Two-step reaction model calculation method for fuel detonation combustion

A reaction model, fuel detonation technology, applied in the field of aerospace, can solve problems that limit the wide application of two-step reaction models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

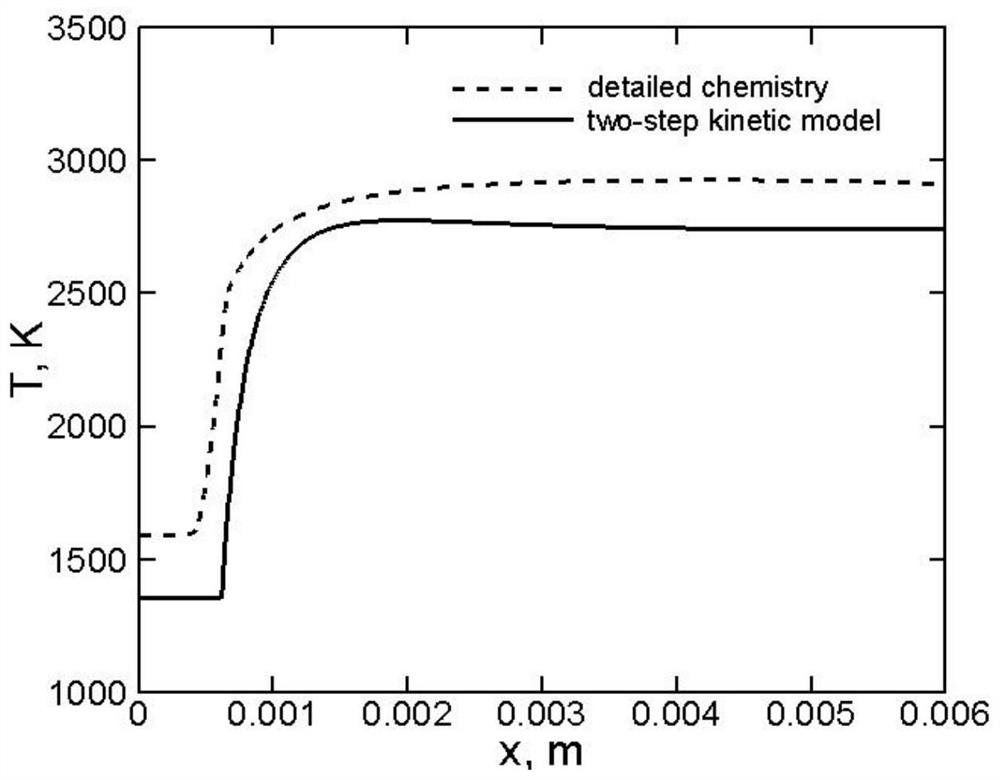

[0151] The following table provides P0=1atm calculated according to the modeling method of the present invention, T0=300K, chemically proper ratio ethylene / air uniform premixed gas two-step reaction parameters and two-step reaction model and elemental reaction model detonation combustion characteristic parameters Compared. Simultaneously figure 1 A comparison of the ZND structure temperature of the mixed gas C-J detonation wave with the two-step reaction model and the calculation results of the elementary reaction model is given. Among them, the detonation wave Mach numbers calculated by the two-step reaction model and the elementary reaction model are kept consistent in the modeling. It can be seen that the two-step reaction model obtained by the modeling method of the present invention can well describe the ZND structure of the detonation wave, and the change trend of the two-step reaction temperature curve is very close to the qualitative result of the elementary reaction,...

specific Embodiment 2

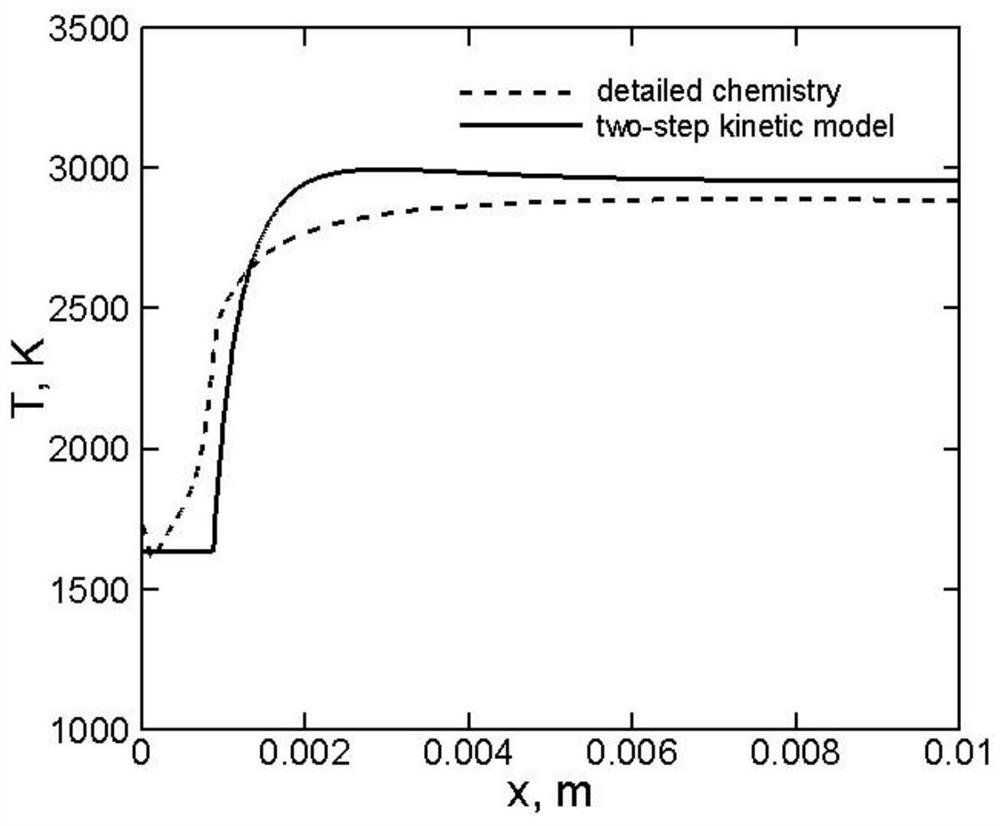

[0157] Further, the table below and figure 2 The modeling method of the present invention for the two-step reaction of macromolecular hydrocarbon fuel JP-10 is compared with the elementary reaction model. Also in the modeling, it is ensured that the detonation wave Mach numbers calculated by the two-step reaction model and the elementary reaction model are consistent. The state and fuel composition parameters corresponding to the modeling are P 0 = 1 atm, T 0 =500K, chemically proper ratio JP-10 / air. The combustion process of macromolecular hydrocarbon fuels is very complex. A typical elementary reaction model contains tens to hundreds of components, and the corresponding reactions are on the order of hundreds to thousands. It is very difficult to directly use it for numerical simulation. The two-step reaction model obtained by the modeling method in this paper can describe the shock wave induction and combustion heat release process corresponding to the detonation combust...

specific Embodiment 3

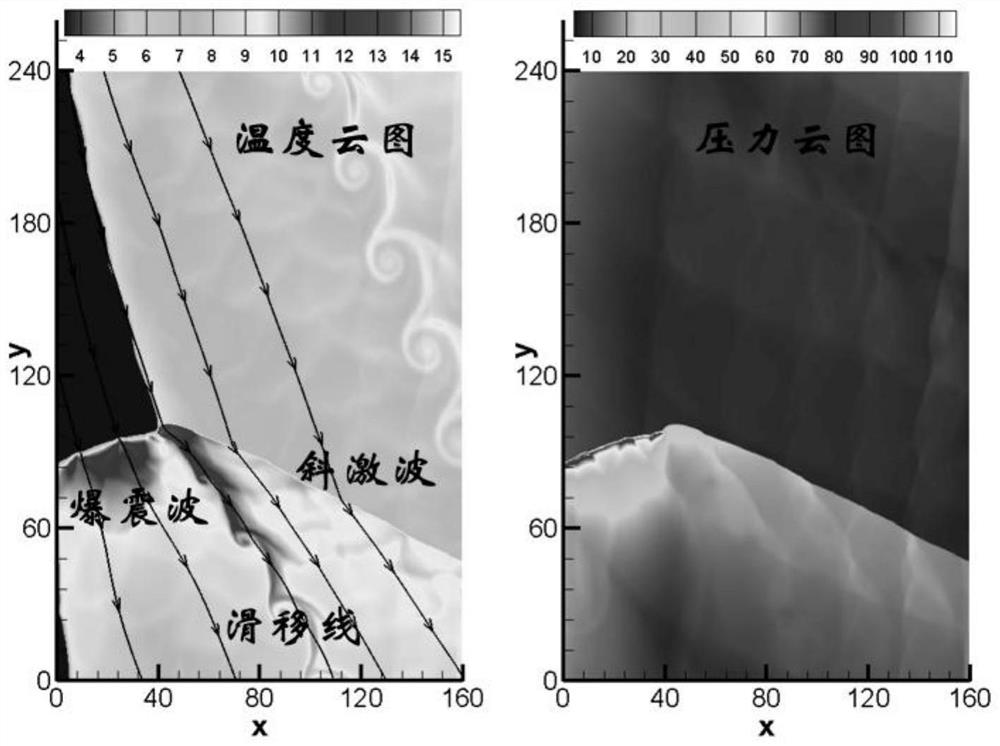

[0163] In order to further verify the two-step reaction model calculation method of the present invention to the actual fuel detonation combustion simulation situation, the two-step reaction model is used to numerically simulate the flow field of the combustion chamber of the rotating detonation engine, and the detonation wave characteristic parameters obtained by the simulation are compared with the basic The results of the meta-reaction model were compared. Also in the modeling, it is ensured that the detonation wave velocity and Mach number calculated by the two-step reaction model and the elementary reaction model are consistent. The state and fuel composition parameters corresponding to the modeling are P0=5500Pa, T0=216K, chemically proper ratio of hydrogen / air premixed gas, wherein the above state parameters correspond to the typical working altitude of the rotary detonation engine H=20km to flow static pressure and static pressure temperature conditions. The following...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com