side lower floor plank 1 run on the left track surface assembly 8 and the right track surface assembly 9 by rollers; the front side middle floor plank 6 runs on the front side lower floor plank 7 and passes through the front The position is locked by the mechanical limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com