Pulse magnetic shock catapult

A catapult, pulse magnetic technology, applied in the direction of launch/drag transmission, etc., can solve the problems of difficult application of electromagnetic catapult, high technical difficulty, harsh power, etc., to reduce brush consumption, low technical difficulty, and reduce pulse effect of magnitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

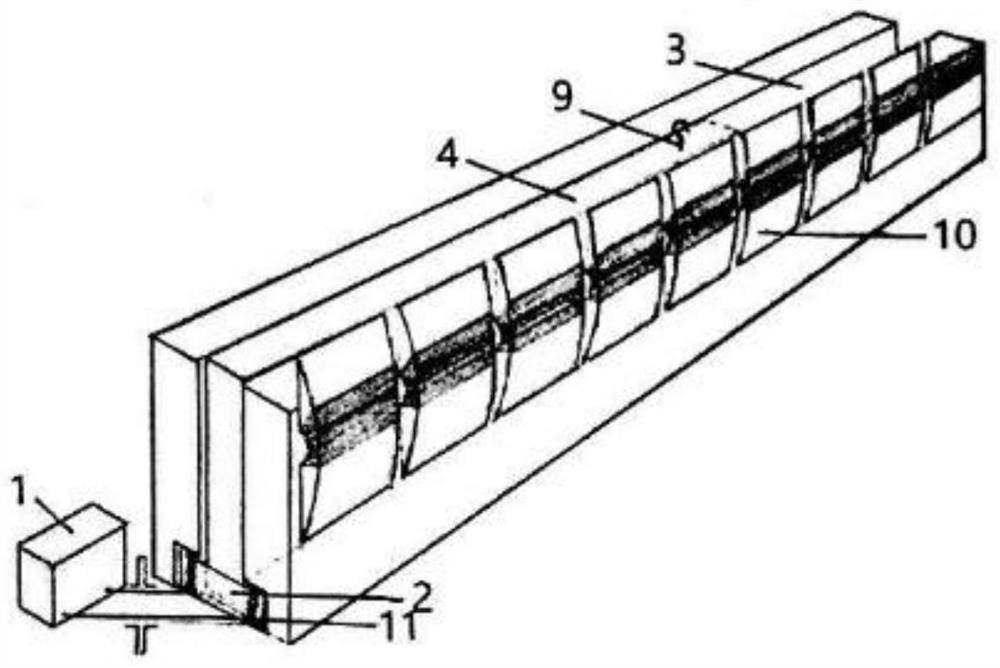

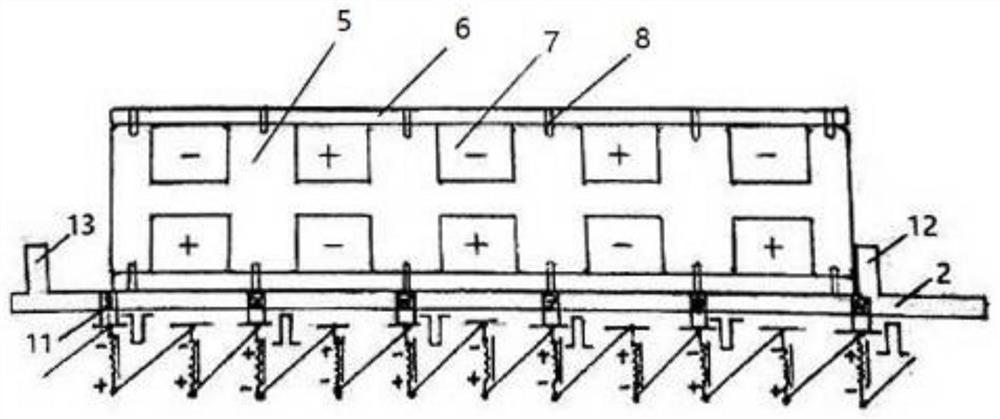

[0033] Embodiment: A kind of pulse magnetic shock catapult for aircraft carrier

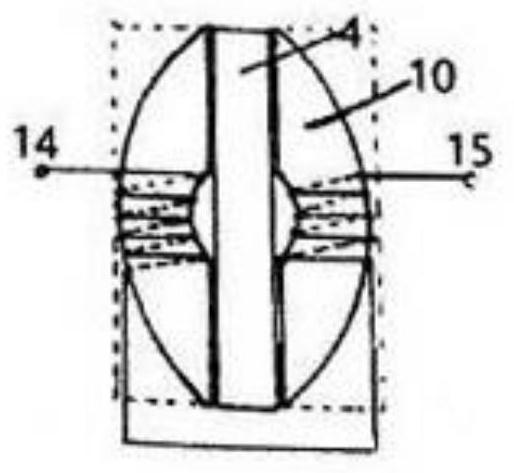

[0034] A kind of pulse magnetic shock catapult used for carrier-based aircraft as shown in accompanying drawing, 2, 3, is arranged on the second half of the skid deck of aircraft carrier, comprises power supply 1, the power supply control panel 2 that is connected with power supply 1, and The U-shaped ejection guide rail 3 connected to the power supply control board 2, and the ejection tractor 4 arranged on the U-shaped ejection guide rail 3 and slidingly connected with the U-shaped ejection guide rail 3, the U-shaped ejection guide rail 3 and the ejection tractor 4 form a high thrust density The linear propulsion device, the carrier-based aircraft waiting for ejection straddles the U-shaped ejection guide rail 3. The front end of the power supply control board 2 is provided with an ejection lock pile 12, which is used to limit the farthest position of the ejection retractor 4 sliding to the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com