Crimping type wiring terminal and use method thereof

A terminal and crimping technology, applied in the field of crimping terminals, can solve the problems of inability to meet space requirements, low reliability, and high cost, achieve a high degree of functional integration of parts, meet the requirements of space limitations, and use Convenient and fast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

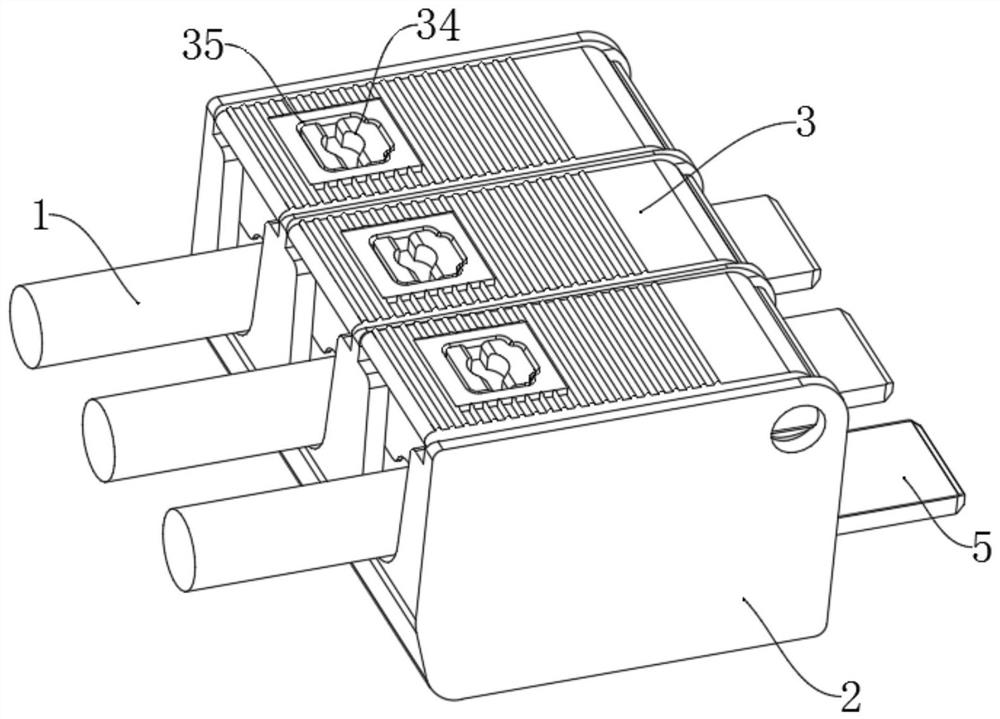

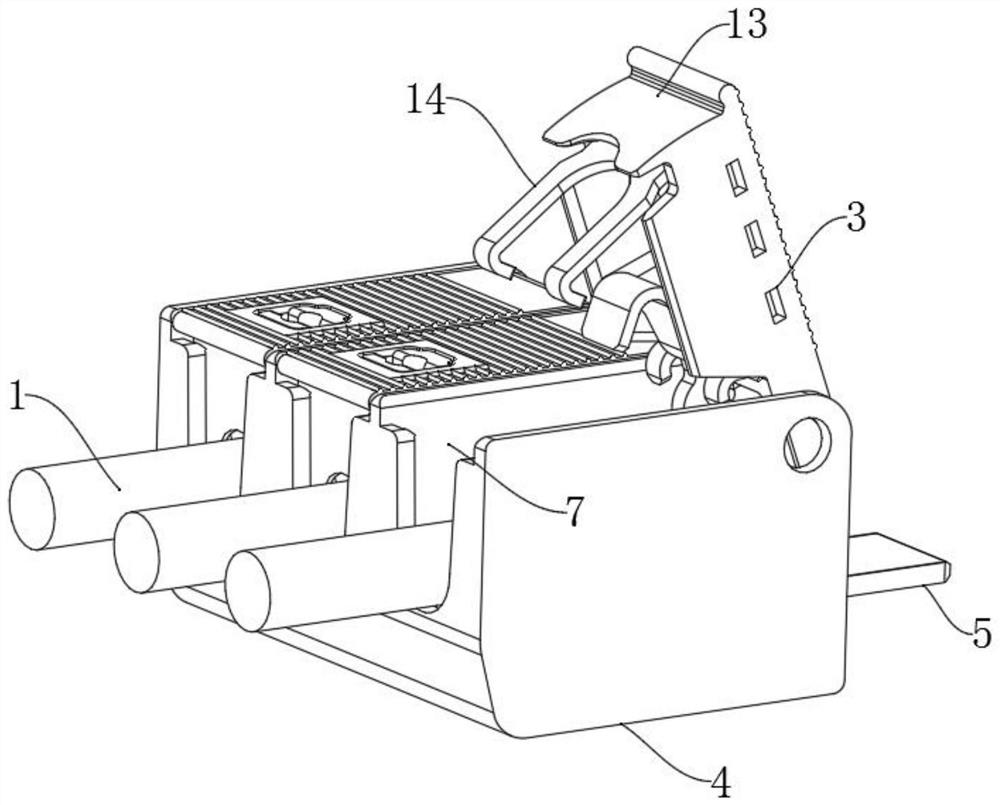

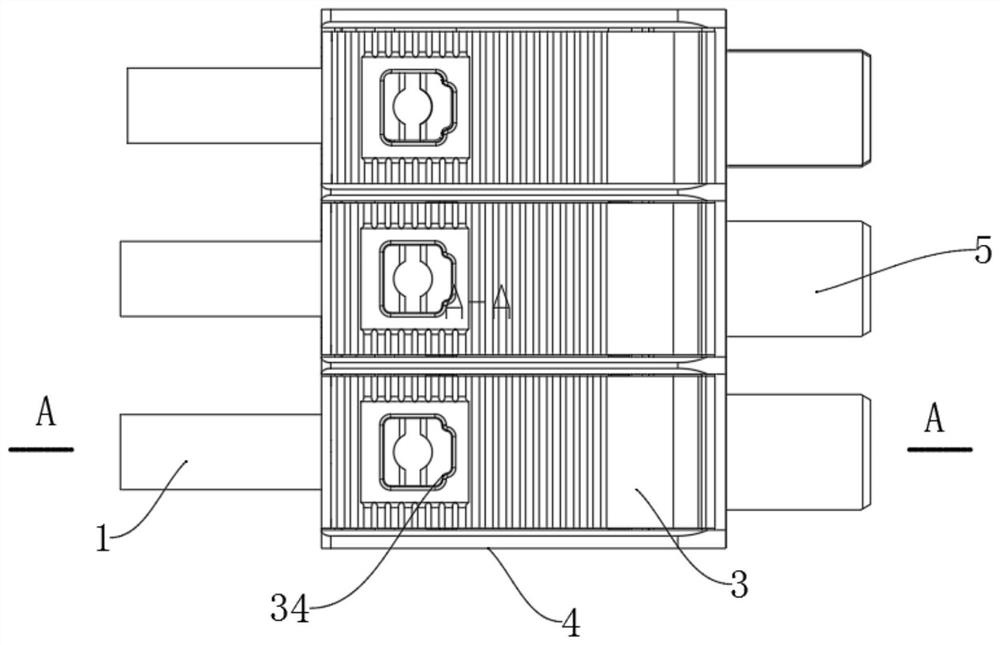

[0066] The invention discloses a crimping type terminal, comprising a base part 2 for installing a wire 1 and a pressing part 3 connected to the base part 2 for pressing the wire 1 on the base part 2; The seat part 2 includes an insulating base 4, a conductive sheet 5 and an end cover 6. The insulating base 4 is provided with at least one installation position 7, and the left end of the installation position 7 is an incoming line end; the installation position 7 is equipped with the conductive sheet 5. The end cover 6 and the pressing part 3, the conductive sheet 5 is fixedly installed in the installation position 7 through the end cover 6, the pressing part 3 is located above the conductive sheet 5 and is hingedly installed in the installation position 7; The tightening part 3 can be engaged with the conductive sheet 5 after being rotated, and the pressing part 3 and the conductive sheet 5 are engaged with each other to press the wire 1 tightly on the conductive sheet 5 .

[...

Embodiment 2

[0092] This embodiment is further optimized on the basis of Embodiment 1. In this embodiment, the pressing part 3 also includes a push block 34, the protective cover 13 is provided with a first push block groove 35, and the horizontal part 15 of the elastic piece 14 A second push block groove 36 is arranged at a position corresponding to the first push block groove 35, and the push block 34 is slidably installed in the first push block groove 35;

[0093]The mounting groove 27 is provided with a protruding bar 37 that can extend into the second push block groove 36; the side wall of the push block 34 is provided with a limit boss 38, and the limit boss 38 has a guide slope, and the push block 34 is slidably installed on the second push block. Once inside the push block groove 35 , the limiting boss 38 on the push block 34 is engaged with the protruding strip 37 ;

[0094] For further optimization, anti-slip lines 39 are provided on the upper end surface of the protective cover...

Embodiment 3

[0100] This embodiment is basically similar to Embodiment 1 or Embodiment 2, the difference is that the first horizontal portion 23 is bent at a right angle, and the bottom of the end cover 6 is provided with a vertical through groove 40 communicating with the positioning groove 9 , the first horizontal portion 23 can pass through the through slot 40 after being bent.

[0101] In order to adapt to different space requirements, one of the tails of the conductive sheet 5 is set to be bent, and the other is set to be not bent, which can be produced by replacing inserts with the same pair of molds. For the end cap 6, only the local features are changed, and the production of inserts can also be replaced by the same secondary mold. In this way, it not only satisfies product changes, but also reduces the mold cost to the greatest extent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com